Multi-functional hydrogel triggered by lignin phenolic resin silver-loaded nano spheres as well as preparation method and application thereof

A technology of phenolic resin and lignin, which is applied in the field of preparation of multifunctional hydrogels, can solve the problems of single function, long hydrogel gelation time, harsh reaction conditions, etc., and achieve wide sources, excellent water dispersibility, The effect of high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

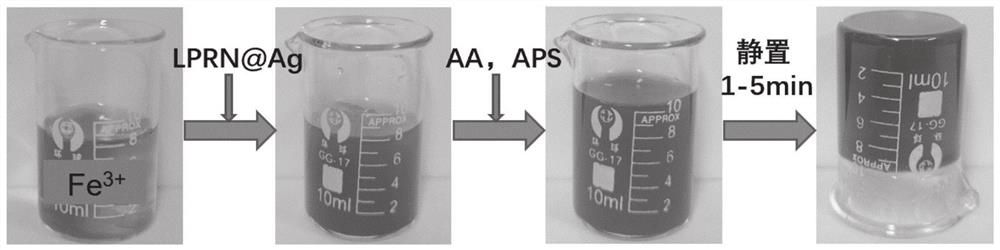

[0034] In one or some embodiments of the present invention, a method for preparing a lignin composite hydrogel is provided, comprising the following steps:

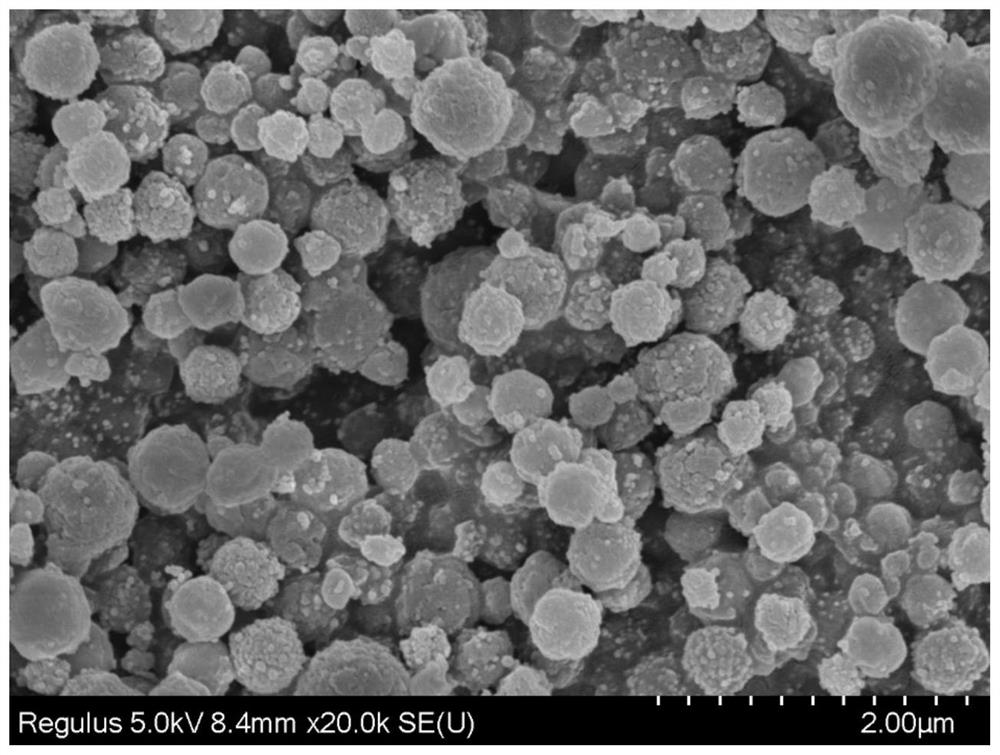

[0035] Dissolving lignin, phenol, formaldehyde and sodium hydroxide in water, and centrifuging and drying the obtained solution after hydrothermal curing to obtain lignin phenolic resin nanospheres. The obtained lignin phenolic resin nanospheres were added into silver ammonia solution, stirred at room temperature and then centrifuged and dried to obtain LPRN@Ag.

[0036]The obtained LPRN@Ag and ferric chloride hexahydrate were mixed and stirred evenly in water, then an initiator and a crosslinking agent were added, and the multifunctional hydrogel was obtained by standing at room temperature.

[0037] In one or some embodiments of the present invention, a method for preparing the above-mentioned multifunctional hydrogel containing lignin-phenolic resin-loaded silver nanospheres is provided.

[0038] In one or some embodi...

