Flame-retardant conductive adhesive for electronic packaging and preparation method thereof

A technology for electronic packaging and conductive adhesives, applied in conductive adhesives, adhesives, epoxy resin adhesives, etc., can solve problems such as inability to achieve permanent modification, prevent excessive contact from affecting bonding performance, not easily oxidized, and prepare simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

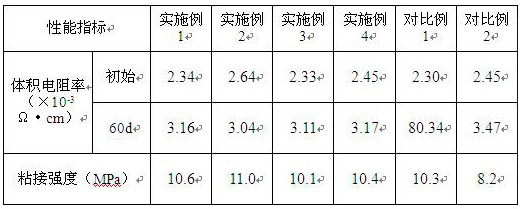

Examples

Embodiment 1

[0031] (1) 30 parts by weight of ultra-fine spherical copper powder with a particle size of 2-5 μm is ultrasonically cleaned to remove impurities, and then 3 parts by weight of silane coupling agent is added to 67 parts by weight of absolute ethanol, and 2 parts by weight of carbon airgel is added , stirring at a speed of 500 rpm for 15 minutes, then standing, filtering, and drying naturally to obtain carbon airgel-loaded copper powder;

[0032] (2) Stir and disperse the silica airgel, the flame retardant trimethyl phosphate, and the curing agent methyl hexahydrophthalic anhydride at a mass ratio of 1:3:1, so that the silica airgel can fully absorb the flame retardant Agent, curing agent, obtain the silica airgel of loading flame retardant and curing agent;

[0033] (3) Add 5 parts by weight of the carbon airgel-loaded copper powder prepared in step (1) to 46 parts by weight of the base glue bisphenol A epoxy resin, mix and stir for 1 hour, let stand at room temperature for 24...

Embodiment 2

[0035] (1) 35 parts by weight of ultra-fine spherical copper powder with a particle size of 2-5 μm is ultrasonically cleaned to remove impurities, and then 4 parts by weight of silane coupling agent is added to 60 parts by weight of absolute ethanol, and 2 parts by weight of carbon airgel is added , stirred at a speed of 800rpm for 20min, then left to stand, filtered, and dried naturally to obtain carbon airgel-loaded copper powder;

[0036] (2) Stir and disperse the silica airgel, the flame retardant triethylphosphonate, and the curing agent methyl hexahydrophthalic anhydride at a mass ratio of 1:3:1, so that the silica airgel can fully absorb and resist Flame retardant, curing agent, obtain the silica airgel of loading flame retardant and curing agent;

[0037](3) Add 8 parts by weight of the carbon airgel-loaded copper powder prepared in step (1) to 52 parts by weight of the base glue bisphenol A epoxy resin, mix and stir for 1.5 hours, let stand at room temperature for 24 ...

Embodiment 3

[0039] (1) 40 parts by weight of ultra-fine spherical copper powder with a particle size of 2-5 μm is ultrasonically cleaned to remove impurities, and then 5 parts by weight of silane coupling agent is added to 67 parts by weight of absolute ethanol, and 3 parts by weight of carbon airgel is added , stirred at a speed of 800rpm for 20min, then left to stand, filtered, and dried naturally to obtain carbon airgel-loaded copper powder;

[0040] (2) Stir and disperse the silica airgel, the flame retardant hexamethylphosphazene, and the curing agent methyl hexahydrophthalic anhydride at a mass ratio of 1:3:1, so that the silica airgel can fully absorb the flame retardant Agent, curing agent, obtain the silica airgel of loading flame retardant and curing agent;

[0041] (3) Add 10 parts by weight of the carbon airgel-loaded copper powder prepared in step (1) to 56 parts by weight of the base glue bisphenol A epoxy resin, mix and stir for 1.5 hours, and let stand at room temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com