Amiodarone hydrochloride nanosuspension as well as preparation method and application thereof

A technology of nano-suspension and amiodarone hydrochloride, which is applied in the field of medicine, can solve the problems of poor water solubility and difficulty in forming highly dispersed particle groups, and achieve the effects of less excipients, high product uniformity and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

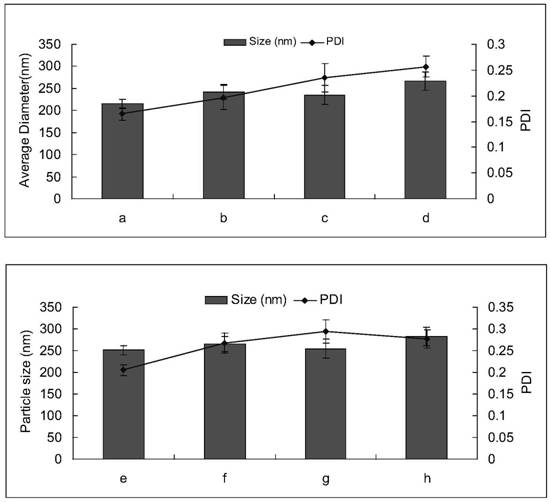

[0063] The following is the screening process of the preparation process of the nanosuspension of the present invention.

[0064] 1. Screening of wet grinding method stabilizer (surfactant)

[0065] Description of the preparation process of amiodarone hydrochloride nanosuspension by wet grinding:

[0066] Take an appropriate amount of amiodarone hydrochloride and a surfactant in a ball mill jar, and add an appropriate amount of ultrapure water. After sealing the ball mill jar, fix it on the ball mill, and set the appropriate speed and time. After the ball milling process is finished, filter and separate the ball milling medium and the compound solution to obtain a nanosuspension solution.

[0067] The contriver is by investigating the impact of different factors (kind and amount of surfactant, grinding speed and grinding time) on the nanosuspension stability, with form, particle size and polydispersity index (PI) as evaluation index, come Determine the best prescription.

...

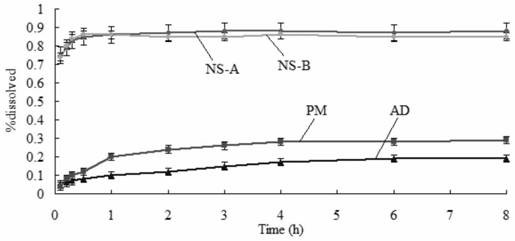

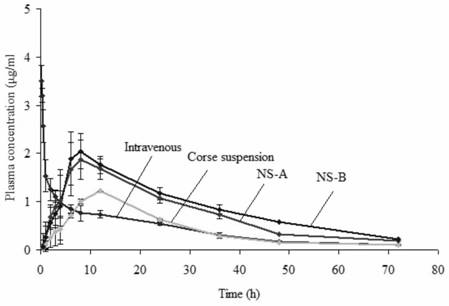

Embodiment 1

[0135] Dissolve 0.3g of PVP and 0.08g of SDS in 20mL of purified water to obtain a solution; disperse 0.8g of amiodarone hydrochloride into the above solution to prepare a common suspension; add the obtained common suspension to a ball mill, And add 20g of zirconia particles with a diameter of 0.2mm; after the ball mill jar is sealed, put it in the ball mill, set the speed at 35Hz, and grind for 6 hours; then use a glass sand funnel to filter out the zirconia particles to obtain amiodarone hydrochloride nanosuspension. The measured particle diameter is: 204.5nm, and the PDI is 0.217. Then add 5% mannitol, divide the sample into 2 mL vials, pre-freeze at -80°C for 12 hours, and then freeze-dry in a freeze dryer for 24 hours to obtain a loose freeze-dried powder, then add purified water After reconstitution, the particle size increased within 5%.

Embodiment 2

[0137] Dissolve 0.35g of PVP and 0.15g of SDS in 20mL of purified water to obtain a solution; disperse 0.8g of amiodarone hydrochloride into the above solution to prepare a common suspension; add the obtained common suspension to a ball mill and add 20g of zirconia particles with a diameter of 0.2mm; after the ball mill jar is sealed, put it into a ball mill, set the speed at 35Hz, and grind for 8 hours; then use a glass sand funnel to filter out the zirconia particles to obtain ammonium hydrochloride Iodine ketone nanosuspension; the measured particle size is: 321.9nm, and the PDI is 0.298.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com