Preparation method of high-voltage aluminum electrolytic capacitor, and capacitor

A technology of aluminum electrolytic capacitors and capacitors, applied in the direction of electrolytic capacitors, liquid electrolytic capacitors, capacitors, etc., can solve the problems of output power drop, module stability drop, uneven voltage division, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

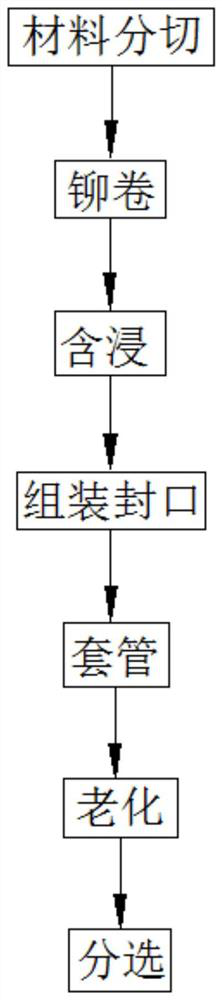

Method used

Image

Examples

preparation example Construction

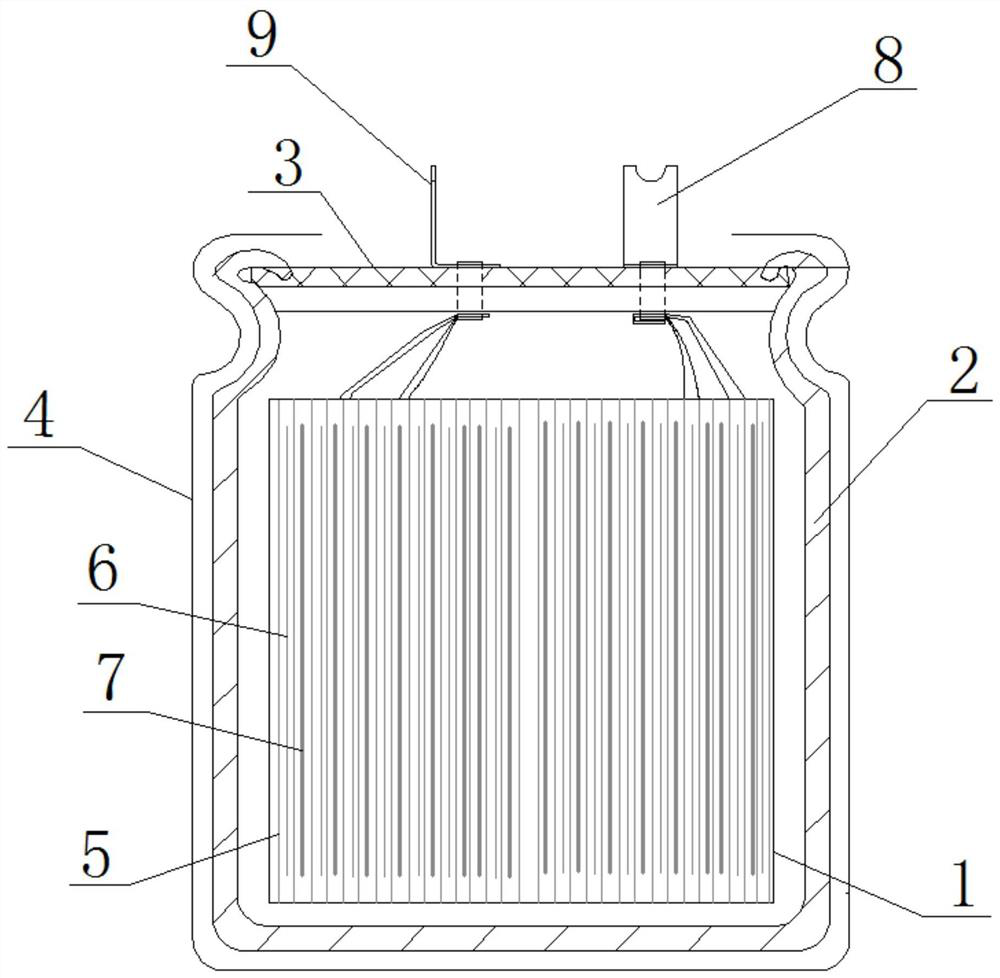

[0076] Such as figure 2 As shown, a capacitor made by the above-mentioned high-voltage aluminum electrolytic capacitor preparation method, the capacitor includes: a core 1 that is sequentially stacked and rolled by cathode foil 6, electrolytic paper 5, and anode foil 7, and the outside of the core 1 is covered with aluminum The shell 2, the cover plate 3 connected to the opening of the aluminum shell 2, the sleeve 4 covered on the outside of the aluminum shell 2, the positive lead-out terminal 8 and the negative lead-out terminal 9 drawn from the core 1 pass through the cover plate 3. The structure design of the capacitor adopts the cathode foil with voltage, double pair of conductive foil strips, and ultrasonic spot welding to improve the current bearing capacity of the capacitor and product reliability. Secondary welding is used between the chaff strip and the lead-out terminal of the cover plate 3 to reduce the riveting resistance and improve the conductivity of the contac...

Embodiment 1

