Sleeve grouting material for prefabricated part and preparation method of material

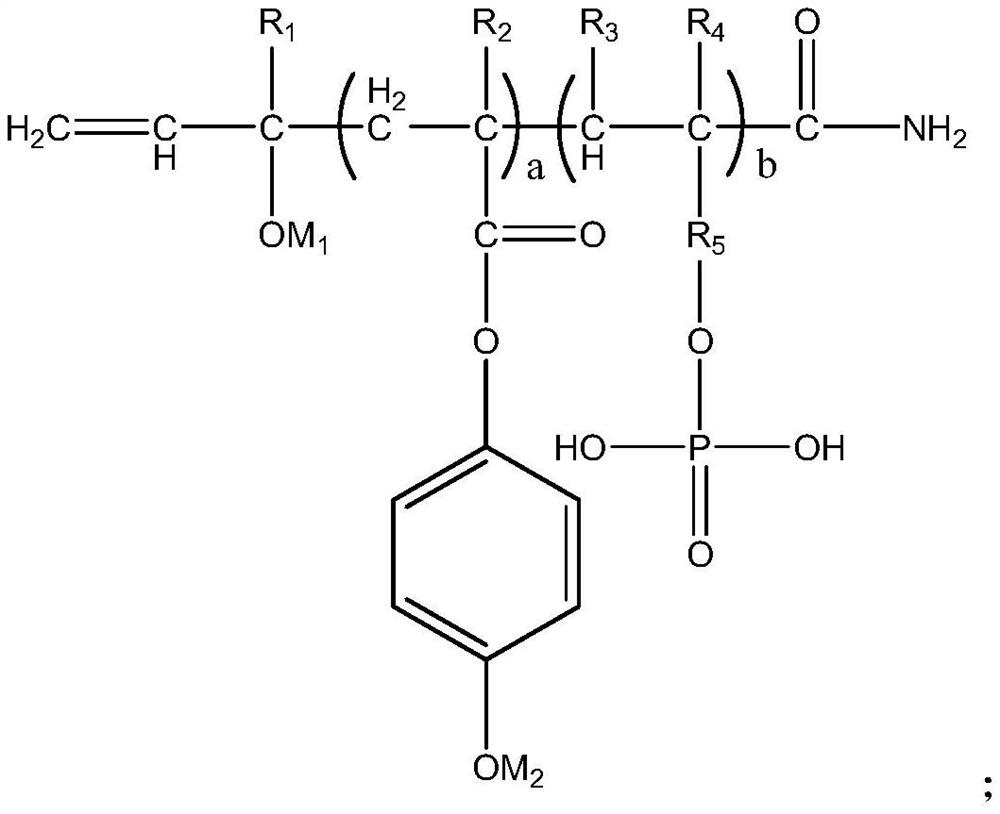

A sleeve grouting and prefabricated component technology, applied in the field of prefabricated component building materials, can solve problems such as poor fluidity, and achieve the effects of improving fluidity, stable performance and reducing brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

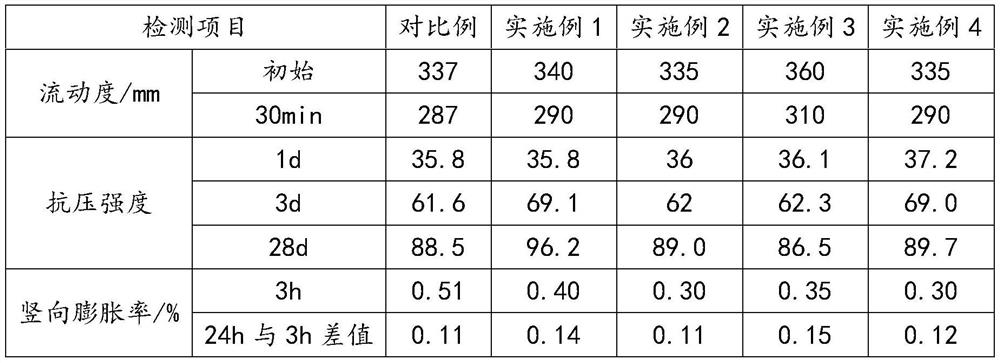

Examples

Embodiment 1

[0033] In parts by weight, weigh 63 parts of machine-made sand and 7 parts of molybdenum tailings sand, and stir in a mortar mixer at a medium speed for 5 minutes to obtain mixed sand. Add 1 part of water-soluble polyether polyurethane, 1 part of hydroxyethyl methylcellulose ether, and 1 part of methyl methacrylate-butadiene-styrene polymer into the reaction kettle, add water, and adjust the temperature to 20°C , stirred for 20 minutes to make it dissolve, then added mixed sand and 20 parts of 100-mesh beer bottle ground powder under stirring, continued to stir for 20 minutes, then added 1 part of polycarboxylate superplasticizer and 70 parts of cement, and stirred evenly for 20 minutes. The rest of the water is added to obtain the sleeve grouting material for the prefabricated component.

Embodiment 2

[0035] In parts by weight, weigh 68 parts of machine-made sand and 12 parts of molybdenum tailings sand, and stir in a mortar mixer at a medium speed for 4 minutes to obtain mixed sand. Add 2 parts of water-soluble polyester polyurethane, 2 parts of hydroxypropyl methylcellulose ether, and 2 parts of acrylonitrile-butadiene-styrene polymer into the reaction kettle, add water, adjust the temperature to 30°C, and stir for 15 minutes , to make it dissolve, then under stirring, add mixed sand and 25 parts of 150 mesh waste glass ground powder, continue stirring for 25 minutes, then add 3 parts of polycarboxylate superplasticizer and 80 parts of cement, stir evenly for 15 minutes, add the rest water, that is, the sleeve grouting material for the prefabricated component.

Embodiment 3

[0037]In parts by weight, weigh 68 parts of machine-made sand and 12 parts of molybdenum tailings sand, and stir in a mortar mixer at a medium speed for 3 minutes to obtain mixed sand. Add 2 parts of water-soluble polyester polyurethane, 2 parts of hydroxypropyl methylcellulose ether, and 2 parts of acrylonitrile-butadiene-styrene polymer into the reaction kettle, add water, adjust the temperature to 40°C, and stir for 10 minutes , to make it dissolve, then under stirring, add 25 parts of mixed sand and 150 mesh waste glass ground powder, continue stirring for 30 minutes, then add 3 parts of polycarboxylate superplasticizer and 80 parts of cement, stir evenly for 20 minutes, add the rest water, that is, the sleeve grouting material for the prefabricated component.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water reduction rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com