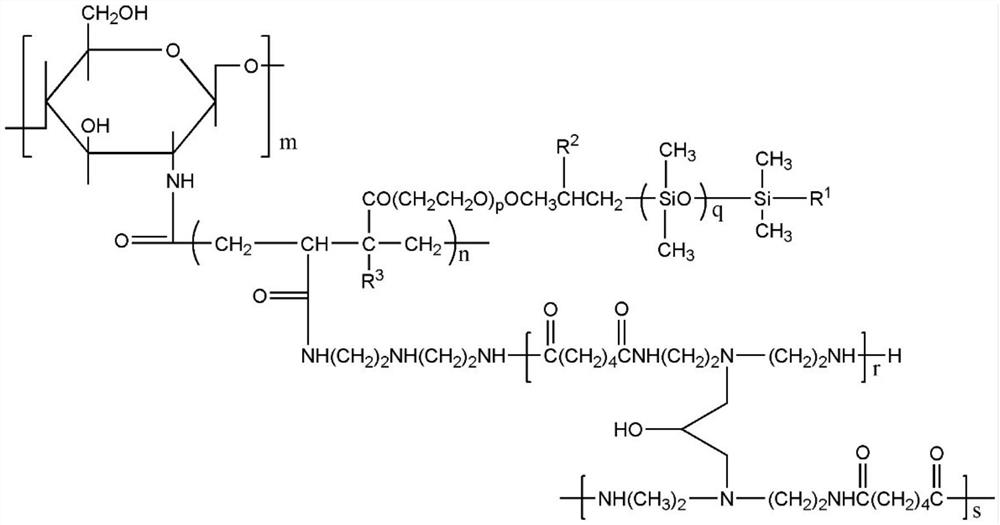

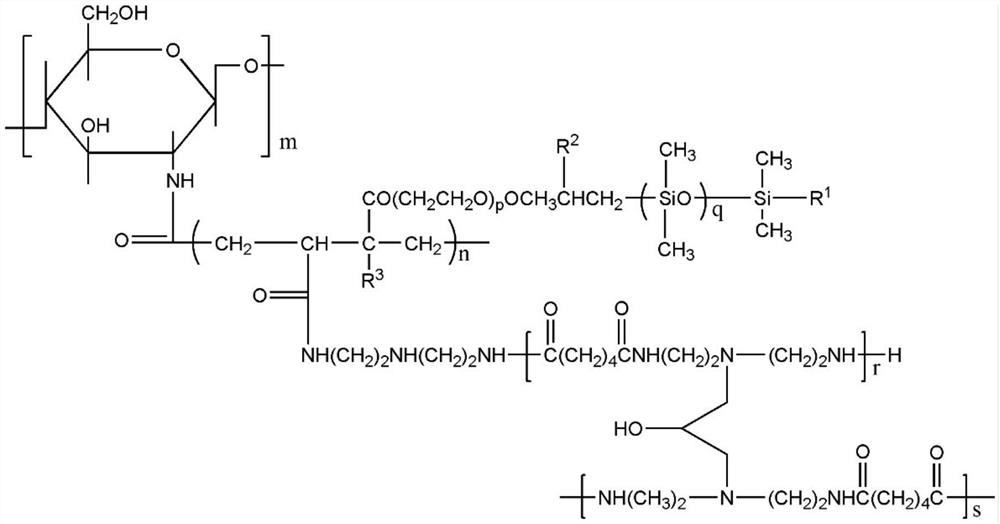

Cylinder sticking agent for household paper machine and preparation method of cylinder sticking agent

A technology of household paper and cylinder sticking agent, which is applied in the field of sticking agent for papermaking, can solve the problems of hard film layer, insufficient re-wetting, and poor film-forming ability, and achieves good film-forming and good re-wetting. , the effect of feeling good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

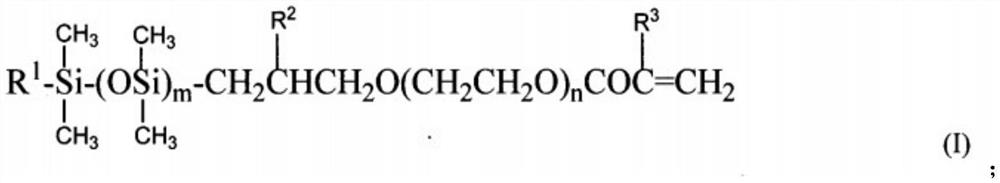

Method used

Image

Examples

Embodiment 1

[0054] The chitosan (degree of deacetylation is 85%) that takes by weighing 100g joins 500ml mass fraction and is in the acetic acid solution of 2%, dissolves 1 hour under stirring, forms homogeneous solution; 8g maleic anhydride is dissolved in the 50ml acetone, After stirring evenly, add it into the homogeneous solution, react at room temperature for 14 hours, purify the product with acetone, and dry it in a vacuum constant temperature oven to obtain the modified chitosan. Add 200g of deionized water and 40g of the modified chitosan prepared in front of the reaction flask, adjust the pH at 5.5 with 2% acetic acid with a mass fraction, add 0.05g of chelating agent EDTA-2Na, 1g of chain transfer agent sodium hypophosphite , into N 2 Deoxygenation for 30 minutes; then raise the temperature to 65-80°C, add dropwise 8g of hydrophilic silicone monomer and 20g of 0.4% initiator ammonium persulfate solution at the same time, and keep the reaction at 85°C for 1 hour after adding drop...

Embodiment 2

[0057] Add 6.8 parts of diethylenetriamine and 8.5 parts of adipic acid into the reaction flask, stir evenly, raise the temperature to 150°C, continuously distill the water generated by the reaction, and continue to heat up to 165°C after reacting for 1 hour, and continue the reaction for 4 hour, then add 6 parts of water to terminate the reaction, and finally add 7 parts of dilution water to obtain a polyamide polyamine polymer with a solid content of 50%. Add 23.4 parts of polyamide polyamine polymer and 8 parts of maleic anhydride acylated chitosan grafted silicone copolymer solution into the reaction flask, mix well, add 17 parts of water to adjust the solid content, and then drop 1.5 Parts of epichlorohydrin, heated up to 60°C and reacted for 2-2.5 hours, after reacting at 60°C for 1.5 hours, take samples to measure the viscosity every 15 minutes, add water to terminate the reaction when the viscosity of the solution reaches 250-400mPa.s, and obtain the reactant . Cool t...

Embodiment 3

[0059] Add 10 parts of triethylenetetramine and 10 parts of adipic acid into the reaction flask, stir evenly, raise the temperature to 150°C, and continuously distill off the water generated by the reaction. After reacting for 1 hour, continue to heat up to 175°C, and continue the reaction for 2 hour, then add 5 parts of water to terminate the reaction, and finally add 10 parts of dilution water to obtain a polyamide polyamine polymer with a solid content of 50%. Add 25 parts of polyamide polyamine polymer and 4 parts of maleic anhydride acylated chitosan grafted silicone copolymer solution into the reaction flask, mix well, add 17 parts of water to adjust the solid content, and then drop 1.4 Parts of epichlorohydrin, heated up to 65°C and reacted for 2-2.5 hours, after reacting at 65°C for 1.5 hours, take samples to measure the viscosity every 15 minutes, add water to terminate the reaction when the viscosity of the solution reaches 300-450mPa.s, and obtain the reactant . Co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com