Silicone structural adhesive for insulating glass and preparation method thereof

A technology for structural adhesives and glass, applied in adhesives, non-polymer adhesive additives, adhesive additives, etc., can solve the problems of slow curing rate of structural adhesives, easy agglomeration of graphene, increased manufacturing costs, etc., to improve strength and High temperature strength retention rate, low water vapor permeability, and the effect of improving tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

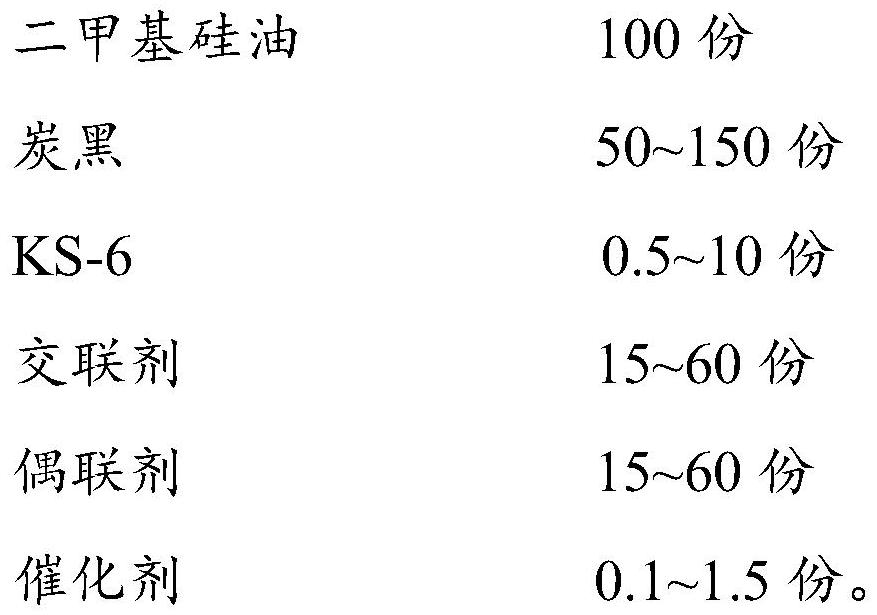

[0074] A component (parts by weight):

[0075] Take 100 parts of hydroxyl-terminated polydimethylsiloxane with a viscosity of 20,000 mPa·s and 10 parts of dimethicone with a viscosity of 400 mPa·s and add them to the kneader to stir and disperse. After 5 minutes, 100 parts of 100 nm The nanometer active calcium carbonate of particle size is added therein to make the glue (ie, the hydroxyl-terminated polydimethylsiloxane and dimethicone) completely cover the powder to form a self-leveling base material, and the reaction temperature is controlled to be 80° C., stirring and mixing 1h to obtain component A, which is used after grinding.

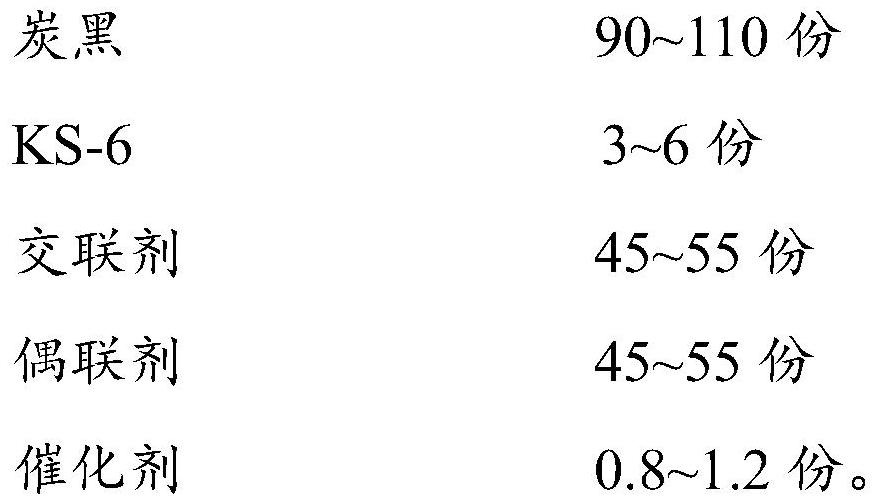

[0076] Component B (parts by weight):

[0077] Add 100 parts of dimethyl silicone oil with a viscosity of 1000 mPa·s, 4 parts of artificial graphite KS-6, and 96 parts of carbon black into the planetary machine vacuum (vacuum degree of -0.095MPa) and stir, and keep the temperature at 100 ° C for 30 minutes, and then Add 50 parts of composite cr...

Embodiment 2

[0080] A component (parts by weight):

[0081] Take 100 parts of hydroxyl-terminated polydimethylsiloxane with a viscosity of 20,000 mPa·s and 10 parts of dimethicone with a viscosity of 400 mPa·s and add them to the kneader to stir and disperse. After 5 minutes, 100 parts of 200 nm Nanometer active calcium carbonate with particle size was added to make the glue completely cover the powder to form a self-leveling base material.

[0082] Component B (parts by weight):

[0083] Add 100 parts of dimethyl silicone oil with a viscosity of 1000 mPa·s, 4 parts of KS-6, and 96 parts of carbon black to the planetary machine vacuum (vacuum degree of -0.095MPa) and stir, and keep the temperature at 100 ° C for 30 minutes, and then add 50 parts of composite cross-linking agent, 50 parts of composite coupling agent and 1 part of composite catalyst, and stirred for 10 minutes at a constant 100°C under nitrogen protection to obtain component B;

[0084] Then, according to the mixing volume...

Embodiment 3

[0086] A component (parts by weight):

[0087] Take 100 parts of hydroxyl-terminated polydimethylsiloxane with a viscosity of 20,000 mPa·s and 10 parts of dimethicone with a viscosity of 400 mPa·s and add them to the kneader to stir and disperse. After 5 minutes, 50 parts of 100 nm , 50 parts of nanometer active calcium carbonate with a particle size of 200nm are added to make the glue completely cover the powder to form a self-leveling base material, control the reaction temperature to 80 ° C, stir and mix for 1h to obtain the A component, and grind it for later use.

[0088] Component B (parts by weight):

[0089] Add 100 parts of dimethyl silicone oil with a viscosity of 1000 mPa·s, 4 parts of KS-6, and 96 parts of carbon black to the planetary machine vacuum (vacuum degree of -0.095MPa) and stir, and keep the temperature at 100 ° C for 30 minutes, and then add 50 parts of composite cross-linking agent, 50 parts of composite coupling agent and 1 part of composite catalyst,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com