Metal composite molecular sieve material for adsorption-catalytic oxidation of VOCs and preparation method and application thereof

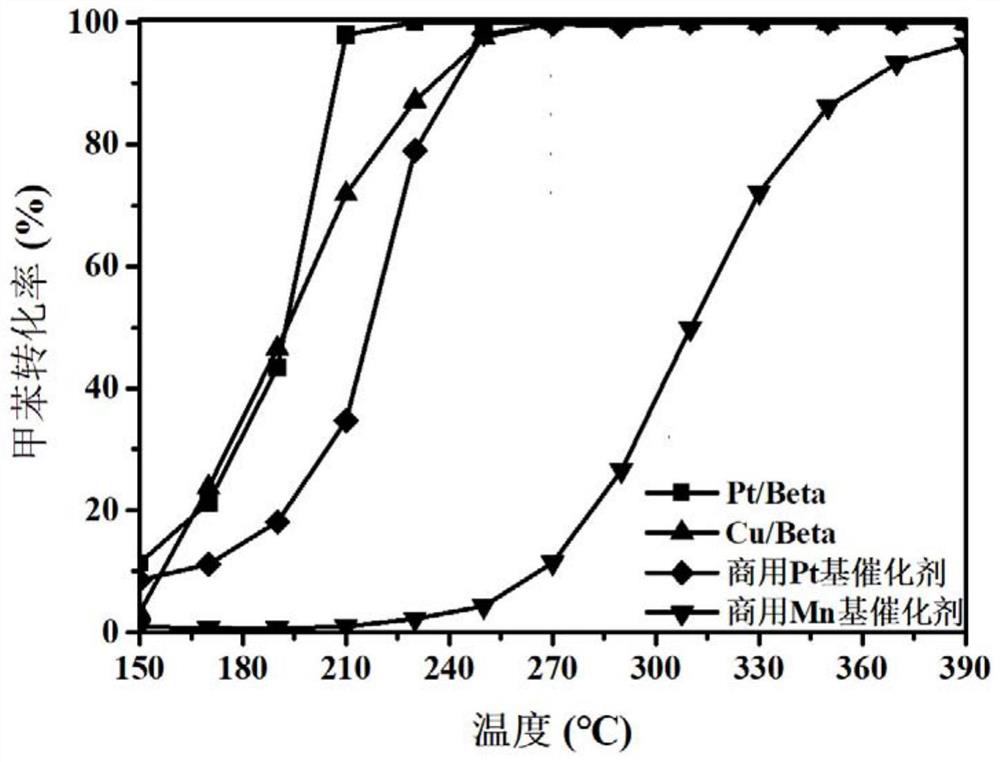

A composite molecular sieve and metal composite technology, applied in catalyst activation/preparation, separation methods, molecular sieve catalysts, etc., can solve the problems of high investment, operation and maintenance costs, high price, and narrow exhaust gas temperature range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Preparation of Beta molecular sieve:

[0043] Slowly add 22mL of tetraethylammonium hydroxide into 25mL of ethyl orthosilicate, heat and stir in a constant temperature magnetic stirrer at 60°C for 2h, then add 0.23g of sodium metaaluminate dissolved in water dropwise to form a mixed The solution was stirred at room temperature for 3 hours, then transferred to the liner of the polytetrafluoroethylene reactor, and finally put the liner of the polytetrafluoroethylene reactor into the autoclave, and reacted hydrothermally at 140°C for 3 days, and then cooled naturally. Centrifugal washing with deionized water for 5 times, vacuum freeze-drying at -30°C, and finally calcining in a muffle furnace at 550°C for 5 hours to obtain Beta molecular sieves.

Embodiment 2

[0045] Preparation of CuOx / Beta molecular sieve:

[0046] 0.22g copper acetate (Cu 2 (CH 3 COO) 4 ) mixed with 20mL of deionized water, placed in a constant temperature magnetic stirrer at 60°C and a stirring rate of 450r / min for 10 min to dissolve, add 1g of Beta molecular sieve under stirring, stir until dry, transfer to - Freeze-dry in a vacuum freeze dryer at 25°C for 24 hours, after being ground, place it in a muffle furnace for high-temperature calcination. 4h, then lowered to room temperature at a rate of 3°C / min to obtain CuOx / Beta molecular sieves.

Embodiment 3

[0048] Preparation of Pt / Beta molecular sieve:

[0049] Add 4g of Beta molecular sieve carrier into 40mL of deionized water with nitrogen gas, continuously stir vigorously at constant temperature, add 5.23mL of chloroplatinic acid solution dropwise, continue to add 5mL of methanol and 5mL of ethanol, and use a xenon lamp (Perfect light, PLS-SXE300 / 300UV) As a light source, the light intensity is 350mW / cm 2 , irradiated for 10 h under continuous stirring, centrifuged 5 times in a centrifuge with a rotating speed of 6500 r / min, and put into a vacuum freeze dryer at -25 ° C for 24 h to obtain a Pt / Beta molecular sieve catalyst prepared by photodeposition.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com