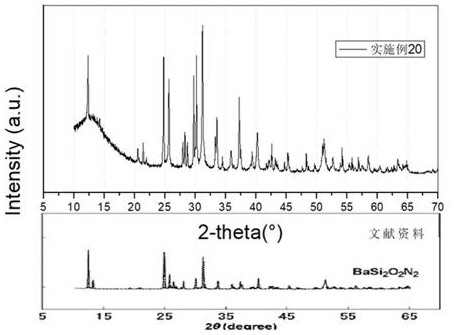

Blue fluorescent powder and preparation method thereof

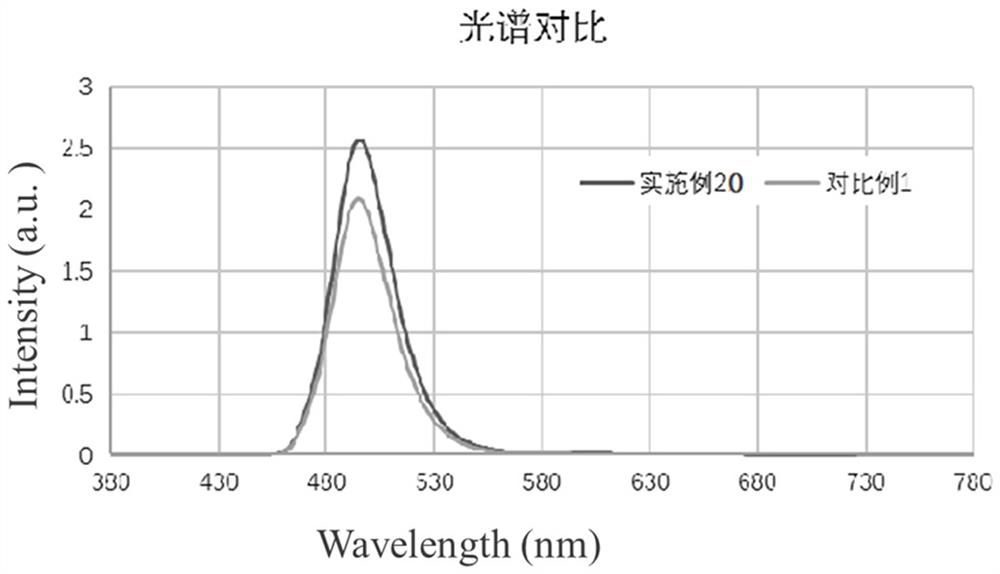

A blue phosphor and phosphor technology, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of low color rendering index of phosphor encapsulation, unfavorable industrial production, poor moisture and heat resistance, etc., so as to improve the luminous performance, Avoid heavy workload and improve uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] According to the chemical formula is Ba 0.99 Eu 0.01 Al 0.01 Si 2 o 2 N 2.01 The molar ratio of each element in the glove box was weighed Ba 3 N 2 (purity greater than 99.5%) 57.14g, SiO 2 (purity greater than 99.5%) 23.64g, Si 3 N 4 (purity greater than 99.5%) 18.40g, EuN (purity greater than 99.5%) 0.65g, AlN 0.16g and NH 4 Cl (purity greater than 99.5%) 1 g. Weigh 0.5g NaCl as a flux, put it into a ball mill jar, add alcohol, mix in a ball mill for 120 minutes, then pass the mixed raw materials through a 300-mesh nylon sieve through an ultrasonic vibrator, and pass the sieved raw materials through a spray granulator to produce 8μm balls, then put the raw material granulation balls into the molybdenum crucible, and quickly advance them into the atmosphere-protected rotary kiln with a heat preservation zone of 1300°C, where the protective atmosphere is H 2 content is 80% H 2 -N 2 Mixed gas, keep warm for 150 minutes, then quickly push out the furnace body,...

Embodiment 2-9

[0040] According to the synthetic chemical formula is Ba 0.99 Eu 0.01 Al 0.01 Si 2 o 2 N 2.01 , change the parameters in the preparation process (see Table 1 for details), and other operations are carried out according to the method of Example 1, and the obtained phosphor is characterized, and the results are shown in Table 1.

[0041] Table 1:

[0042]

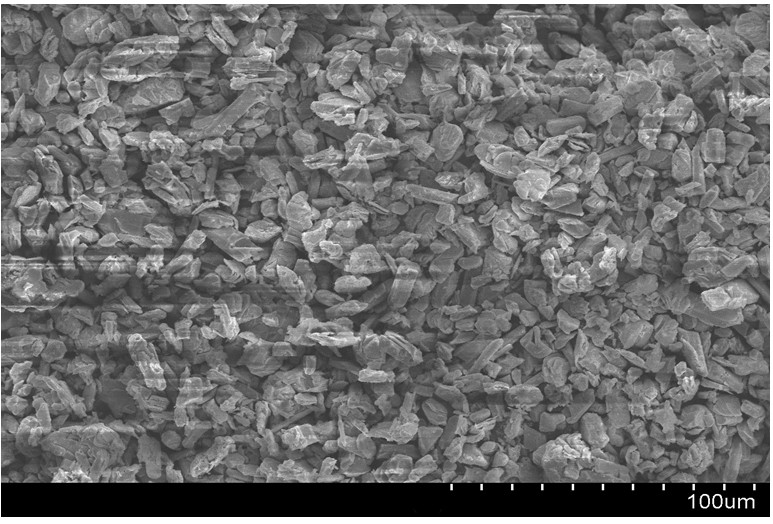

[0043] It can be seen from Table 1 that after adopting the ultrasonic sieving and spray granulation process, the particle distribution of the product is obviously more concentrated, the brightness is higher, and the luminescence is more uniform. With the increase of the holding time, the product brightness first increases and then As the temperature in the high temperature zone increases, the brightness of the product also increases first and then decreases. The size of the spherical particles of the raw material granulation also affects the size of the product particles.

Embodiment 10

[0045] According to the chemical formula is Ba 0.98 Eu 0.02 Al 0.01 Si 2 o 2 N 2.01 The molar ratio of each element in the glove box was weighed Ba 3 N 2 Mass 56.65g, SiO 2 Mass 23.68g, Si 3 N 4 Mass 18.43g, AlN mass 0.41g, EuN mass 1.3g. Weigh MgCl 2 As a flux, the mass accounts for 2% of the total mass of raw materials, put into a ball mill tank and add alcohol, mix in a ball mill for 180 minutes, then pass the mixed raw materials through a 300-mesh nylon sieve through an ultrasonic vibrator, and pass the sieved raw materials through The spray granulation machine makes 10μm balls, and then puts the raw material granulation balls into the molybdenum crucible, and quickly pushes them into the atmosphere-protected rotary kiln with a heat preservation zone of 1450°C, where the protective atmosphere is H 2 content is 80% H 2 -N 2 Mixed gas, keep warm for 150 minutes, then quickly push out the furnace body, take out the material in the molybdenum crucible and simply p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com