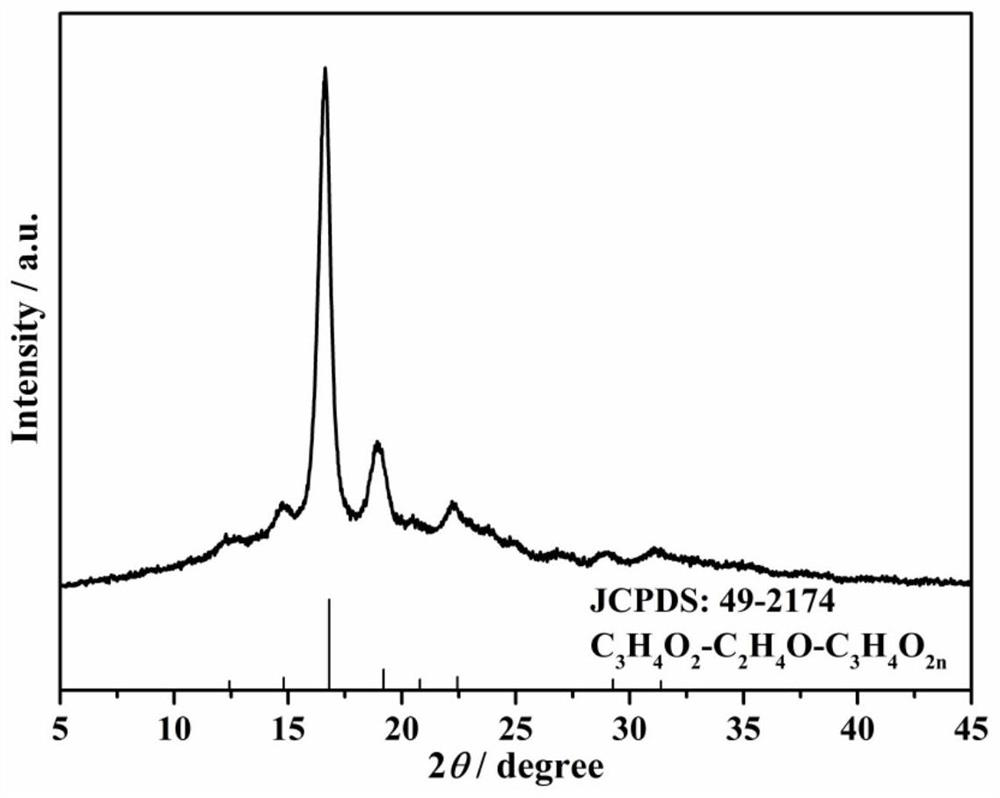

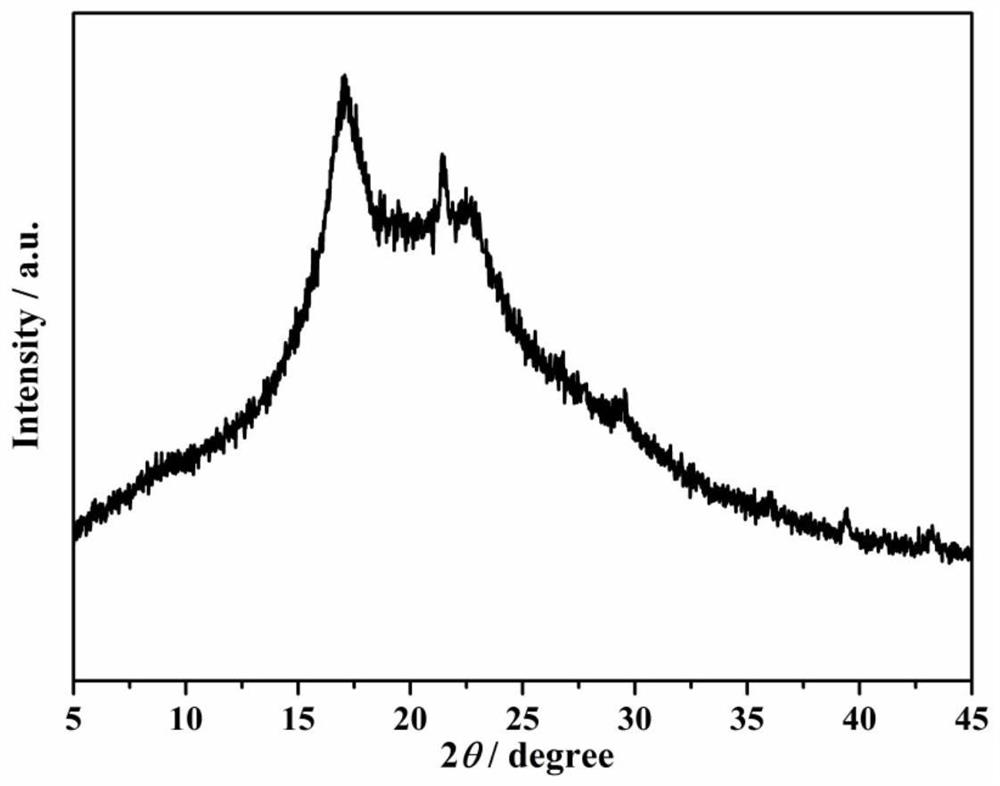

A kind of biogel electrolyte composed of pan and modified plla and preparation method thereof

