Low-thermal-expansion-coefficient insulating adhesive film and preparation method thereof

A low thermal expansion coefficient, insulating film technology, used in adhesives, epoxy resins, film/sheet adhesives, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with the examples, but the embodiments of the present invention are not limited thereto.

[0038] In order to make the above objects, innovations and advantages of the present invention more obvious and understandable, the specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should not be construed as limiting the scope of the present invention.

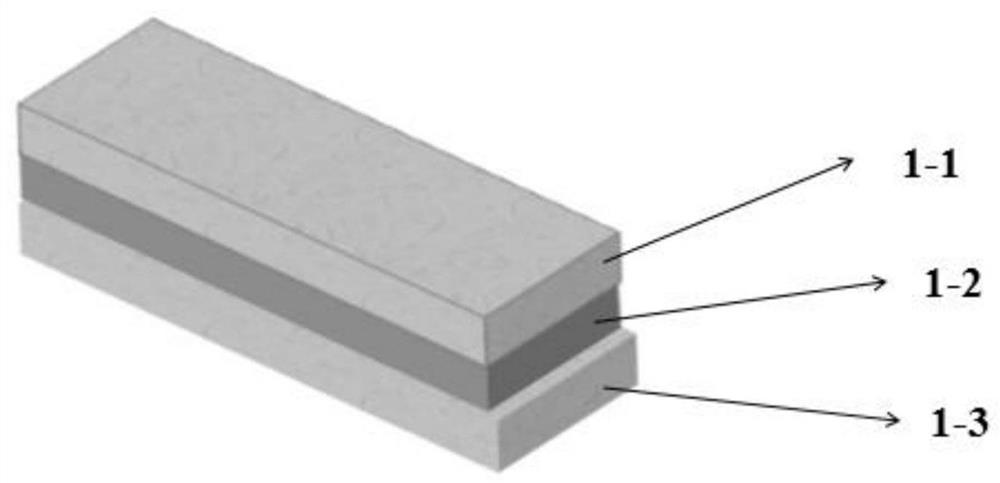

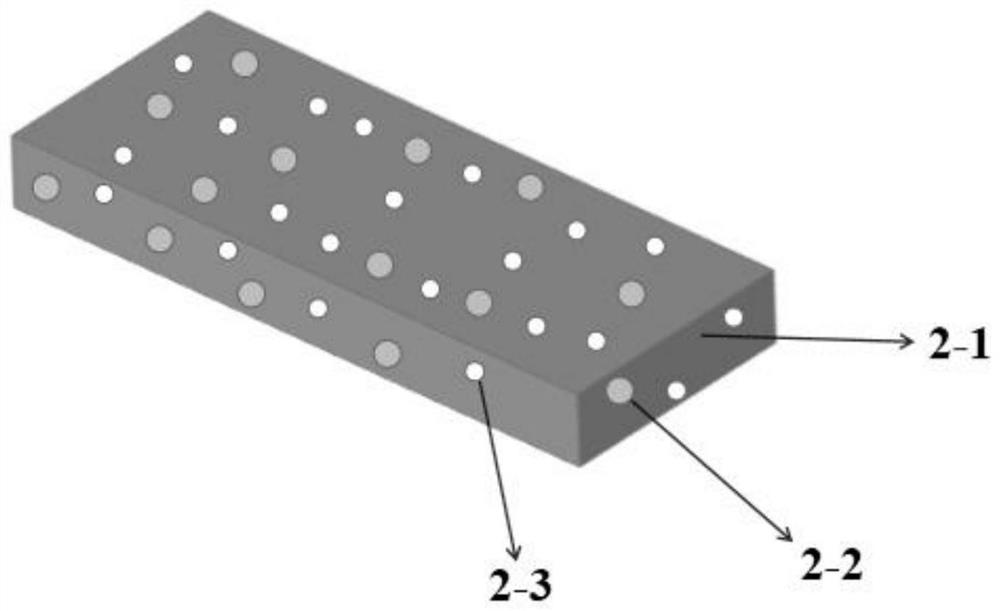

[0039] This embodiment provides a low thermal expansion coefficient insulating adhesive film material suitable for semiconductor packaging and suitable for the preparation of fine lines by additive or semi-additive methods:

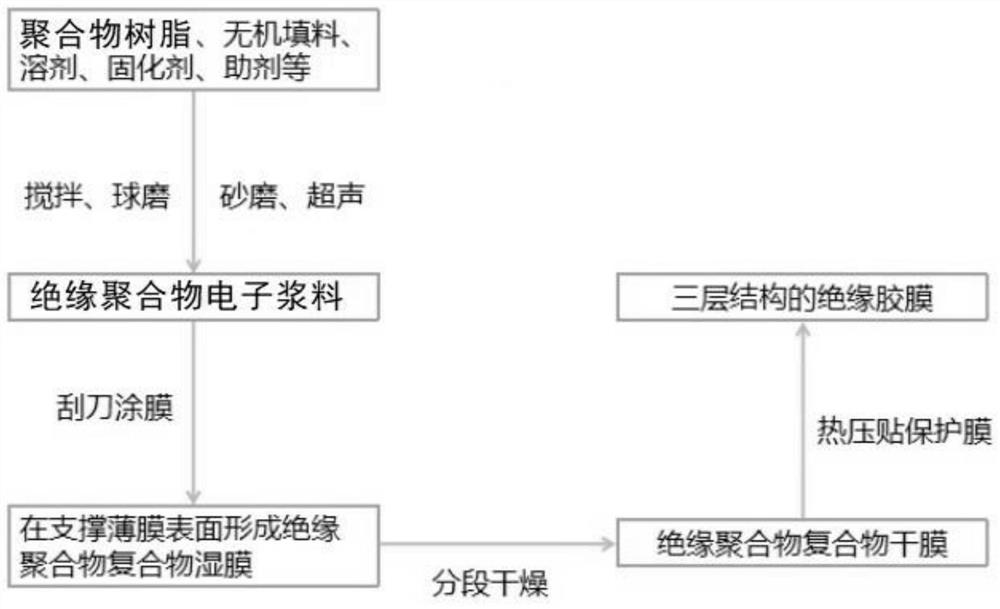

[0040] The following table 1 is respectively the ratio of the insulating polymer electronic paste components of the insulating polymer layer in the insulating adhesive film of Examples 1-4 and Comparative Example 1-2:

[0041]

[0042] The lo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com