Preparation method of low-fat and low-sugar soybean protein ice cream

A technology of soybean protein and ice cream, which is applied in the direction of microsphere preparation, protein-containing food ingredients, bacteria used in food preparation, etc., can solve the problems of low-fat product quality loss, etc., and achieve reduced fat content, good foamability, Enhanced health-promoting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A preparation method of low-fat and low-sugar soybean protein ice cream, comprising the following steps:

[0026] (1) Enzymatic soy protein isolate (SPI) treatment: the degree of hydrolysis was prepared by hydrolyzing 16% (w / v) SPI with 2.4 L of commercially available alkaline protease in deionized water at pH 8.0 and 5.5 °C for a certain time 1% Hydrolyzed Soy Protein (SPH).

[0027] (2) Thermal shearing treatment: Xanthan gum (XG) is mixed into the soybean protein hydrolyzate obtained in step 1, mixed at a ratio of 100:0 (w / w), and then adjusted to 10% (w / w) Add deionized water to the SPH / XG mixed solution. Stir the SPH / XG mixed system and incubate in a water bath at 90 °C for 20 min, resulting in complete denaturation of the protein and swelling of the XG. The SPH / XG microparticle fat substitute was obtained by high-speed shearing on an IKA-T25 homogenizer at room temperature (about 25 °C) at 8000 rpm.

[0028] (3) Combination of prebiotics and probiotics: Lactoba...

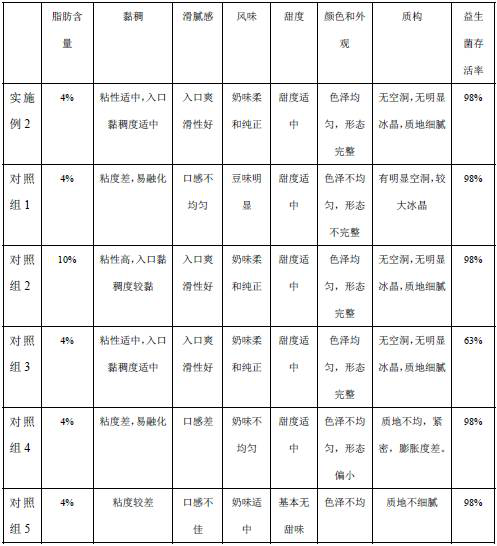

Embodiment 2

[0038] A preparation method of low-fat and low-sugar soybean protein ice cream, comprising the following steps:

[0039] (1) Enzymatic soy protein isolate (SPI) treatment: the degree of hydrolysis was prepared by hydrolyzing 16% (w / v) SPI with 2.4 L of commercially available alkaline protease in deionized water at pH 8.0 and 5.5 °C for a certain time 5% hydrolyzed soy protein (SPH).

[0040] (2) Thermal shearing treatment: Xanthan gum (XG) is mixed into the soybean protein hydrolyzate obtained in step 1, mixed in a ratio of 96:4 (w / w), and then adjusted to 10% (w / w) SPH / XG mixed solution was added deionized water. Stir the SPH / XG mixed system and incubate in a water bath at 90 °C for 20 min, resulting in complete denaturation of the protein and swelling of the XG. The SPH / XG microparticle fat substitute was obtained by high-speed shearing on an IKA-T25 homogenizer at room temperature (about 25°C) at 8000 rpm.

[0041] (3) Combination of prebiotics and probiotics: Lactobaci...

Embodiment 3

[0051] A preparation method of low-fat and low-sugar soybean protein ice cream, comprising the following steps:

[0052] (1) Enzymatic soy protein isolate (SPI) treatment: the degree of hydrolysis was prepared by hydrolyzing 16% (w / v) SPI with 2.4 L of commercially available alkaline protease in deionized water at pH 8.0 and 5.5 °C for a certain time 8% Hydrolyzed Soy Protein (SPH).

[0053] (2) Thermal shearing treatment: Xanthan gum (XG) is mixed into the soybean protein hydrolyzate obtained in step 1, mixed at a ratio of 92:8 (w / w), and then adjusted to 10% (w / w) Add deionized water to the SPH / XG mixed solution. Stir the SPH / XG mixed system and incubate in a 90°C water bath for 20 min, resulting in complete denaturation of the protein and swelling of the XG. SPH / XG microparticle fat substitutes were obtained by high-speed shearing on an IKA-T25 homogenizer at room temperature (approximately 25°C) at 8000 rpm.

[0054] (3) Combination of prebiotics and probiotics: Lactoba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com