Adhesive for medical aluminum foil packaging and its processing technology

A processing technology and adhesive technology, applied in the directions of polymer adhesive additives, non-polymer adhesive additives, adhesive types, etc., can solve the problems of cumbersome dilution process, waste of resources, etc., and achieve low process conditions. , The effect of increasing viscosity and improving adhesive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

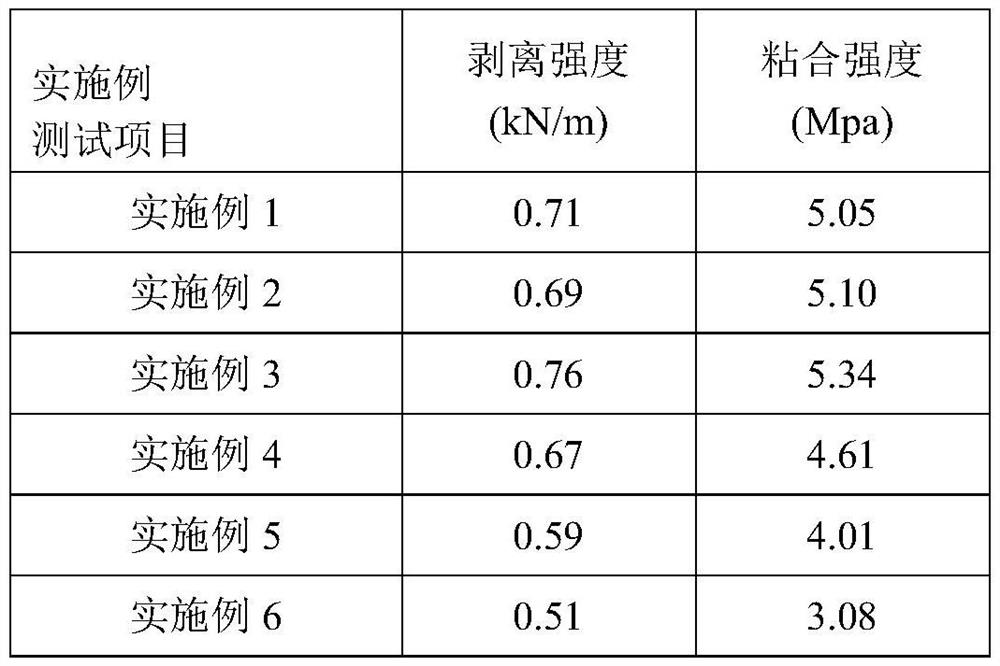

Examples

Embodiment 1

[0019] (1) 1.5 parts of auxiliary emulsifier sorbitan monooleate was added to 5 parts of plasticizer diisononyl phthalate, and then stirred in an oil bath pot at 50 °C for 20 min to obtain a dispersion;

[0020] (2) Subsequently, 5 parts of deionized water dissolved in 2 parts of the main emulsifier polyoxyethylene octylphenol ether-10 are slowly added to the dispersion obtained in step (1), and after the drop addition is completed, the homogenization continues to be homogenized at a speed of 800 rpm in the high-speed disperser for 20 min to form an oil-in-water emulsion;

[0021](3) 50 parts maleic anhydride grafted ethylene propylene monomer rubber, 20 parts high-crystalline polypropylene, 10 parts polyvinyl chloride, 10 parts polyethyleneimide dissolved in xylene and mixed evenly, under nitrogen conditions, 10 parts of highly reactive polybutene, 0.3 parts coupling agent (3-aminopropyl) triethoxysilane was added to the mixed solution, and then the solution was mechanically stir...

Embodiment 2

[0024] (1) 2.25 parts of auxiliary emulsifier dehydrated sorbitol monooleate was added to 7 parts of plasticizer diisononyl phthalate, and then stirred in an oil bath pot at 50 °C for 20 min to obtain dispersion;

[0025] (2) Subsequently, 10 parts of deionized water dissolved in 3 parts of the main emulsifier polyoxyethylene octylphenol ether-10 are slowly added dropwise to the resulting dispersion in step (1), and after the drip addition is completed, the homogenization continues to be homogenized at a speed of 800 rpm in the high-speed disperser for 20 min to form an oil-in-water emulsion;

[0026] (3) 40 parts maleic anhydride grafted ethylene propylene diene monomer rubber, 30 parts highly crystalline polypropylene, 15 parts polyvinyl chloride, 8 parts polyethyleneimide dissolved in xylene and mixed evenly, under nitrogen conditions, 15 parts of highly reactive polybutene, 0.5 parts coupling agent (3-aminopropyl) triethoxysilane was added to the mixed solution, and then the s...

Embodiment 3

[0029] (1) Add 0.75 parts of auxiliary emulsifier sorbitan monooleate to 6 parts of plasticizer diisononyl phthalate, and then stir in an oil bath pot at 50 °C for 20 min to obtain a dispersion;

[0030](2) Subsequently, 8 parts of deionized water dissolved in 1 part of the main emulsifier polyoxyethylene octylphenol ether-10 are slowly added dropwise to the dispersion obtained in step (1), and after the drop addition is completed, the homogenization continues to be homogenized at a speed of 800 rpm in the high-speed disperser for 20 min to form an oil-in-water emulsion;

[0031] (3) 60 parts maleic anhydride grafted ethylene propylene diene monomer rubber, 25 parts high-crystalline polypropylene, 10 parts polyvinyl chloride, 5 parts polyethyleneimide dissolved in xylene and mixed evenly, under nitrogen conditions, 6 parts of highly reactive polybutene, 0.4 parts coupling agent (3-aminopropyl) triethoxysilane was added to the mixed solution, and then the solution was mechanically ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com