Selective disproportionation catalyst as well as preparation method and application thereof

A catalyst and selectivity technology, applied in carbon compound catalysts, physical/chemical process catalysts, catalysts, etc., can solve the problems of low conversion rate of toluene and low selectivity of xylene products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

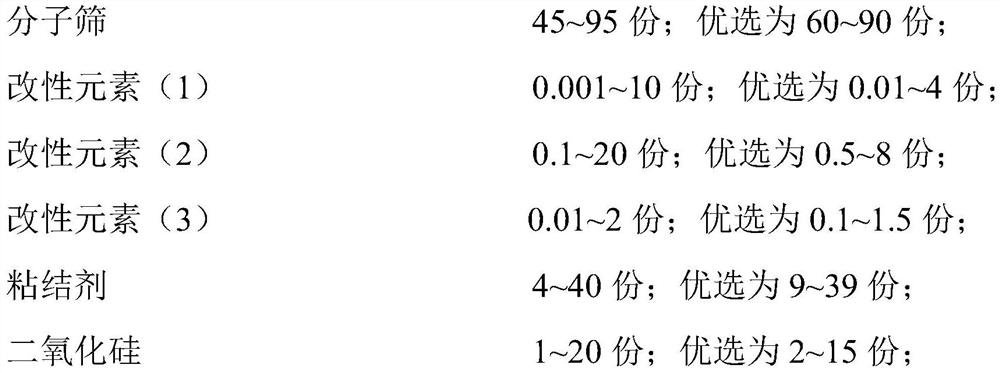

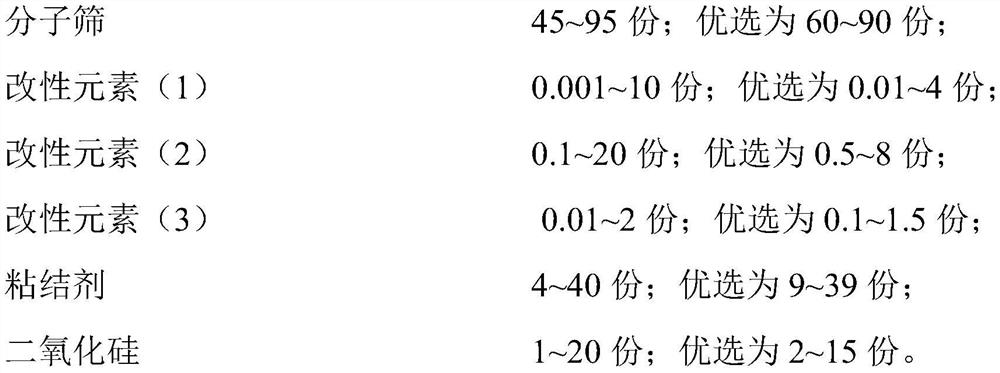

Method used

Image

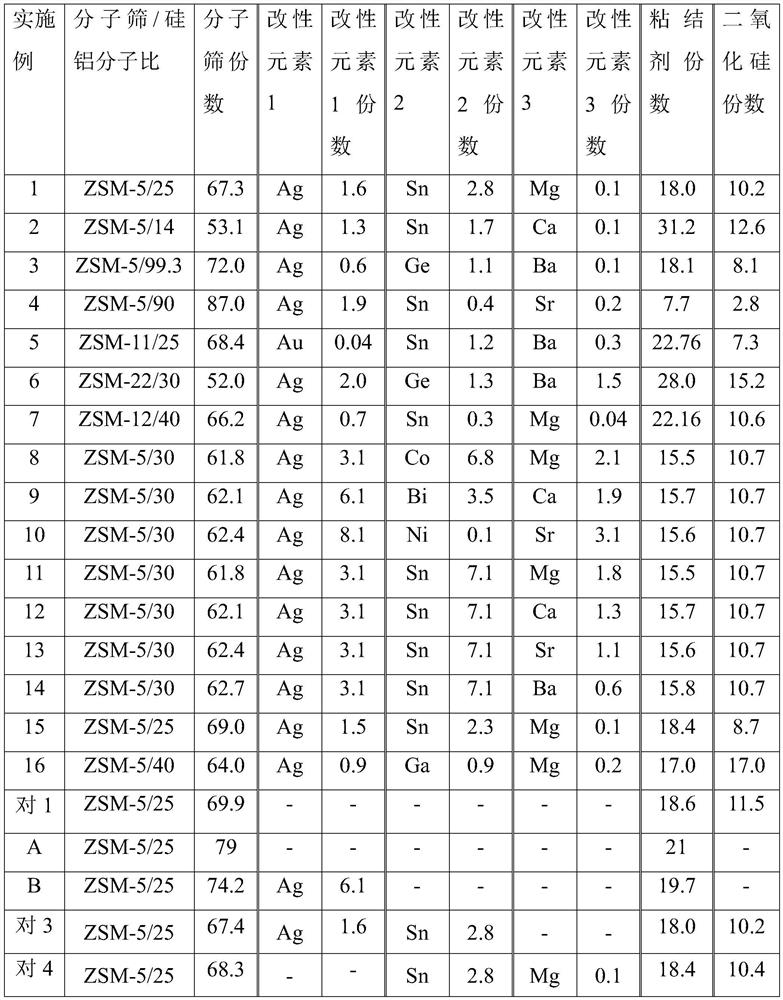

Examples

Embodiment 1

[0069] The ZSM-5 molecular sieve with a silicon-aluminum molecular ratio of 25 (the molecular sieve is provided by Sinopec Catalyst Company, the same below), and the binder silica (from 40% commercially available sodium-free silica sol, the same below) are mixed and dried , 550 DEG C (constant temperature 3 hours) after roasting, obtain the catalyst modification precursor that contains the ZSM-5 molecular sieve of 79% by weight and 21% by weight of binding agent; Get described catalyst precursor 100.0g, take AgNO 3 and Mg(NO 3 ) 2 solution (containing AgNO 3 Weight concentration 5.0%, Mg(NO 3 ) 2 weight concentration 1.5%) 60.0g is impregnated with equal volume at room temperature for 2 hours, dried at 120°C for 6 hours, and continues to take SnSO 4 solution (with SnSO 4 The weight concentration is 10.0%, ) 60.0g is impregnated with equal volume at room temperature for 2 hours, dried at 120°C for 6 hours, and then calcined at 550°C for 3 hours. Continue to modify the cat...

Embodiment 2

