Method for purifying polygalacturonase by galacturonic acid magnetic nanoparticles

A technology of magnetic nanoparticles and galacturonic acid, which is applied in the direction of glycosylase, biochemical equipment and methods, enzymes, etc., can solve the problems that have not been reported, and achieve cheap methods, low juice viscosity, and loss of enzyme activity small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1, the optimization of Aspergillus flavus growth

[0036] Aspergillus flavus was obtained from the Applied Molecular Biotechnology Research Laboratory (AMBR), Punjab University, Lahore, Pakistan, on glucose-free pectin agar medium (1% NaNO 3 , 0.5% MgSO 4 .7H 2 O, 0.1% CaCl 2 , 1.0μM FeCl 3 , pH 7.2 and 2.0% agar) to keep the slope. Use about 2ml (1×10 10 / ml spores) of Aspergillus flavus liquid culture was inoculated with 50ml pectin medium in a 250ml flask. Pure apple pectin (1.0%) was added to different flasks containing agar-free medium. The inoculated culture was placed in an orbital shaker at 160 rpm at 30°C for 5 days. Every day, remove 1ml of medium and check exo-PG activity.

[0037]exo-PG activity was measured by the dinitrosalicylic acid (DNS) method. An assay mix containing 0.5 ml of 0.1% polygalacturonic acid (w / v) and 0.1 ml of culture supernatant (crude enzyme) prepared in 50 mM sodium acetate buffer (pH 5) was incubated at 30 °C for 1...

