Method for extracting high-purity fucosan sulfate from brown algae

A fucoidan sulfate, high-purity technology, applied in the field of preparation of fucoidan sulfate, can solve the problems of unsatisfactory purity, low purity and sulfate content of fucoidan sulfate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

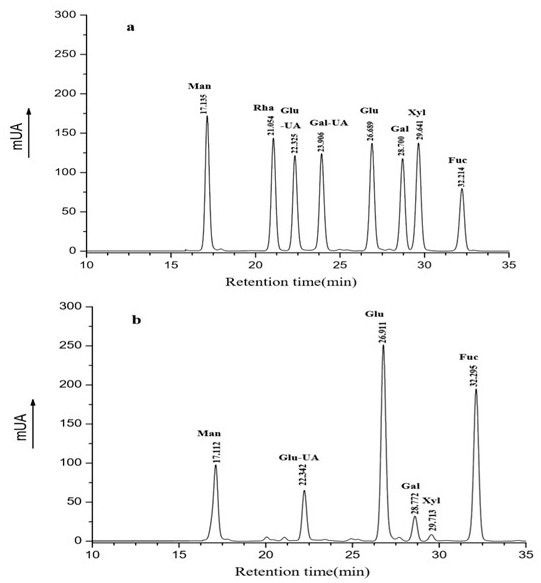

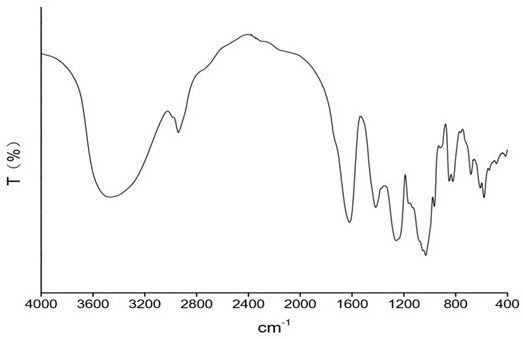

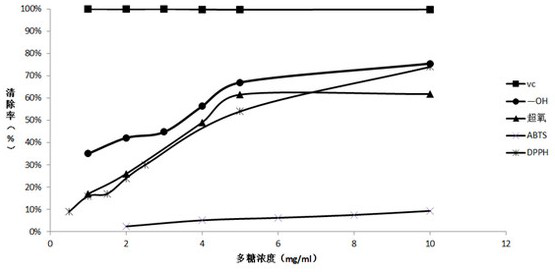

Image

Examples

Embodiment 1

[0023] A kind of method of extracting high-purity fucoidan sulfate ester from brown algae of the present invention, carries out according to following steps successively:

[0024] (1) Wash the fresh kelp to remove impurities such as silt, salt and mannitol on the surface, dry it in a 50°C oven, grind it into powder and pass it through a 60-mesh sieve to obtain kelp powder;

[0025] (2) Add citric acid-sodium citrate buffer solution with a pH of 4.8 into 50 g of kelp powder, and stir while adding to obtain solution I. The mass ratio of the kelp powder to the citric acid-sodium citrate buffer solution is 1 g: 17ml;

[0026] (3) Heat solution I to 50°C, add complex enzyme for enzymolysis for 1.5 hours to obtain solution II, the amount of compound enzyme added is filter paper enzyme activity 34.15 FPU, endocellulase activity 49.2 CMCU and cellobiase live 467.05 CBU;

[0027] The purchased cellulase and β-glucosidase can be mixed according to the volume ratio of 1:4~6 to make a c...

Embodiment 2

[0042] A kind of method of extracting high-purity fucoidan sulfate ester from brown algae of the present invention, carries out according to following steps successively:

[0043] (1) Wash the fresh kelp to remove impurities such as silt, salt and mannitol on the surface, dry it in a 50°C oven, grind it into powder and pass it through a 60-mesh sieve to obtain kelp powder;

[0044] (2) Add a citric acid-sodium citrate buffer solution with a pH of 4.8 into 40 g of kelp powder, and stir while adding to obtain solution I. The mass ratio of the kelp powder to the citric acid-sodium citrate buffer solution is 1 g: 15ml;

[0045] (3) Warm up solution I to 50°C, add compound enzyme for enzymolysis for 1.5 hours to obtain solution II, the amount of compound enzyme added is filter paper enzyme activity 27.23 FPU, endocellulase activity 39.36 CMCU and cellobiase live 373.64 CBU;

[0046] The source of compound enzyme is with embodiment 1;

[0047] (4) Warm up solution II to 100°C, co...

Embodiment 3

[0056] A kind of method of extracting high-purity fucoidan sulfate ester from brown algae of the present invention, carries out according to following steps successively:

[0057] (1) Wash the fresh kelp to remove impurities such as silt, salt and mannitol on the surface, dry it in a 50°C oven, grind it into powder and pass it through a 60-mesh sieve to obtain kelp powder;

[0058] (2) Add citric acid-sodium citrate buffer solution with a pH of 4.8 into 100 g of kelp powder, and stir while adding to obtain solution I. The mass ratio of the kelp powder to the citric acid-sodium citrate buffer solution is 1 g: 17ml;

[0059] (3) Heat solution I to 50°C, add compound enzyme for enzymolysis for 1.5 hours to obtain solution II, the amount of compound enzyme added is filter paper enzyme activity 68.3 FPU, endocellulase activity 98.4 CMCU and cellobiase live 934.1 CBU;

[0060] The source of compound enzyme is with embodiment 1;

[0061] (4) Warm up solution II to 95°C and perform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com