[0072] ZSM-5 molecular sieve with a silicon-aluminum molecular ratio of 14, binder silica, mixed, molded, dried, and roasted at 500°C (6 hours) to obtain a ZSM-5 molecular sieve containing 63% by weight and 37% by weight of binder catalyst modification precursor; take the catalyst precursor 100.0g, take AgNO 3 and Ca(NO 3 ) 2 solution (containing AgNO 3 Weight concentration 3.9%, Ca(NO 3 ) 2 Weight concentration 1.0%) 60.0g is impregnated with equal volume at room temperature for 2 hours, dried at 120°C for 6 hours, and continues to take SnSO 4 60.0 g of the solution (with a weight concentration of 6.0%) was impregnated with equal volume at room temperature for 2 hours, dried at 120° C. for 6 hours, and then calcined at 550° C. for 3 hours. Continue to modify the catalyst prepared above, adopt Dow Corning 710 silicone oil 45.0g (weight concentration 40%, solvent No. 90, no aromatic hydrocarbon solvent) to immerse in equal volume at 90°C for 9 hours, keep the temperature a...

Embodiment 3

[0075] ZSM-5 molecular sieve with a silicon-aluminum molecular ratio of 99.3, binder silica and alumina (from pseudo-boehmite, commercially available) were mixed and formed, dried, and calcined at 600°C (constant temperature for 2 hours) to obtain The catalyst modification precursor of the ZSM-5 molecular sieve of 80% by weight and 10% by weight of silicon dioxide and 10% by weight of aluminum oxide; Get described catalyst precursor 100.0g, get AgClO 3 solution and Ba(NO 3 ) 2 solution (containing AgClO 3 Weight concentration 2%, Ba(NO 3 ) 2 Weight concentration: 0.5%) 60.0g is impregnated with equal volume at room temperature for 2 hours, dried at 120°C for 6 hours, and then calcined at 550°C for 3 hours. Continue to take GeCl 4 60.0 g of the solution (with a weight concentration of 6.0%) was impregnated with equal volume at room temperature for 2 hours, dried at 120° C. for 6 hours, and then calcined at 550° C. for 3 hours. Continue to modify the catalyst prepared abov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com