Preparation method of cefuroxime acid

A technology of cefuroxime acid and methoxyiminofuran acetyl chloride dichloromethane, applied in the field of preparation of cefuroxime acid, can solve problems such as poor stability, and achieve the effects of good stability, improved stability and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

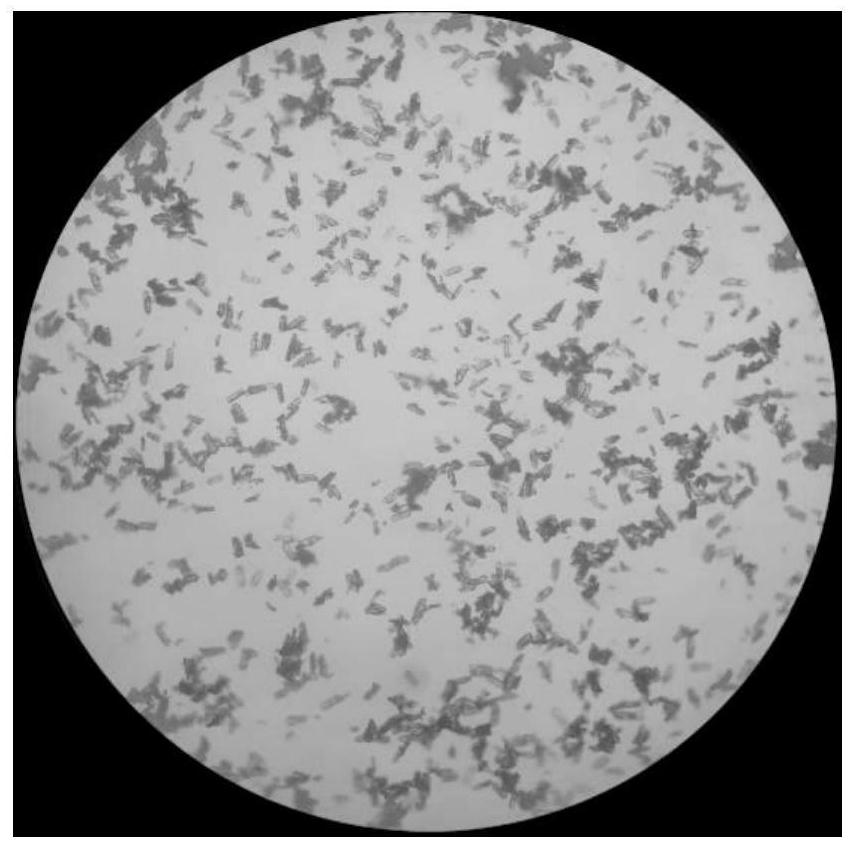

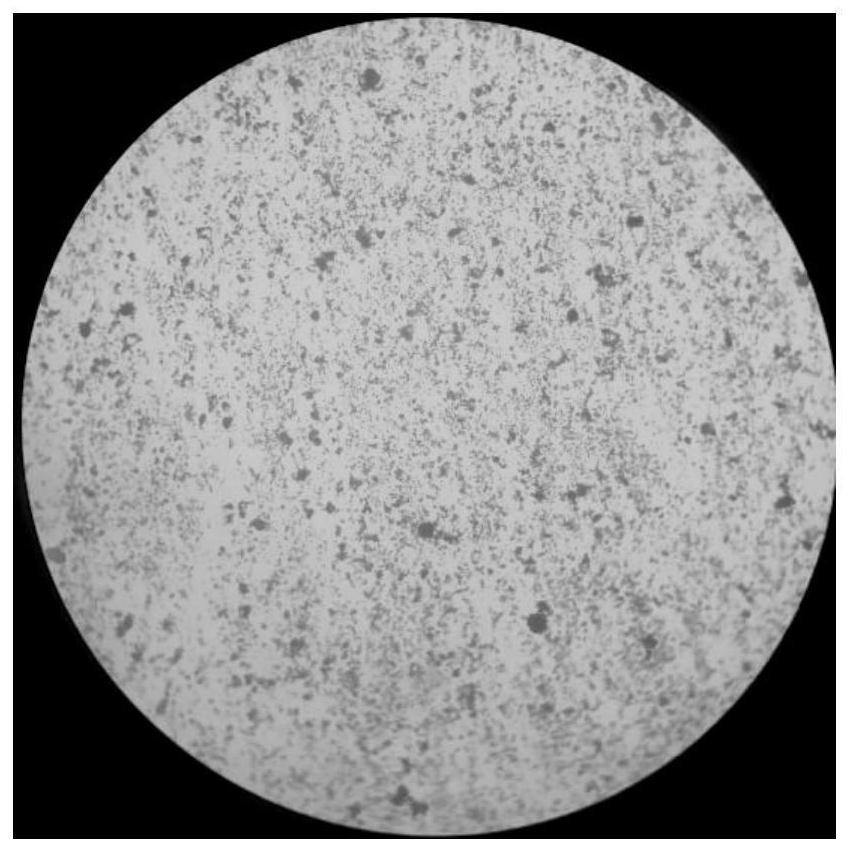

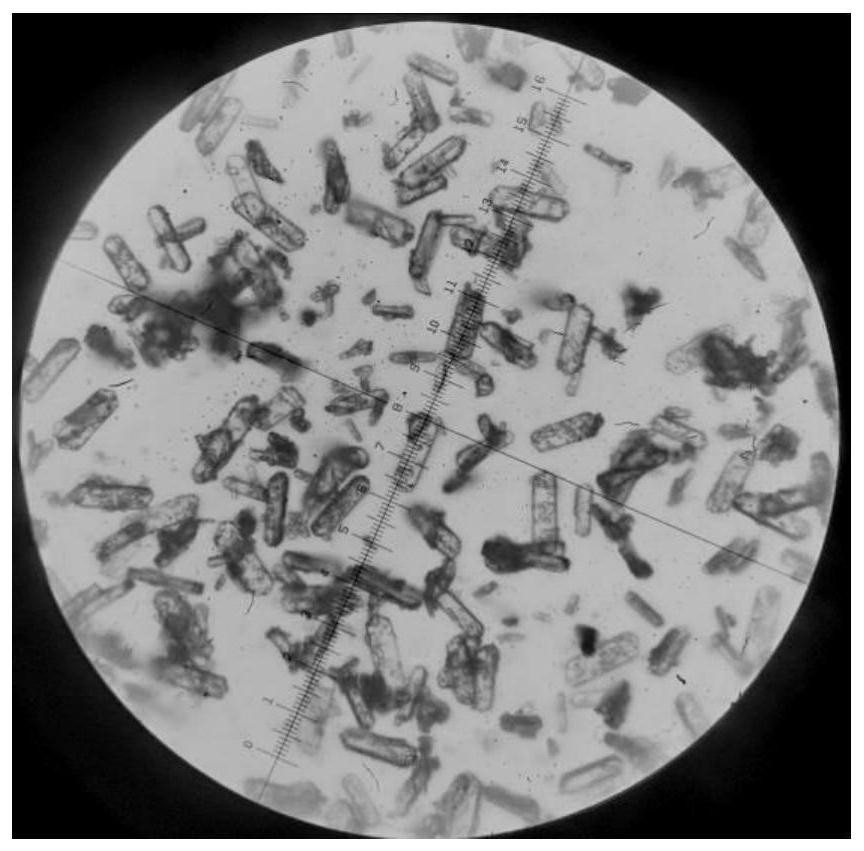

Image

Examples

Embodiment 1

[0054] A preparation method suitable for industrial production of cefuroxime acid, comprising the steps of:

[0055] Step (1): Preparation of MDCC

[0056] Add 120g of purified water and 30g of D-7ACA to a clean and dry reaction bottle, control the temperature at 0-10°C, pH ≤ 10, add 20% sodium hydroxide solution dropwise until dissolved, add dichloromethane of methoxyiminofuranacetyl chloride Methane solution, and use 20% sodium hydroxide to control the pH=6.5~7.5 reaction, react until the residue of D-7ACA meets the requirements, separate to obtain the water phase, add 2g of activated carbon, keep warm at 10~20°C, and decolorize for 30 minutes at pH=5.0~7.0, Filter to crystal bottle.

[0057] Add 100ml of dichloromethane to the crystallization bottle, control the temperature at 10-20°C, slowly add dilute hydrochloric acid dropwise to pH = 1.5-2.2, and grow the crystal for 30 minutes. Filter, wash with purified water and dichloromethane. 46.4g of the product was obtained b...

Embodiment 2

[0061] A preparation method suitable for industrial production of cefuroxime acid, comprising the steps of:

[0062] Step (1): Preparation of MDCC