Embodiment 1

[0063] Preparation of lignin phenolic resin loaded silver nanospheres:

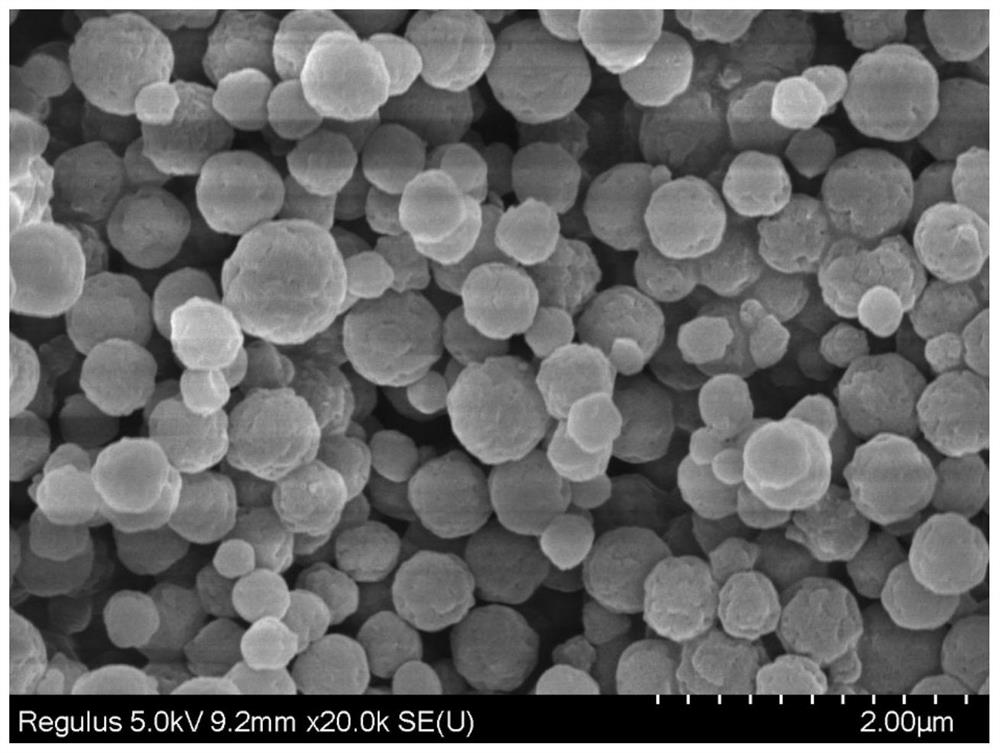

[0064] The lignin-based phenolic resin nanospheres were optimally prepared according to the ratio of lignin to phenol (2:3, w / w). In detail, 0.32g of lignin, 0.48g of phenol, 0.76g of 37% formaldehyde solution and 0.0728g of NaOH were weighed and mixed well in aqueous ethanol (80mL of deionized water and 32mL of ethanol), and then the mixed solution was heated at 65°C Heat for 1 h, then heat at 90°C for 30 minutes. Afterwards, the mixed solution was transferred into a sealed stainless steel autoclave lined with polytetrafluoroethylene, and heated at 120 °C for 12 h, and then naturally cooled to room temperature. The solid product was collected by centrifugation (10000 rpm, 5 min), and washed three times with deionized water and ethanol, respectively. Finally, lignin-phenolic resin nanospheres were obtained by vacuum drying at 80 °C for 12 h.

[0065] Add 2 wt% ammonia solution to 20 mL of 10 mg·mL -1 ...

Embodiment 2

[0069] Preparation of lignin phenolic resin loaded silver nanospheres:

[0070] The lignin-based phenolic resin nanospheres were optimally prepared according to the ratio of lignin to phenol (2:3, w / w). In detail, 0.32g of lignin, 0.48g of phenol, 0.76g of 37% formaldehyde solution and 0.0728g of NaOH were weighed and mixed well in aqueous ethanol (80mL of deionized water and 32mL of ethanol), and then the mixed solution was heated at 65°C Heat for 1 h, then heat at 90°C for 30 minutes. Afterwards, the mixed solution was transferred into a sealed stainless steel autoclave lined with polytetrafluoroethylene, and heated at 120 °C for 12 h, and then naturally cooled to room temperature. The solid product was collected by centrifugation (10000 rpm, 5 min), and washed three times with deionized water and ethanol, respectively. Finally, lignin-phenolic resin nanospheres were obtained by vacuum drying at 80 °C for 12 h.

[0071] Add 2 wt% ammonia solution to 20 mL of 10 mg·mL -1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com