A kind of preparation method and application of water-based acrylate glue

A water-based acrylate and methyl methacrylate technology, which is applied in the field of printing and dyeing, can solve the problems of difficult to meet the high-quality requirements of glue printing, poor film resilience, and restrictions on widespread use, etc., and achieve lively, warm and comfortable touch. Chemical stability is good, highlighting the effect of aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

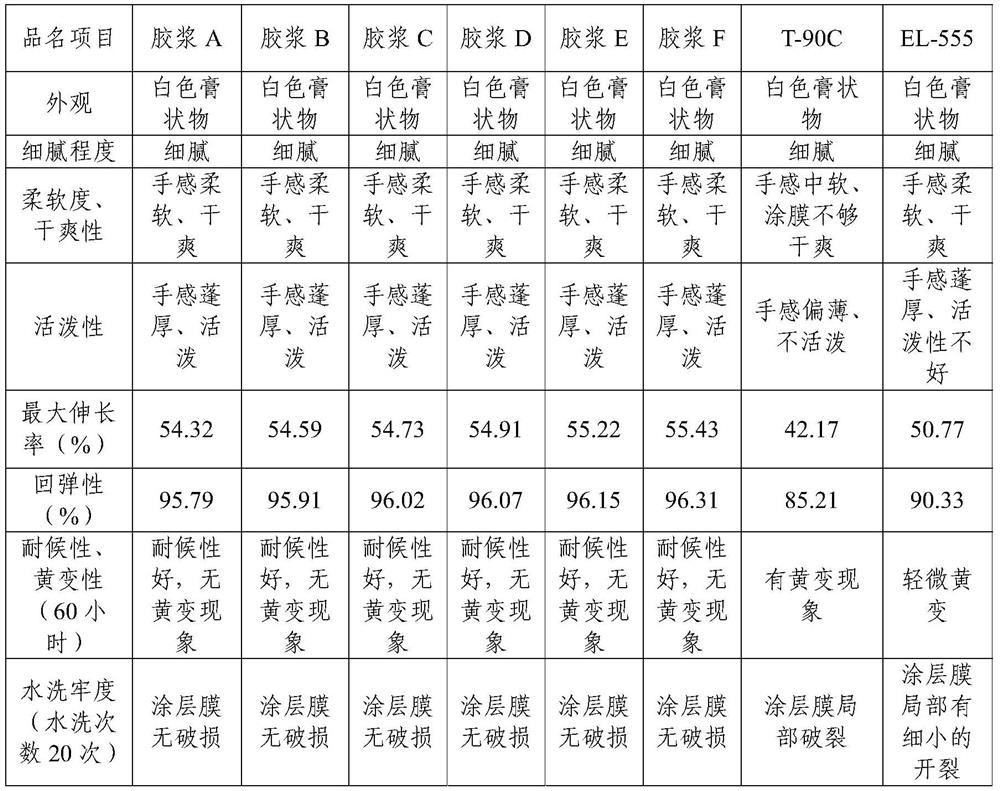

Examples

Embodiment 1

[0034] One aspect of the present invention provides a preparation method of water-based acrylate glue, the specific operations are as follows:

[0035] Step 1, 5kg of isomeric tridecyl alcohol polyoxyethylene (40) ether, 8kg of dioctyl sodium sulfosuccinate, 2kg of itaconic acid, 3.5kg of acetoacetoxyethyl methacrylate, hydroxymethacrylate Ethyl ester 0.5kg, ethyl acrylate 180kg, methyl methacrylate 4kg, styrene 5kg, isocyanate ethyl acrylate 1kg, acrylic modified reactive slip agent 1kg, deionized water 100kg, fully stirred at 100r / min for 40min, emulsification Pre-emulsion A is obtained later;

[0036] Step 2, 1kg of isomeric tridecyl alcohol polyoxyethylene (40) ether, 1kg of dioctyl sodium sulfosuccinate, 24kg of methyl methacrylate, 23kg of styrene, 0.5kg of isocyanate ethyl acrylate, acrylic acid modification Reactive slip agent 0.5kg, deionized water 29kg, fully stirred at 100r / min for 40min, after emulsification, pre-emulsion B was obtained;

[0037] Step 3, 1.2kg of...

Embodiment 2

[0044] One aspect of the present invention provides a preparation method of water-based acrylate glue, the specific operations are as follows:

[0045] Step 1, 5.2kg of isomeric tridecyl alcohol polyoxyethylene (40) ether, 8.4kg of dioctyl sodium sulfosuccinate, 2.2kg of itaconic acid, 3.7kg of acetoacetoxyethyl methacrylate, methyl methacrylate Hydroxyethyl acrylate 0.6kg, ethyl acrylate 181kg, methyl methacrylate 4.4kg, styrene 5.4kg, isocyanate ethyl acrylate 1.05kg, acrylic modified reactive slip agent 1.1kg, deionized water 102kg, 100r / min fully stirred for 40min, after emulsification, pre-emulsion A was obtained;

[0046] Step 2, 1.2kg of isomeric tridecyl alcohol polyoxyethylene (40) ether, 1.1kg of dioctyl sodium sulfosuccinate, 24.4kg of methyl methacrylate, 23.4kg of styrene, 0.55kg of isocyanate ethyl acrylate , 0.6kg of acrylic modified reactive slip agent, 31kg of deionized water, fully stirred at 100r / min for 40min, and pre-emulsion B was obtained after emulsif...

Embodiment 3

[0054] One aspect of the present invention provides a preparation method of water-based acrylate glue, the specific operations are as follows:

[0055] Step 1, 5.4kg of isomeric tridecyl alcohol polyoxyethylene (40) ether, 8.8kg of dioctyl sodium sulfosuccinate, 2.4kg of itaconic acid, 3.9kg of acetoacetoxyethyl methacrylate, methyl methacrylate Hydroxyethyl acrylate 0.7kg, ethyl acrylate 182kg, methyl methacrylate 4.8kg, styrene 5.8kg, isocyanate ethyl acrylate 1.1kg, acrylic modified reactive slip agent 1.2kg, deionized water 104kg, 100r / min fully stirred for 30min, pre-emulsion A was obtained after emulsification;

[0056] Step 2, isomerized tridecyl alcohol polyoxyethylene (40) ether 1.4kg, dioctyl sodium sulfosuccinate 1.2kg, methyl methacrylate 24.8kg, styrene 23.8kg, isocyanate ethyl acrylate 0.6kg , 0.7kg of acrylic modified reactive slip agent, 33kg of deionized water, fully stirred at 100r / min for 30min, and pre-emulsion B was obtained after emulsification;

[005...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com