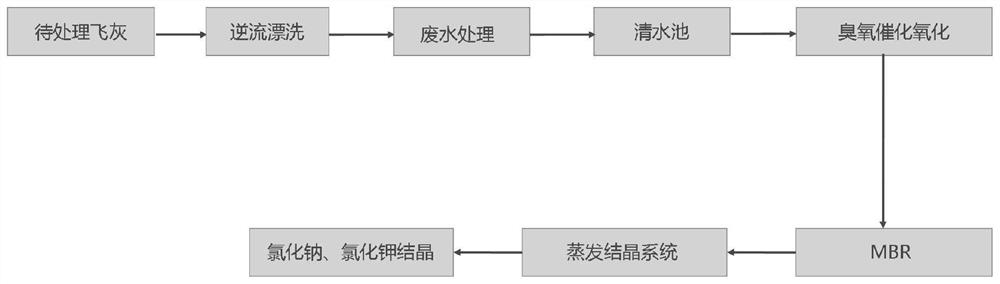

Efficient pretreatment process for household garbage incineration fly ash evaporation system

A domestic waste incineration and treatment process technology, applied in the field of solid waste recycling, can solve the problems of lack of practical application in the pretreatment section of the fly ash washing evaporator

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The core ozone purification material (catalytic material) uses activated alumina particles from raw materials sourced from high-temperature roasting, and the main preparation process is as follows:

[0038] 1 Purchase commercial activated alumina with a particle size of 10mm. The main parameters of activated alumina include: adsorption capacity greater than 20%, specific surface area greater than 260m 2 / g, the activated alumina is sieved with a 10mm sieve, and after fully sieving twice, the small-sized activated alumina particles are removed to form uniform activated alumina particles, which are soaked with clean water to remove impurities from industrial products.

[0039] 2 Immerse the sieved uniform activated alumina particles with a volume of 2m 3 In a stainless steel container, 2 mol / L manganese sulfate (MnSO 4 ) for soaking and stirring, so that the manganese sulfate is evenly distributed in the pores of activated alumina, and the soaking and stirring time is 48...

Embodiment 2

[0043] For the effluent of a fly ash washing wastewater treatment pool in Zhejiang, the treatment scale is 250 tons / day, TOC=26.4 mg / L, the concentration of ozone directly added is 36mg / L (uncatalyzed), and the effluent TOC=21.2mg / L , Ozone catalytic oxidation water COD = 13.8mg / L, greatly improving the efficiency of ozone oxidation treatment.

Embodiment 3

[0045]For the effluent of a fly ash washing wastewater treatment tank in Zhejiang, the treatment scale is 250 tons per day, the turbidity of the wastewater washing and cleaning tank effluent = 46NTU, after the "ozone catalytic oxidation + MBR" system treatment, the design flow rate of the submerged ultrafiltration is 6.8L / (m2h), effluent turbidity = 0.1NTU, crystal salt impurities are reduced from 0.95% to 0.45%, greatly improving the quality of crystal salt.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com