[0063] Add 120g of purified water and 30g of D-7ACA to a clean and dry reaction bottle, control the temperature at 0-10°C, pH ≤ 10, add 20% sodium hydroxide solution dropwise until dissolved, add dichloromethane of methoxyiminofuranacetyl chloride Methane solution, and use 20% sodium hydroxide to control the pH=6.5~7.5 reaction, react until the residue of D-7ACA meets the requirements, separate to obtain the water phase, add 2g of activated carbon, keep warm at 10~20°C, and decolorize for 30min at pH=5.0~7.0, Filter to crystal bottle.

[0064] Add 100ml of dichloromethane to the crystallization bottle, control the temperature at 10-20°C, slowly add dilute hydrochloric acid dropwise to pH = 1.5-2.2, and grow the crystal for 30 minutes. Filter, wash with purified water and dichloromethane. 46.4 g of the product was obtained by dr...

Embodiment 3

[0068] A preparation method suitable for industrial production of cefuroxime acid, comprising the steps of:

[0069] Step (1): Preparation of MDCC

[0070] Add 120g of purified water and 30g of D-7ACA to a clean and dry reaction bottle, control the temperature at 0-10°C, pH ≤ 10, add 20% sodium hydroxide solution dropwise until dissolved, add dichloromethane of methoxyiminofuranacetyl chloride Methane solution, and use 20% sodium hydroxide to control the pH=6.5~7.5 reaction, react until the residue of D-7ACA meets the requirements, separate to obtain the water phase, add 2g of activated carbon, keep warm at 10~20°C, and decolorize for 30min at pH=5.0~7.0, Filter to crystal bottle.

[0071] Add 100ml of dichloromethane to the crystallization bottle, control the temperature at 10-20°C, slowly add dilute hydrochloric acid dropwise to pH = 1.5-2.2, and grow the crystal for 30 minutes. Filter, wash with purified water and dichloromethane. 46.3g of the product was obtained by dry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com