Preparation method of adsorbent for CO pressure swing adsorption

A pressure swing adsorption and adsorbent technology, which is applied in the chemical industry and can solve the problems of low mechanical strength and low adsorption efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Weigh 1gX molecular sieve, add 17g of sodium aluminate solution with mass concentration of 40%, and 20g of tetrapropylammonium bromide solution with mass concentration of 6%, then crystallize at 120°C for 5h, cool, wash and dry. The first modified carrier.

[0038] Afterwards, the first modified carrier is placed in water so that the mass ratio of the first modified carrier to water is 3:7, and then ethylenediamine is added so that the mass ratio of water to ethylenediamine is 5:1. Then, it was treated in gas-solid phase at 160° C. for 15 hours, washed with water and dried to obtain a second modified carrier.

[0039] Weigh 10 g of the second modified carrier, mix it with 3 g of cuprous chloride and an appropriate amount of water, mix it evenly, extrude it, leave it to stand and then dry it to obtain an adsorbent precursor.

[0040] The obtained adsorbent precursor was placed in a muffle furnace, calcined at 200°C for 5 hours, then soaked in a 5% hydrochloric acid solu...

Embodiment 2

[0043] Weigh 1g SAPO-34 molecular sieve, add 25g mass concentration of 40% aluminum sulfate solution, 15g mass concentration of 5% n-propylamine solution and 12g mass concentration of 5% phosphoric acid solution, then crystallize at 110 ° C for 4h, after cooling, washing with water and drying to obtain the first modified carrier.

[0044]Afterwards, the first modified carrier was placed in water so that the mass ratio of the first modified carrier to water was 3:7, and then n-butylamine was added to make the mass ratio of water to ethylenediamine 6:1. Then, it was treated in gas-solid phase at 150° C. for 12 hours, washed with water and dried to obtain a second modified carrier.

[0045] Weigh 10 g of the second modified carrier, mix it with 3 g of cuprous chloride and an appropriate amount of water, mix it evenly, extrude it, leave it to stand and then dry it to obtain an adsorbent precursor.

[0046] The prepared adsorbent precursor was placed in a muffle furnace, calcined ...

Embodiment 3

[0049] Adsorbent C was prepared in the same manner as in Example 1, except that aluminum acetate was used instead of sodium aluminate in Example 1.

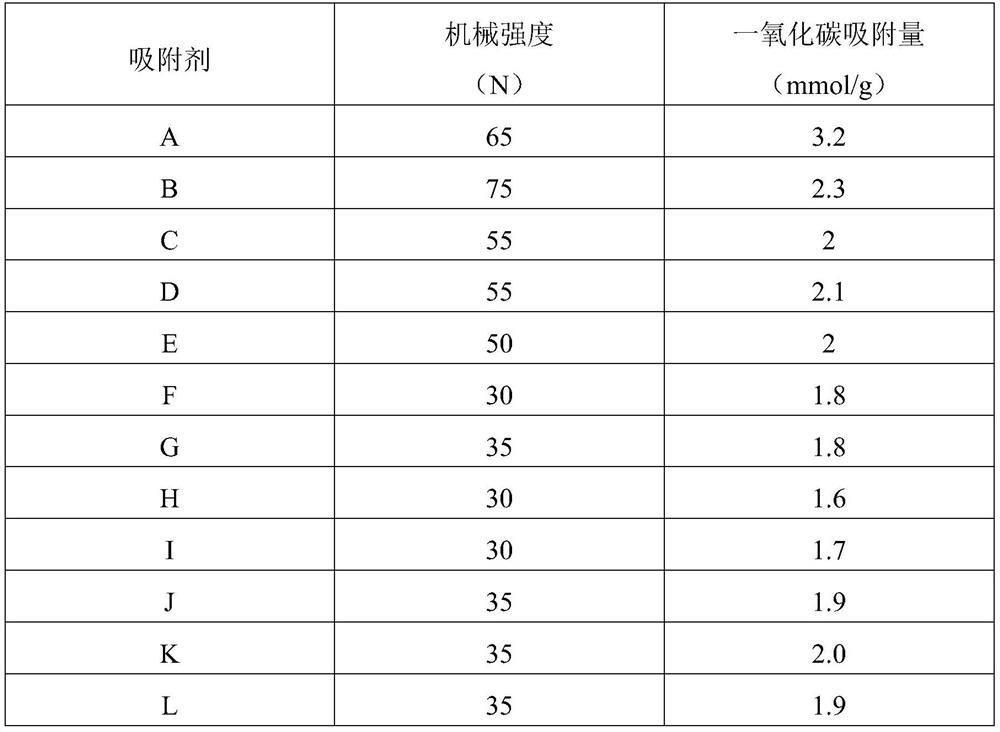

[0050] The mechanical strength of the adsorbent C and the carbon monoxide adsorption capacity at 18° C. and a carbon monoxide pressure of 760 mmHg were tested, and the results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com