Solvent-free epoxy self-repairing anticorrosive coating as well as preparation method and application thereof

An anti-corrosion coating and self-repairing technology, which is applied in the direction of anti-corrosion coatings, epoxy resin coatings, fire-proof coatings, etc., can solve the extremely high requirements for coating resistance to cathodic disbondment, poor cathodic disbondment resistance of coatings, and shorten the service life of coatings and other problems, to achieve the effect of improving cathodic disbonding resistance, improving anti-corrosion ability, and improving wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

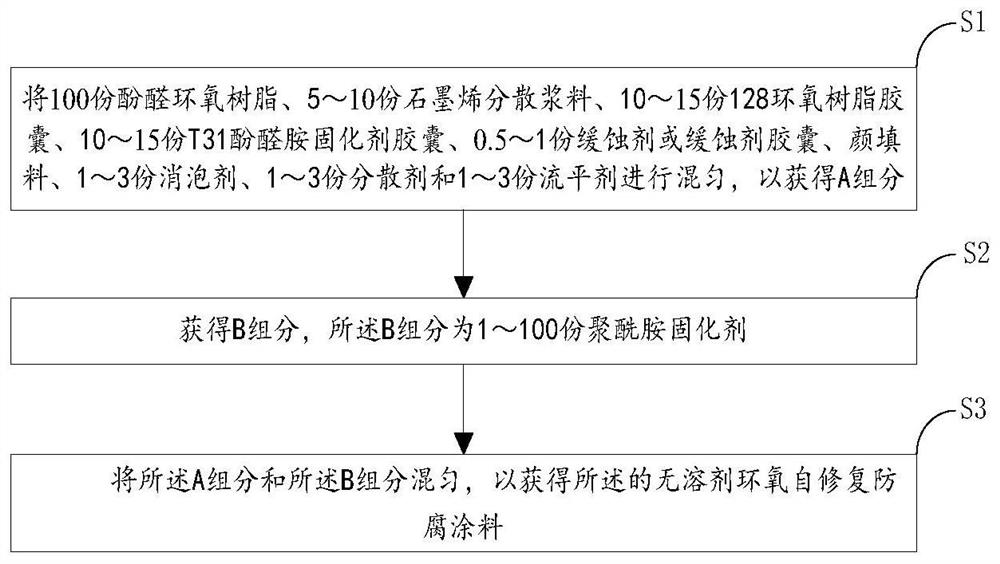

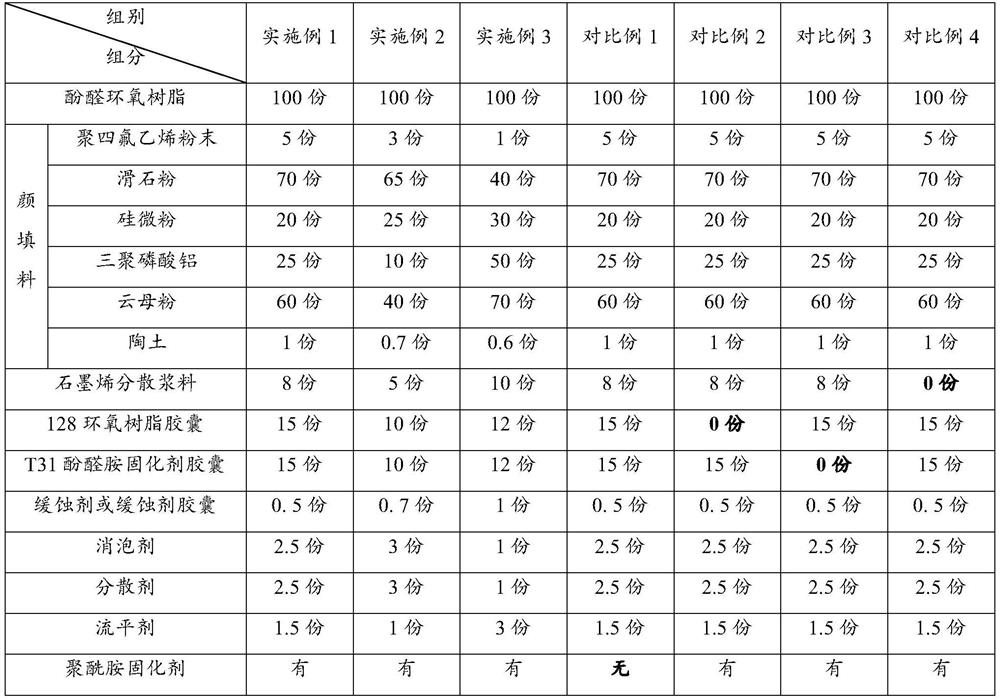

[0036] The raw materials for the preparation of component A include, in parts by weight: 100 parts of novolac epoxy resin, 5-10 parts of graphene dispersion slurry, 10-15 parts of 128 epoxy resin capsules, 10-15 parts of T31 phenalkamine curing agent capsule, 0.5-1 part of corrosion inhibitor or corrosion inhibitor capsule, pigments and fillers, 1-3 parts of defoamer, 1-3 parts of dispersant and 1-3 parts of leveling agent;

[0037] The B component is a polyamide curing agent;

[0038] In this embodiment,

[0039] 100 parts novolac epoxy resin and polyamide curing agent: the combination of novolac epoxy resin (higher functionality) and polyamide curing agent (lower viscosity and better flexibility) makes the coating have the characteristics of traditional solvent-based novolac epoxy coatings. Good chemical stability, heat resistance, acid resistance, alkali resistance, wear resistance, etc., also has good flexibility, impact resistance, low VOC emissions and good construction...

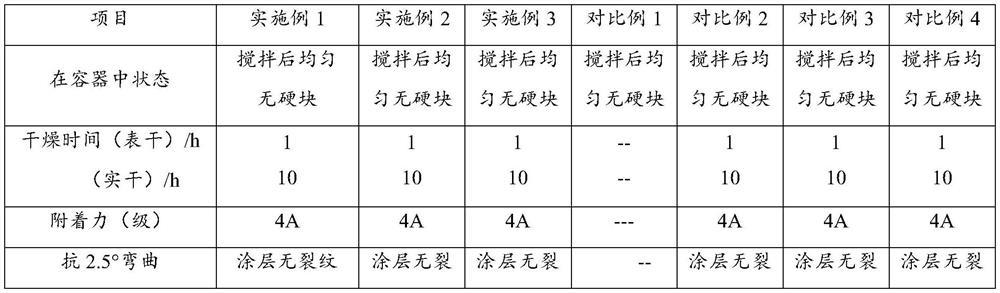

Embodiment 1

[0082] Embodiments of the present invention provide a solvent-free epoxy self-healing anti-corrosion coating and a preparation method thereof, the method comprising:

[0083] 1. Put 100 parts of novolac epoxy resin into a 40°C oven for 5 hours to preheat to obtain preheated novolac epoxy resin;

[0084] 2. Put 5 parts of polytetrafluoroethylene powder, 70 parts of talc powder, 20 parts of silicon micropowder, 25 parts of aluminum tripolyphosphate, 60 parts of mica powder and 1 part of pottery clay in a high-temperature box at 150°C for the second time Heating for 12 hours to obtain paint pigments and fillers;

[0085] 3. Mix the preheated novolac epoxy resin, 2.5 parts of defoamer, 2.5 parts of dispersant, and 1.5 parts of leveling agent and stir at room temperature, add the paint pigment and filler while stirring, and continue stirring at high speed 30 to 40 minutes to disperse the components evenly, then grind for 0.5 to 1 hour with a grinder, and finally add 15 parts of 12...

Embodiment 2

[0089] Embodiments of the present invention provide a solvent-free epoxy self-healing anti-corrosion coating and a preparation method thereof, the method comprising:

[0090] 1. Put the novolac epoxy resin into a 40°C oven for 5 hours to preheat to obtain preheated novolac epoxy resin;

[0091] 2. Put 3 parts of polytetrafluoroethylene powder, 65 parts of talc powder, 25 parts of silicon micropowder, 10 parts of aluminum tripolyphosphate, 40 parts of mica powder and 0.7 parts of clay in a high-temperature box at 150 ° C for the second time Heating for 12 hours to obtain paint pigments and fillers;

[0092] 3. Mix 100 parts of the preheated novolac epoxy resin, 3 parts of defoamer, 3 parts of dispersant, and 1 part of leveling agent, then stir at room temperature, add paint pigments and fillers while stirring, and continue stirring at high speed 30 to 40 minutes to disperse the components evenly, then grind for 0.5 to 1 hour with a grinder, and finally add 10 parts of 128 epox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Impact resistance | aaaaa | aaaaa |

| Epoxy equivalent | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com