Preparation method and application of acetamidine hydrochloride

A technology of acetamidine hydrochloride and acetamidine hydrochloride, which is applied in the field of preparation of acetamidine hydrochloride, can solve the problems of pipeline blockage and high energy consumption, and achieve the effects of high cooling efficiency, large specific surface area, and avoiding side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

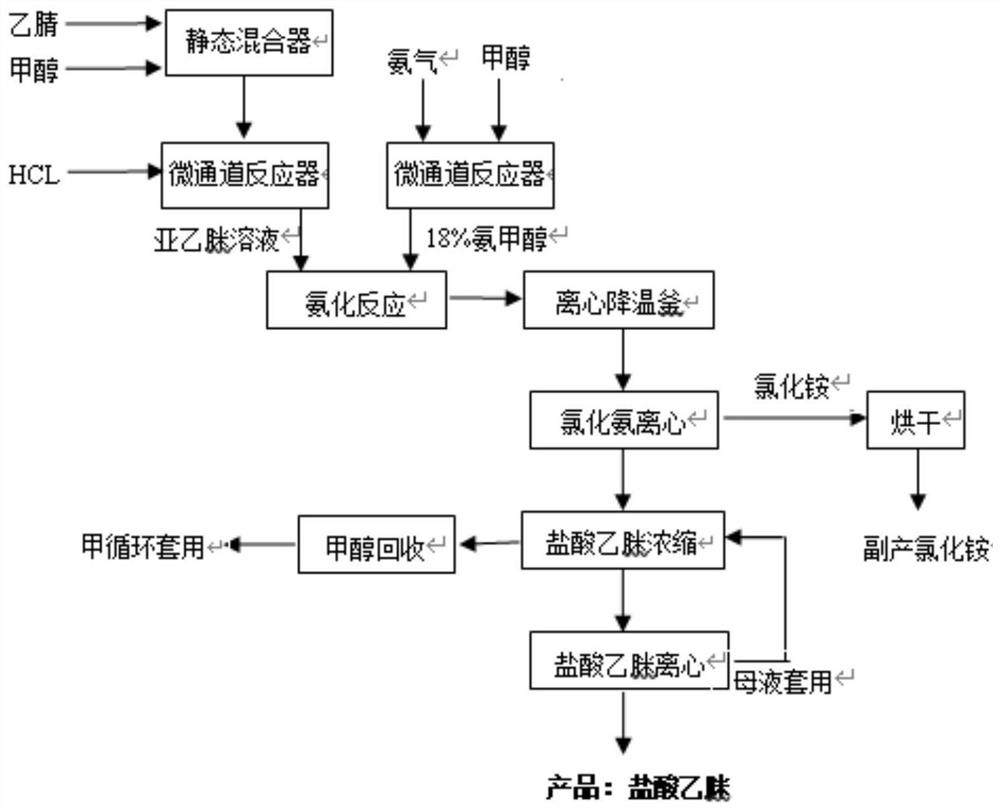

[0046] According to a first aspect of the present invention, a kind of preparation method of acetamidine hydrochloride comprises the following steps:

[0047] a) After acetonitrile is mixed with methanol, it is passed into the first microchannel reactor together with hydrogen chloride for addition reaction to obtain acetamidine;

[0048] B) ammonia and methanol are passed into the second microchannel reactor to react to obtain ammonia methanol;

[0049] c) The acetamidine obtained at the outlet of the first microchannel reactor and the ammonia methanol obtained at the outlet of the second microchannel reactor are simultaneously added to the reactor for ammoniation reaction to obtain acetamidine hydrochloride.

[0050] Step a)

[0051] In a preferred embodiment, the mass ratio of acetonitrile and methanol is 1:1.3-1.4, and its typical but non-limiting mass ratios are, for example, 1:1.30, 1:1.35, and 1:1.40.

[0052] In a preferred embodiment, the mixing of acetonitrile and...

