Preparation method of ceftriaxone sodium

A technology of ceftriaxone sodium and sodium hydroxide, which is applied in the field of preparation of ceftriaxone sodium, can solve the problems that the content of ceftriaxone sodium does not meet the requirements, and achieve the effects of reducing adverse reactions, improving quality, and shortening reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

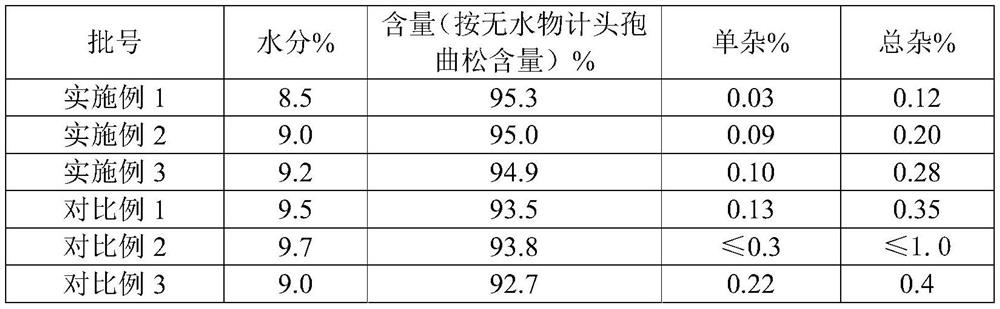

Examples

preparation example Construction

[0034] A kind of preparation method of ceftriaxone sodium, is characterized in that: comprise the steps:

[0035] S1. Mix dichloromethane and alcohols in a ratio of 7:1.8 to 2.2 to obtain the first mixed solution, and cool down to -10 to 0°C;

[0036] S2. Mix dichloromethane and AE active ester in a weight ratio of 70:18-20 to obtain a second mixed solution, and cool down to -5-0°C;

[0037] S3. Mix alcohols, water, triethylamine and 7-ACT in a weight ratio of 14:3:6 to 21:18 to obtain a third mixed solution, and lower the temperature to -5 to 0°C;

[0038] S4. Add the third mixed solution, the second mixed solution and triethylamine to the first mixed solution within 90 to 120 minutes simultaneously to obtain the first reaction solution, and control the temperature at -2 to 0°C to continue the reaction until the end point to 7- ACT residue ≤ 2.0%, the added weight of triethylamine is 0.3-1.1 times of 7-ACT;

[0039] S5, add 20mg / ml aqueous sodium hydroxide solution to the f...

Embodiment 1

[0047] A kind of preparation method of ceftriaxone sodium, described preparation method comprises the following steps:

[0048] S1. Mix 10ml of dichloromethane and 4ml of methanol to obtain the first mixed solution, and cool down to -5°C;

[0049] S2, 50ml of dichloromethane and 19.1g of AE active ester are mixed to obtain the second mixed solution, and the temperature is lowered to -1°C;

[0050] S3, 17ml of methanol, 3ml of water, 3-10ml of triethylamine, 18g of 7-ACT were mixed to obtain the third mixed solution, and the temperature was lowered to -1°C;

[0051] S4. Add the third mixed solution, the second mixed solution and 5-12ml triethylamine to the first mixed solution simultaneously within 90-120 minutes to obtain the first reaction solution, and keep it at -2-0°C to continue the reaction until 7- ACT residue ≤ 2.0%;

[0052] S5. Add 70ml of 20mg / ml sodium hydroxide aqueous solution to the first reaction solution at temperature control -2-0°C, then add 0.5g of sodium...

Embodiment 2

[0060] A kind of preparation method of ceftriaxone sodium, described preparation method comprises the following steps:

[0061] S1. Mix 10ml of dichloromethane and 4ml of ethanol to obtain the first mixed solution, and cool down to -5°C;

[0062] S2, 50ml of dichloromethane and 19.1g of AE active ester are mixed to obtain the second mixed solution, and the temperature is lowered to -1°C;

[0063] S3, 17ml of ethanol, 3ml of water, 3-10ml of triethylamine, 18g of 7-ACT were mixed to obtain the third mixed solution, and the temperature was lowered to -1°C;

[0064] S4. Add the third mixed solution, the second mixed solution and 5-12ml triethylamine to the first mixed solution simultaneously within 90-120 minutes to obtain the first reaction solution, and keep it at -2-0°C to continue the reaction until 7- ACT residue ≤ 2.0%;

[0065] S5. Add 70ml of 20mg / ml sodium hydroxide aqueous solution to the first reaction solution at temperature control -2-0°C, then add 0.5g of sodium m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com