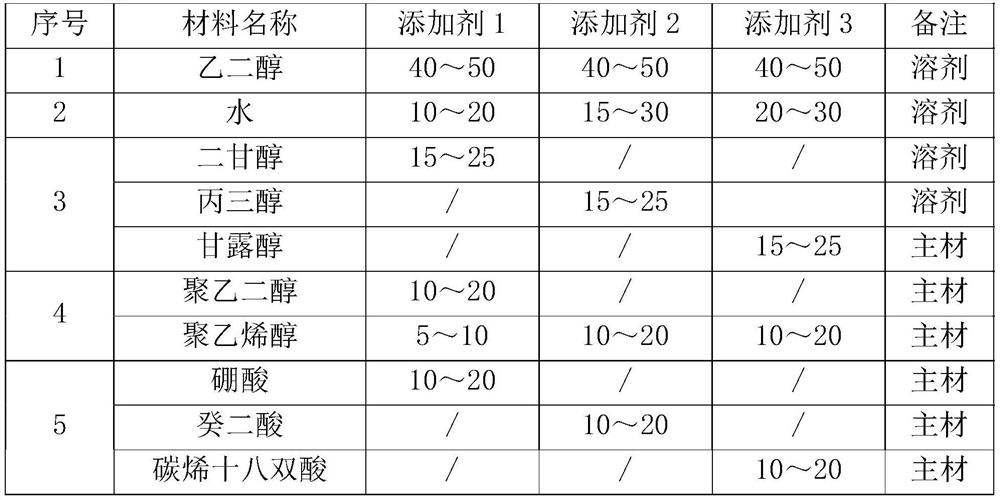

[0093] Additive 1 in embodiment 1, batching comprises by weight: 40~50 parts of ethylene glycol, 10~20 parts of water, 15~25 parts of diethylene glycol, 10~20 parts of polyethylene glycol, 5~10 parts of polyethylene Alcohol, 10-20 parts of boric acid;

[0094] The preparation steps of the additive are as follows:

[0095] First add 40-50 parts of ethylene glycol and 10-20 parts of water into the container, stir, heat to 80±5°C, and keep warm for 30±5 minutes;

[0096] Then add 15-25 parts of diethylene glycol, 10-20 parts of polyethylene glycol, and 5-10 parts of polyvinyl alcohol, stir, heat to 100±5°C, and keep warm for 30±5 minutes.

[0097] Finally, add 10 to 20 parts of boric acid into the container, stir, heat to 120±5°C, keep warm for 12±0.5 hours, and cool down to below 60°C to complete.

[0098] Further, the impregnation step: the electrolyte contains additives,

[0099] The ingredients in the additive include by weight: 40-50 parts of ethylene glycol, 15-30 parts ...

Embodiment 2

[0106]The electrolyte solution includes the following ingredients in parts by weight: 5-10 parts of trimethylamine, 3-5 parts of diethyl carbonate, 3-5 parts of ethyl methyl carbonate, 5-15 parts of sebacic acid, 40-50 parts of ethylene glycol, 10-20 parts of ammonium dodecanoate, 8-15 parts of ammonium sebacate, 1-3 parts of ammonium pentaborate, 5-15 parts of additives, 0.5-1 part of monobutyl phosphate, 0.5-2.5 parts of p-nitrobenzene Methanol, 5-15 parts of nano-silica EG solution;

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com