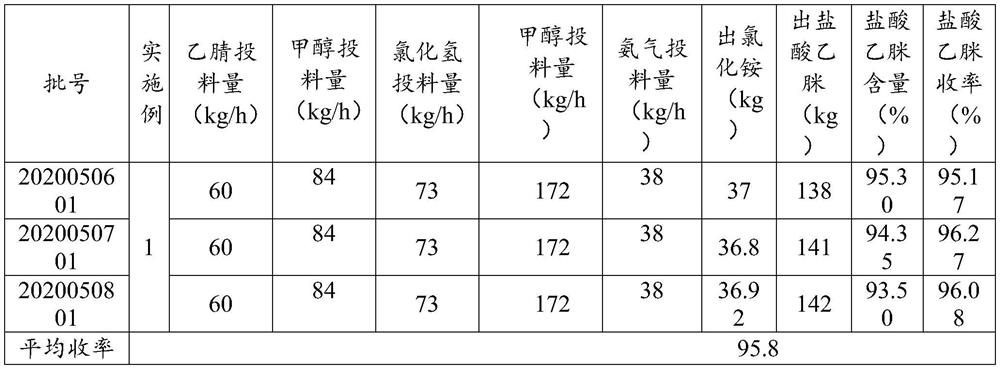

Embodiment 1

[0098] A preparation method of acetamidine hydrochloride, comprising the following steps:

[0099] (1) acetonitrile, methyl alcohol are passed in the first microchannel reactor after static device mixing by the material proportion of table 1, control its residence time 2 hours in the microchannel reactor;

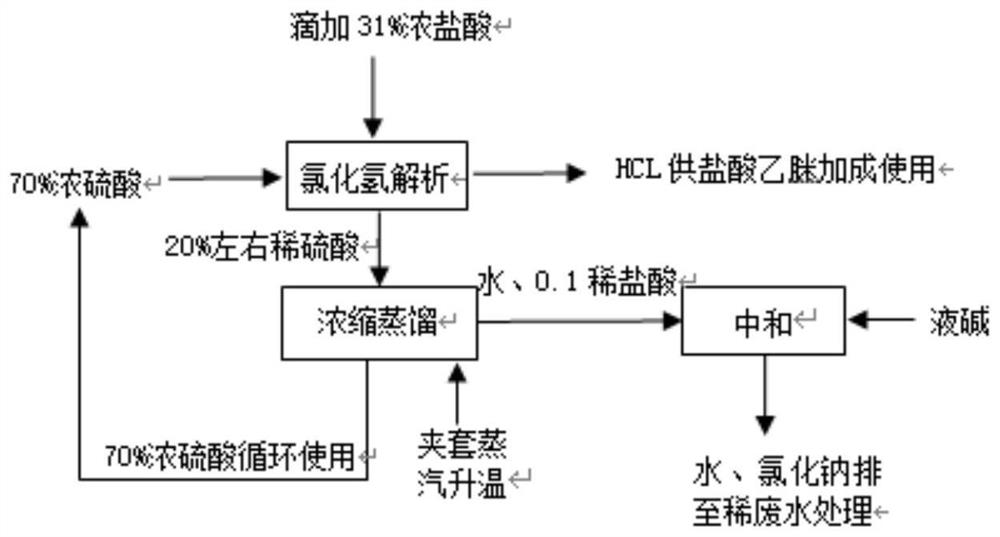

[0100](2) 31% concentrated hydrochloric acid is added dropwise in the vitriol oil of 70%, hydrogen chloride is resolved by the concentrated sulfuric acid dissolution heat, and the hydrogen chloride that resolves is lyophilized and dehydrated, then passes into step ( 1) in the first microchannel reactor, its residence time is consistent with the residence time of acetonitrile and methanol in the first microchannel reactor, and the reaction temperature in the first microchannel reaction is 15~20 ℃, the addition reaction Finally, ethyleneamidine is obtained, wherein the diluted sulfuric acid is concentrated to about 70% by distillation, and hydrogen chloride can be recycled fo...

Embodiment 2

[0108] The difference between this embodiment and Example 1 is that the temperature of the addition reaction in step (2) of the present embodiment is 20-30°C, and the time of the addition reaction is 1-1.5 hours, and all the other operating steps are the same as those in the implementation Example 1 is the same, and the yield of the acetamidine hydrochloride that the present embodiment obtains is 80%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com