Embodiment 2

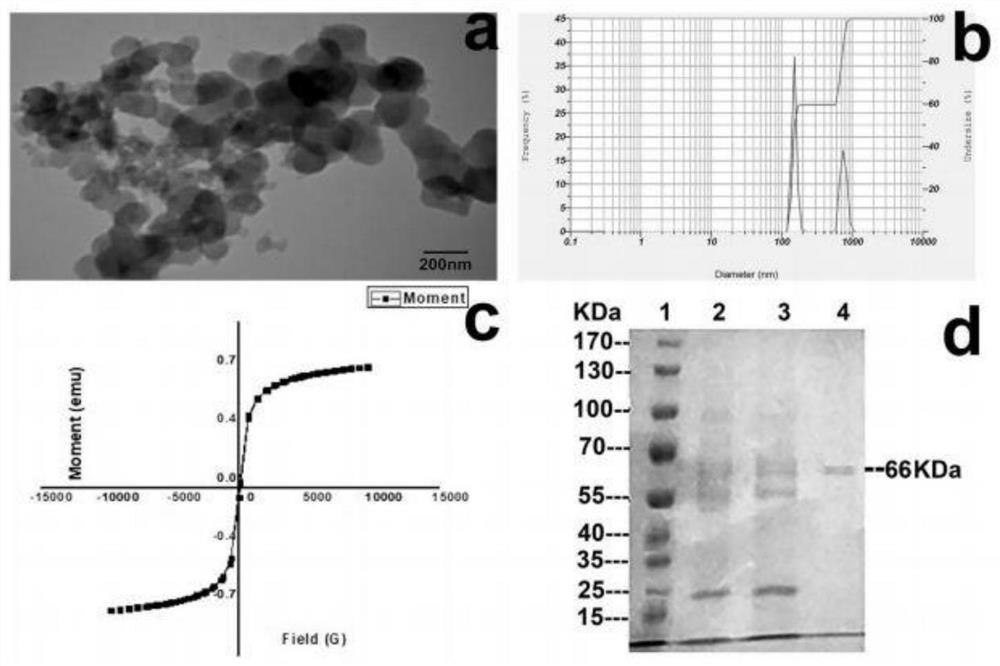

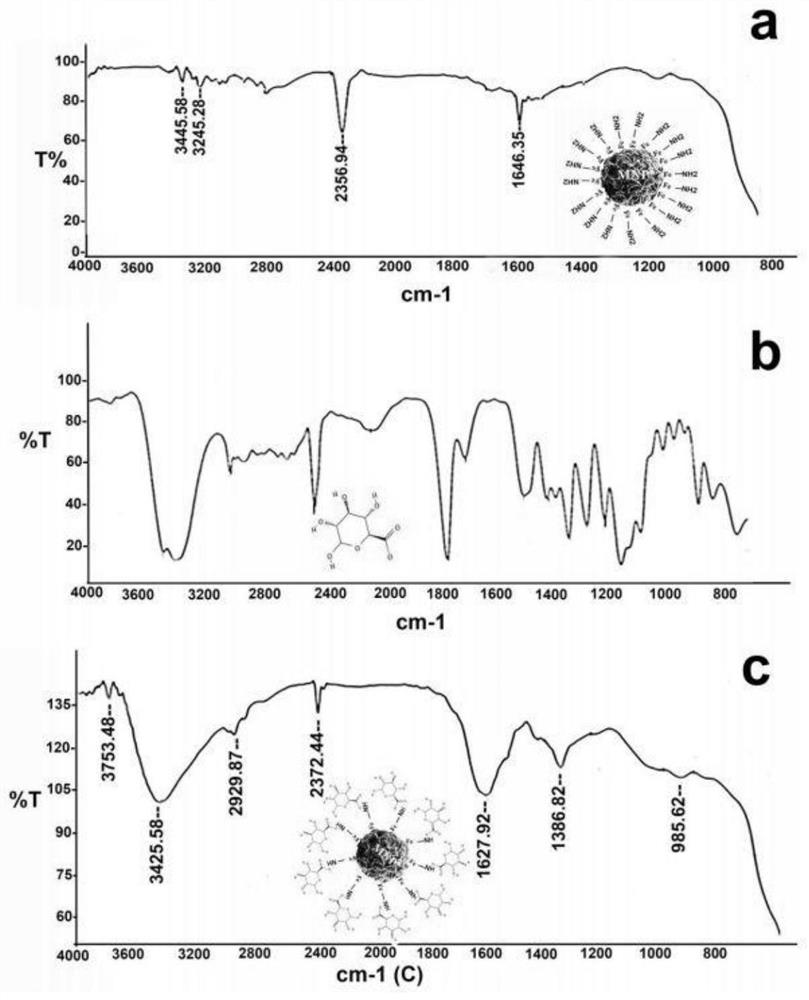

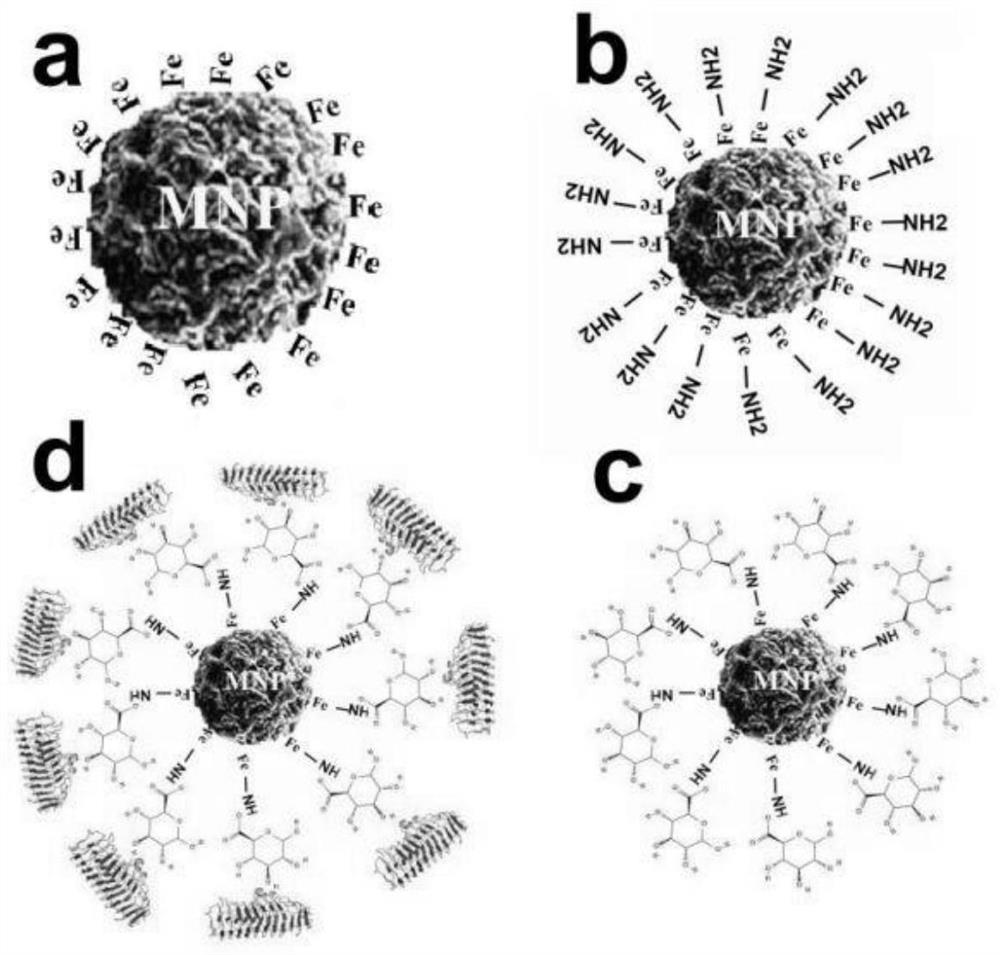

[0038] Example 2, the combination of magnetic nanoparticles (MNP) and galacturonic acid (Glt)

[0039] Suspend the magnetic nanoparticles (MNP) in double distilled water, and sonicate for 7-10 minutes, the particles that settle due to gravity are separated, and the remaining fine particles are suspended, and the particles are used to combine with galacturonic acid (0.4g), Dissolve in 120ml of distilled water and mix with 0.3g of MNP. The mixture was sonicated on ice for 4-5 min. Adjust with 1.M NaOH, pH 8, and incubate at 37°C for 15 minutes. 0.4 g of 1-ethyl-3-(3-dimethylaminopropyl)carbodiimide (EDAC) was added to the solution and adjusted with 1 M HCl, pH 6.4. The mixture was kept at 25°C for 6 hours with constant shaking. Finally 0.4 g of EDAC was added again and kept at 25°C for 20 hours with constant shaking. Bound nanoparticles were separated by applying an external magnetic field and washed five times with distilled water.

[0040] Before protein purification, mag...

Embodiment 3

[0045] Embodiment 3, the purification of exo-PG

[0046] The activity of exo-PG containing apple pectin (1%) was observed in glucose-free medium, which can be used for large-scale production of exo-PG. Inoculate 2ml of Aspergillus flavus dilution culture in about 250ml culture medium (10 10 / ml spores) and incubated in an orbital shaker at 30°C, 160rpm for 5 days. The medium was removed and filtered through sterile Whatman filter paper, and the clarified filtrate was used for purification of exo-PG.

[0047] exo-PG was purified directly from the culture filtrate. All purification steps were completed in an ice bath at 4 °C, about 1.0 g of Glt-MNP was mixed with 10 ml of culture filtrate, and incubated at 30 °C for 60 min with constant shaking. Glt-MNPs were removed from the solution by applying an external magnetic field and washed twice with PG buffer (10 mM Tris-Cl, pH 7.3). exo-PG bound to Glt-MNP was removed by mixing with 5 ml of elution buffer (0.3M NaCl in 10 mM Tri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com