Iron-doped molybdenum diselenide nano material with hollow structure as well as preparation method and electro-catalytic nitrogen reduction application thereof

A technology of molybdenum diselenide and nanomaterials, which is applied in the direction of nanotechnology, nanotechnology, and nanotechnology for materials and surface science, and can solve problems such as low nitrogen reduction activity, excellent electrolytic hydrogen evolution performance, and difficult conversion , to achieve the effect of convenient operation, simple preparation method and strong nitrogen adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

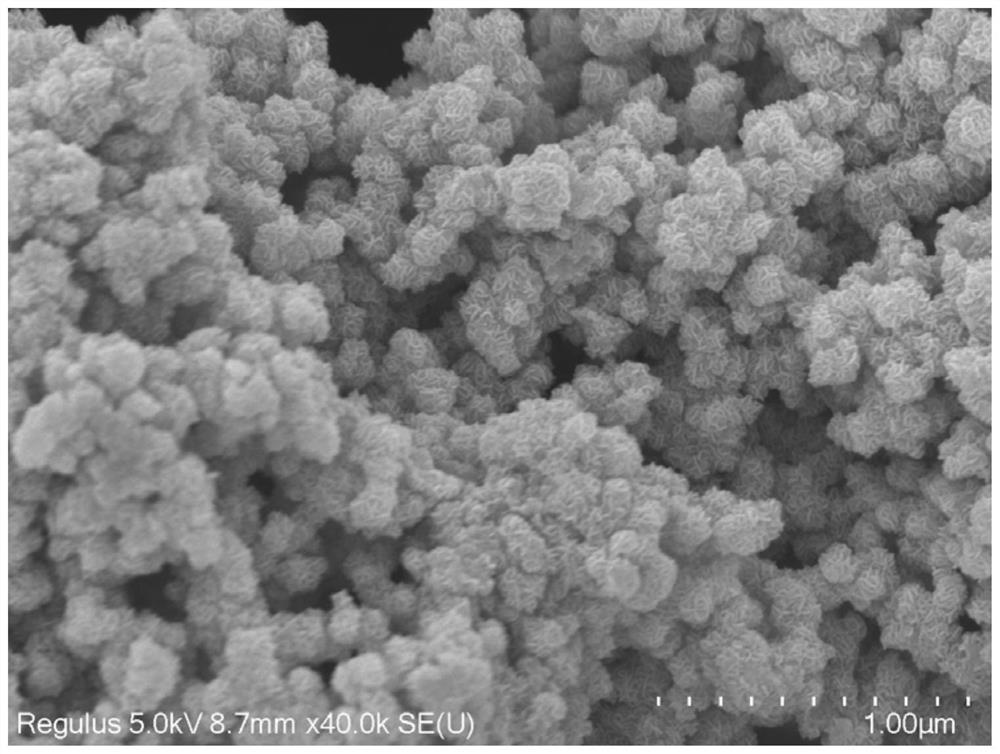

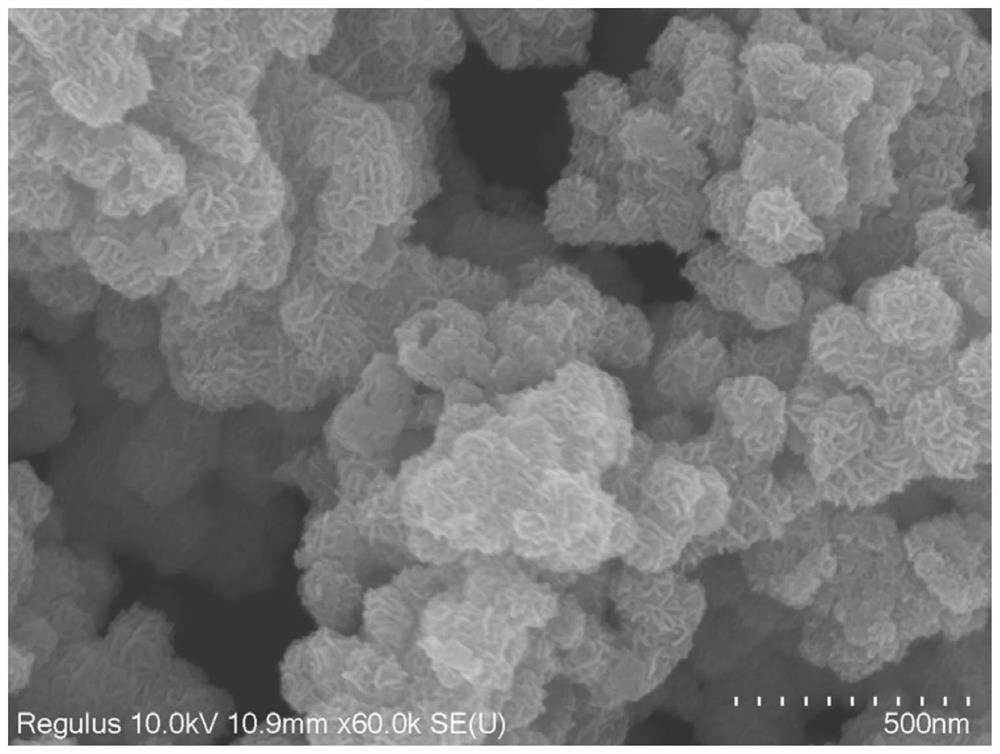

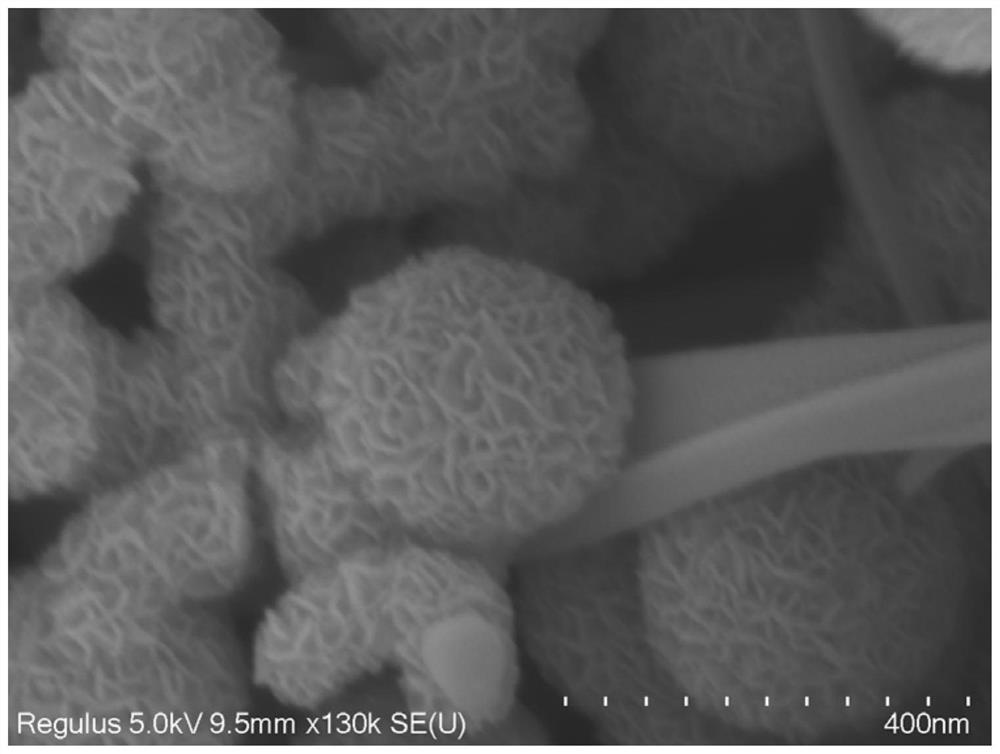

Embodiment 1

[0027] Step 1: Add 0.1mmol of selenium powder to 5mL of hydrazine hydrate and stir for 1h in an oil bath at 80°C. Stir well to form a hydrated selenium precursor; then add 0.054mmol of sodium molybdate dihydrate and 0.006mmol of Iron acetate was dispersed in 15ml of dimethylformamide (DMF) and stirred for 2h, stirred evenly to obtain a metal salt solution; then the cooled hydrated selenium precursor was added dropwise to the above metal salt solution and continued to stir 2h, stirred evenly to obtain a mixed solution; finally, the above mixed solution was transferred to a high-pressure reactor and heated at 180°C for 12h; after the reactor was naturally cooled to room temperature, the obtained product was washed with deionized water until neutral, and then heated at 80°C vacuum drying for 12 hours to obtain the iron-doped molybdenum diselenide nanomaterial with a hollow structure.

[0028] The second step: the iron-doped molybdenum diselenide nanomaterial with hollow structure...

Embodiment 2

