Preparation method of wear-resistant denitration catalyst for cement denitration and prepared denitration catalyst

A technology of denitration catalyst and anti-wear aid, applied in the field of denitration catalyst, can solve the problems of wear, high dust content of flue gas, catalyst blockage and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

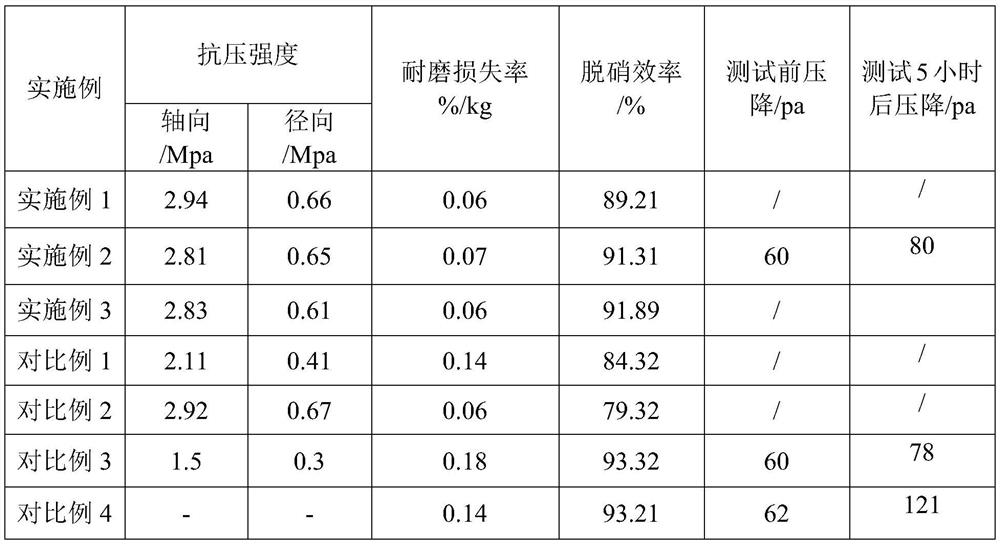

Examples

Embodiment 1

[0031] A method for preparing a wear-resistant denitration catalyst for cement denitration, comprising the following steps:

[0032] (1) Add 5 parts of magnesium chloride to 150 parts of deionized water to obtain magnesium chloride solution, add 100 parts of TiO 2 , while stirring, gradually add ammonia water dropwise to PH = 11, stir for 30 minutes, filter with suction, dry at 60°C, roast at 300°C for 6h, and grind to below 300 mesh to obtain MgO-modified TiO 2 ;

[0033] (2) Get 100 parts of modified TiO in step 1 2 , add 100 parts of 25wt% phosphoric acid solution, heat at 180°C for 16h, filter, dry at 60°C, and calcined at 300°C to obtain phosphoric acid-modified TiO 2 - MgO composite component A;

[0034] (3) Take the waste three-way catalyst powder below 300 mesh, completely immerse it in the aluminum sol with a mass fraction of 25wt% for 10min, then carry out freeze-drying. ℃ roasting to obtain the waste three-way catalyst powder B of alumina coating;

[0035] (4) ...

Embodiment 2

[0041] A method for preparing a wear-resistant denitration catalyst for cement denitration, comprising the following steps:

[0042] (1) Add 3 parts of magnesium chloride to 90 parts of deionized water to obtain magnesium chloride solution, add 100 parts of TiO 2 , while stirring, gradually add ammonia water dropwise to PH = 11, stir for 30 minutes, filter with suction, dry at 60°C, roast at 300°C for 6h, and grind to below 300 mesh to obtain MgO-modified TiO 2 ;

[0043] (2) get 100 parts of modified TiO in step (1) 2 , adding 100 parts of 15wt% phosphoric acid solution, heated at 180°C for 16h, filtered, dried at 60°C, and calcined at 300°C to obtain phosphoric acid-modified TiO 2 - MgO composite component A;

[0044] (3) Take the waste three-way catalyst powder below 300 mesh, completely immerse it in the aluminum sol with a mass fraction of 25wt% for 10min, then carry out freeze-drying. ℃ roasting to obtain the waste three-way catalyst powder B of alumina coating;

[...

Embodiment 3

[0051] A method for preparing a wear-resistant denitration catalyst for cement denitration, comprising the following steps:

[0052] (1) Add 3 parts of magnesium chloride to 90 parts of deionized water to obtain magnesium chloride solution, add 100 parts of TiO 2 , while stirring, gradually add ammonia water dropwise to PH = 11, stir for 30 minutes, filter with suction, dry at 60°C, roast at 300°C for 6h, and grind to below 300 mesh to obtain MgO-modified TiO 2 ;

[0053] (2) Get 100 parts of modified TiO in step 1 2 , adding 100 parts of 15wt% phosphoric acid solution, heated at 180°C for 16h, filtered, dried at 60°C, and calcined at 300°C to obtain phosphoric acid-modified TiO 2 - MgO composite component A;

[0054] (3) Take the waste three-way catalyst powder below 300 mesh, completely immerse it in the aluminum sol with a mass fraction of 25wt% for 10min, then carry out freeze-drying. ℃ roasting to obtain the waste three-way catalyst powder B of alumina coating;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com