A kind of carbon nanowire and its application in lithium battery

A carbon nanowire and carbon nanofiber technology, applied in the field of materials, can solve the problems of immature carbon nanowire preparation methods, unpopular carbon nanowires, etc., and achieve the effects of good electrochemical performance, simple and easy method, and easy adsorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

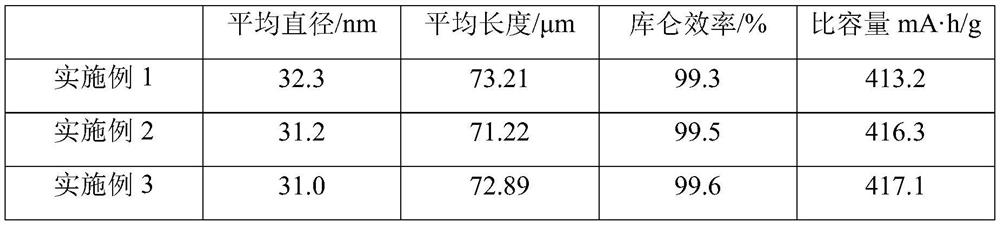

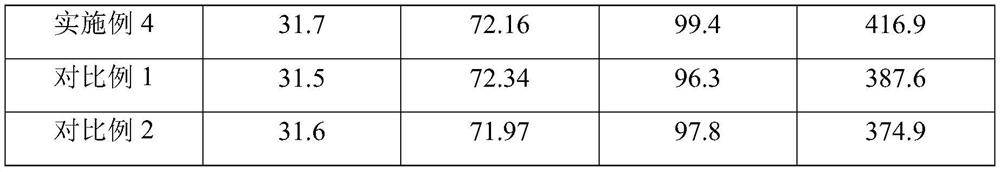

Examples

Embodiment 1

[0023] A carbon nanowire and its application in lithium batteries, comprising the following steps:

[0024] (1) Take 10 g of polyacrylonitrile, add it to 60 mL of N,N-dimethylformamide solvent, and stir at constant temperature for 12 hours to obtain a solution;

[0025] (2) Electrospinning was carried out under the conditions of spinning voltage 18kV, receiving distance 9cm, needle diameter 0.8mm, and advancing speed 0.50mL / h to obtain fibers;

[0026] (3) be placed in drying oven;

[0027] (4) Put it into a tube furnace after drying, heat up to 700°C under the protection of nitrogen at 5°C / min for carbonization, and obtain carbon fibers after natural cooling;

[0028] (5) Pulverize with a pulverizer to obtain carbon nanofibers;

[0029] (6) Lay the carbon nanofiber on the ground electrode in the low-temperature plasma treatment device and treat it for 10 minutes, wherein, the power supply frequency is 10kHz, the working voltage is 20kV, and the discharge power is 70W;

[0...

Embodiment 2

[0033] A carbon nanowire and its application in lithium batteries, comprising the following steps:

[0034] (1) Take 10 g of polyacrylonitrile, add it to 65 mL of N,N-dimethylformamide solvent, and stir at constant temperature for 12 hours to obtain a solution;

[0035] (2) Electrospinning was carried out under the conditions of spinning voltage 19kV, receiving distance 10cm, needle diameter 0.8mm, and advancing speed 0.50mL / h to obtain fibers;

[0036] (3) be placed in drying oven;

[0037] (4) Put it into a tube furnace after drying, heat up to 730°C under the protection of nitrogen at 5°C / min for carbonization, and obtain carbon fibers after natural cooling;

[0038] (5) Pulverize with a pulverizer to obtain carbon nanofibers;

[0039] (6) Lay the carbon nanofiber on the ground electrode in the low-temperature plasma treatment device and treat it for 12 minutes, wherein, the power frequency is 12kHz, the working voltage is 20kV, and the discharge power is 75W;

[0040] (...

Embodiment 3

[0043] A carbon nanowire and its application in lithium batteries, comprising the following steps:

[0044] (1) Take 10 g of polyacrylonitrile, add it to 70 mL of N,N-dimethylformamide solvent, and stir at constant temperature for 12 hours to obtain a solution;

[0045] (2) Electrospinning was carried out under the conditions of spinning voltage 20kV, receiving distance 10cm, needle diameter 0.8mm, and advancing speed 0.50mL / h to obtain fibers;

[0046] (3) be placed in drying oven;

[0047] (4) Put it into a tube furnace after drying, heat up to 700-800°C under the protection of nitrogen at 5°C / min for carbonization, and obtain carbon fibers after natural cooling;

[0048] (5) Pulverize with a pulverizer to obtain carbon nanofibers;

[0049] (6) Lay the carbon nanofiber on the ground electrode in the low-temperature plasma treatment device and treat it for 13 minutes, wherein, the power supply frequency is 13kHz, the working voltage is 20kV, and the discharge power is 75W; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com