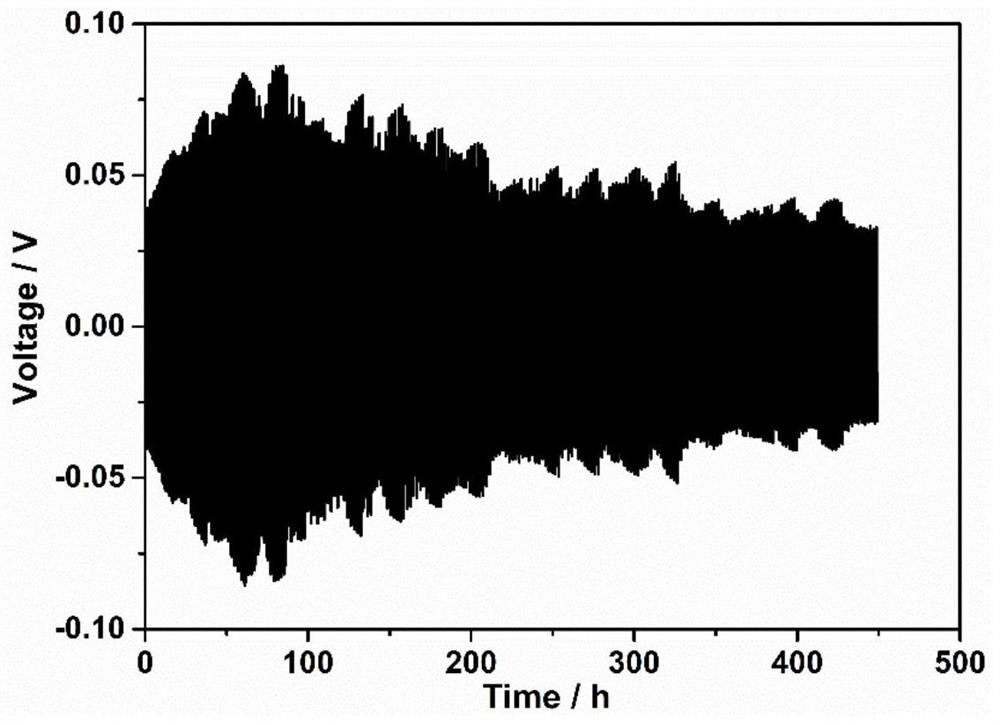

A biogel and electrolyte technology, applied in the field of material chemistry, can solve the problems affecting the electrochemical stability and safety of batteries, the uneven distribution of polymer membrane pores, and the low mechanical strength of polymer membranes, so as to improve the electrochemical performance , stable mechanical strength, good amorphous effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The invention provides a method for preparing a PAN / P (LLA-EG) bio-based gel polymer electrolyte, comprising the following steps:

[0041] (1) Press V CH3Cl2 :V DMF =0.5:1 volume ratio (total volume is 60mL) respectively measure the dichloromethane (CH 3 Cl 2 ) and N,N-dimethylformamide (DMF) solvent were added into a beaker and stirred to obtain a mixed solvent, 1g of PLLA powder was weighed and added to the mixed solvent and stirred at room temperature until completely dissolved to obtain a PLLA solution;

[0042] (2) press n EG :n PLLA The mol ratio of =2:1 measures the ethylene glycol solution of corresponding volume and adds in the PLLA solution of step (1) gained under stirring condition, obtains P (LLA-EG) mixed suspension;

[0043] (3) press m SnCl2 :m PLLA+EG =0.05:1 takes by weighing the stannous chloride of corresponding quality and adds in the P (LLA-EG) mixed suspension of step (2) gained;

[0044] (4) Transfer the P(LLA-EG) mixed suspension obtaine...

Embodiment 2

[0051] The invention provides a structural design and preparation of a PAN / P (LLA-EG) bio-based gel polymer electrolyte, comprising the following steps:

[0052] (1) Press V CH3Cl2 :V DMF = 1:1 volume ratio (total 60mL) measure the corresponding volume of dichloromethane (CH 3 Cl 2 ) and N,N-dimethylformamide (DMF) solvent were added into a beaker and stirred to obtain a mixed solvent, 1g of PLLA powder was weighed and added to the mixed solvent and stirred at room temperature until completely dissolved to obtain a PLLA solution;

[0053] (2) press n EG :n PLLA The mol ratio of=2.5:1 measures the ethylene glycol solution of corresponding volume and adds in the PLLA solution of step (1) gained under stirring condition, obtains P (LLA-EG) mixed suspension;

[0054] (3) press m SnCl2 :m PLLA+EG =0.05:1 takes by weighing the stannous chloride of corresponding quality and adds in the P (LLA-EG) mixed suspension of step (2) gained;

[0055] (4) Transfer the P(LLA-EG) mixed s...

Embodiment 3

[0061] The invention provides a structural design and preparation of a PAN / P (LLA-EG) bio-based gel polymer electrolyte, comprising the following steps:

[0062] (1) Press V CH3Cl2 :V DMF = 3:1 volume ratio (total 60mL) to measure the corresponding volume of dichloromethane (CH 3 Cl 2 ) and N,N-dimethylformamide (DMF) solvent were added into a beaker and stirred to obtain a mixed solvent, 1g of PLLA powder was weighed and added to the mixed solvent and stirred at room temperature until completely dissolved to obtain a PLLA solution;

[0063] (2) press n EG :n PLLA The mol ratio of =3:1 measures the ethylene glycol solution of corresponding volume and adds in the PLLA solution of step (1) gained under stirring condition, obtains P (LLA-EG) mixed suspension;

[0064] (3) press m SnCl2 :m PLLA+EG =0.08:1 takes by weighing the stannous chloride of corresponding quality and adds in the P (LLA-EG) mixed suspension of step (2) gained;

[0065] (4) Transfer the P(LLA-EG) mixed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com