[0032] Step 1: Add 0.125mmol of selenium powder to 5mL of hydrazine hydrate and stir for 1h in an oil bath at 80°C, and stir evenly to form a hydrated selenium precursor; then add 0.057mmol of sodium molybdate dihydrate and 0.0063mmol of Iron acetate was dispersed in 15ml of dimethylformamide (DMF) and stirred for 2h to obtain a metal salt solution; then the cooled hydrated selenium precursor was added dropwise to the above metal salt solution and continued to stir for 2h Stir evenly to obtain a mixed solution; finally, transfer the above mixed solution to a high-pressure reactor and heat it at 220°C for 18 hours; after the reactor is naturally cooled to room temperature, wash the obtained product with deionized water until it is neutral, and dry it in vacuum at 70°C 8h, obtaining the iron-doped molybdenum diselenide nanomaterial with a hollow structure.

[0033] The second step: the iron-doped molybdenum diselenide nanomaterial with hollow structure is dispersed in the mixed ...

Embodiment 3

[0037] Step 1: Add 0.15 mmol of selenium powder to 5 mL of hydrazine hydrate and stir for 1 h in an oil bath at 80°C, stirring evenly to form a hydrated selenium precursor; then add 0.063 mmol of sodium molybdate dihydrate and 0.0075 mmol of Iron acetate was dispersed in 15ml of dimethylformamide (DMF) and stirred for 2h, stirred evenly to obtain a metal salt solution; then the cooled hydrated selenium precursor was added dropwise to the above metal salt solution and continued to stir 2h, stirred evenly to obtain a mixed solution; finally, the above solution was transferred to a high-pressure reactor and heated at 200°C for 16h; after the reactor was naturally cooled to room temperature, the obtained product was washed with deionized water to neutrality, and vacuumed at 75°C After drying for 6 hours, the iron-doped molybdenum diselenide nanomaterial with a hollow structure was obtained.

[0038] The second step: the iron-doped molybdenum diselenide nanomaterial with hollow str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com