Cleaning agent and preparation method and application thereof

A cleaning agent and builder technology, which can be applied to cleaning methods and utensils, cleaning methods using liquids, detergent compounding agents, etc., and can solve the problems of high processing costs, long processing time, and complicated processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

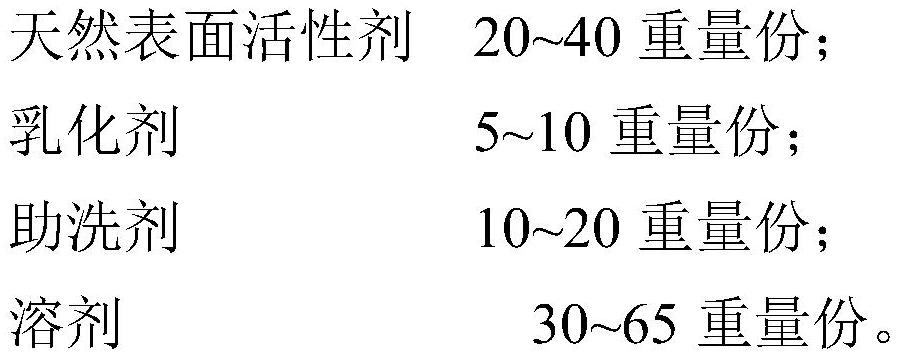

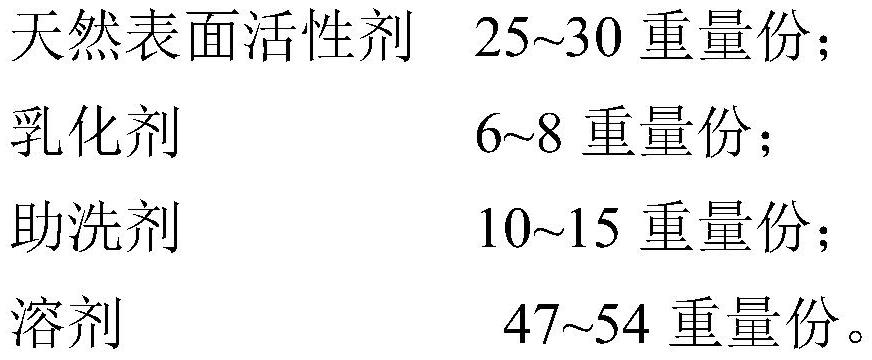

[0062] Preparation of cleaning agent: Take 20 parts of natural surfactant D-limonene, 5 parts of emulsifier AEO-7, 10 parts of builder sodium carbonate, and 65 parts of tap water in a beaker, mechanically stir at 300rpm, stir for 30min, mix well, Prepared as a cleaning agent.

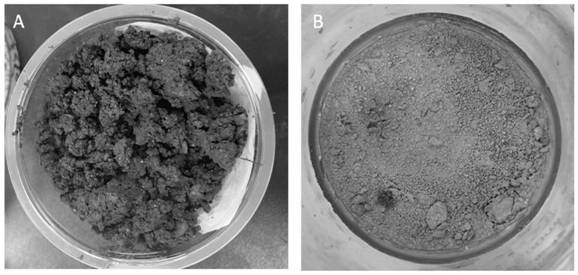

[0063] Cleaning of floor sludge: Mix floor sludge and water at a mass ratio of 1:2, and mechanically stir evenly at room temperature at a speed of 300rpm for 10 minutes. After stirring evenly, add cleaning agent in an amount of 1% of the mass of the ground sludge. After adding the cleaning agent, continue stirring for 30min. After cleaning, let it stand at room temperature for 10 minutes, collect the supernatant oil, and use a centrifuge to centrifuge the remaining muddy water mixture at 3000 rpm for 5 minutes. After the centrifugation is completed, the upper oil slick and the middle water layer are collected, the lower layer is removed and cleaned, and the sludge falls to the ground. After drying, th...

Embodiment 2

[0065] Preparation of cleaning agent: Take 25 parts of natural surfactant alkyl sugar anhydride, 6 parts of emulsifier AEO-7, 15 parts of builder sodium silicate, 54 parts of tap water in a beaker, mechanically stir at 300rpm, stir for 30min, mix Uniform, formulated as a cleaning agent.

[0066] Cleaning of floor sludge: mix floor sludge and water at a mass ratio of 1:2, and mechanically stir evenly at room temperature at a speed of 400rpm for 10 minutes. After stirring evenly, add cleaning agent in an amount of 1.5% of the mass of the ground sludge. After adding the cleaning agent, continue to stir for 40min. After cleaning, let it stand at room temperature for 20 minutes, collect the supernatant oil, and use a centrifuge to centrifuge the remaining muddy water mixture at 3000 rpm for 10 minutes. After the centrifugation is completed, the upper layer of slick oil and the middle water layer are collected, the lower layer is taken off and cleaned, and the oily sludge falls to...

Embodiment 3

[0068] Preparation of cleaning agent: Take 30 parts of natural surfactant tea saponin, 8 parts of emulsifier AEO-9, 10 parts of builder sodium silicate, 5 parts of sodium tripolyphosphate, 47 parts of tap water in a beaker, mechanically stir, 300rpm, stir for 30min, mix evenly, and make floor sludge cleaning agent.

[0069] Cleaning of floor sludge: mix floor sludge and water at a mass ratio of 1:2, and mechanically stir evenly at room temperature with a speed of 400rpm and a stirring time of 20min. After stirring evenly, add cleaning agent in an amount of 2% of the mass of the ground sludge. After adding the cleaning agent, continue stirring for 50min. After cleaning, let it stand at room temperature for 30 minutes, collect the supernatant oil, and use a centrifuge to centrifuge the remaining muddy water mixture at 3000 rpm for 10 minutes. After the centrifugation is completed, the upper oil slick and the middle water layer are collected, the lower layer is taken off and cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com