Combined circulating spraying quick-freezing refrigeration house system and implementation method thereof

A circulating spray and combined technology, applied in cooling fluid circulation devices, refrigerators, coolers, etc., can solve the problems of unfavorable environmental protection and economic operation of cold storage, increase the operating cost of cold storage, increase dry consumption of stored food, etc., to achieve safety The effect of strong performance and stability, improving quality and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] The present invention will be further elaborated below through specific embodiments in conjunction with the accompanying drawings.

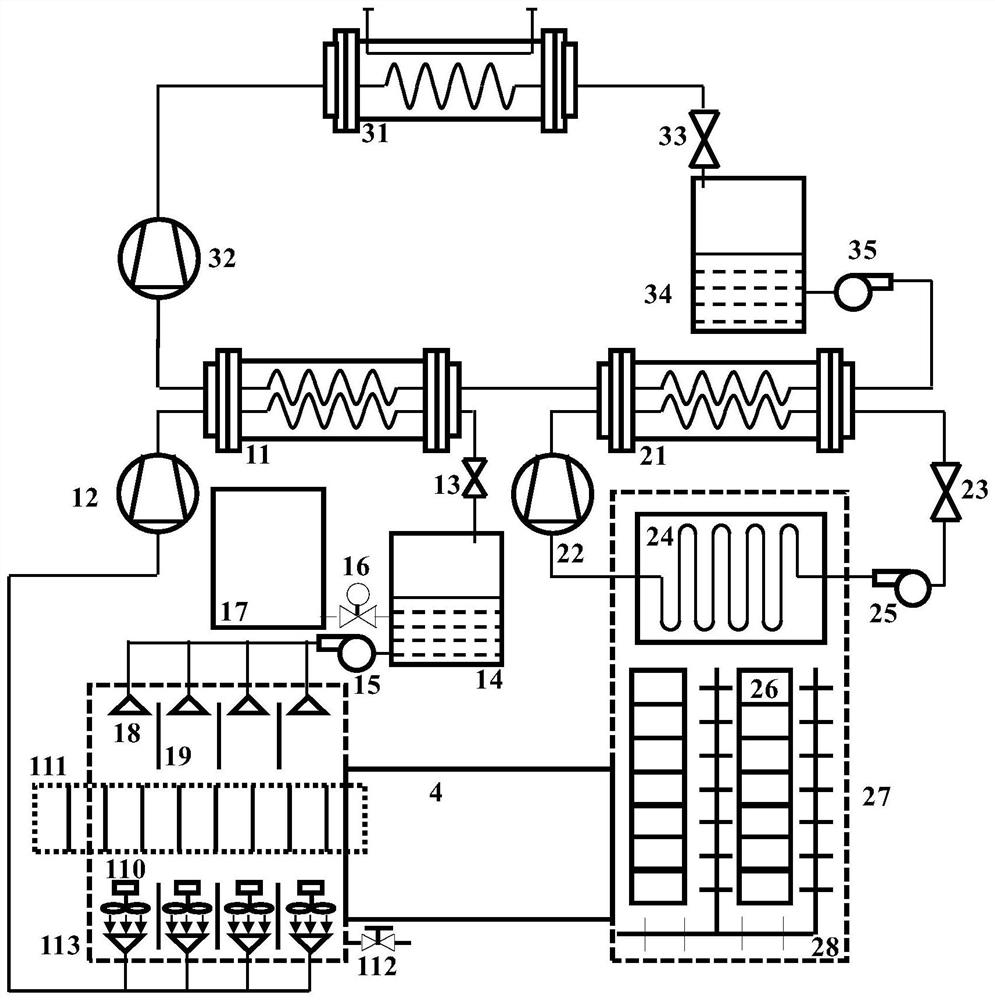

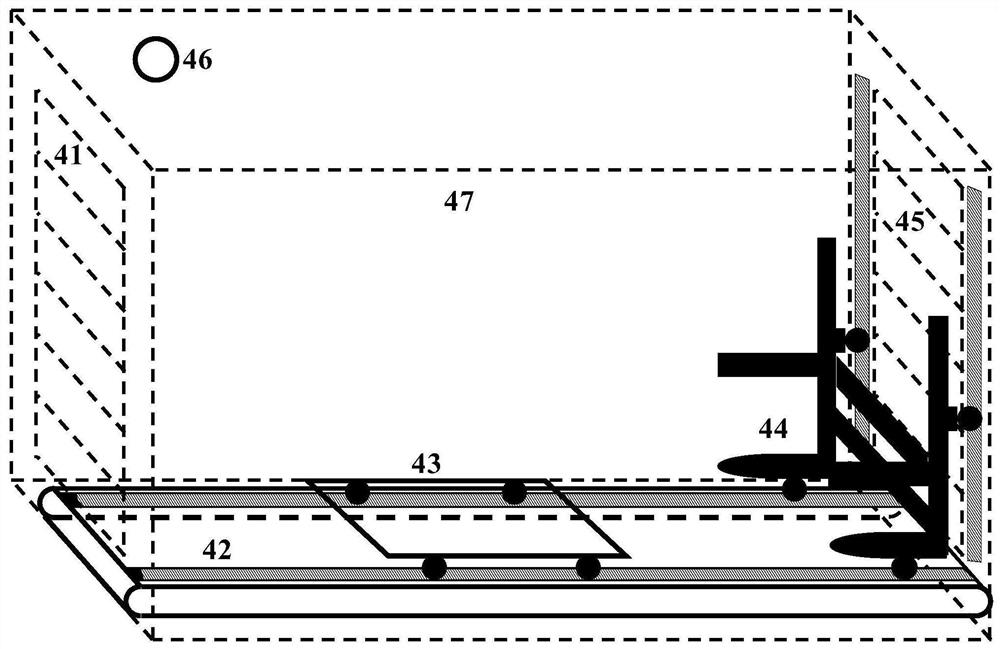

[0066] Such as figure 1 As shown, the combined circulating spray quick-freezing refrigerator system of this embodiment includes: circulating spray quick-freezing system, low-temperature storage system, high-temperature side refrigeration cycle system and intelligent sorting system;

[0067] The circulating spray quick-freezing system includes a spray liquid replenishment tank 17, a spray liquid reservoir 14, a first infusion pump 15, an electronic expansion valve 16, a single-fluid nozzle 18, a freezing chamber 113, a conveyor belt 111, a pressure regulating valve 112, Exhaust gas recovery device 110, first compressor 12, first cascade heat exchanger low-temperature channel and first throttle valve 13; among them, a plurality of evenly distributed single-fluid nozzles 18, air-inducing baffles, conveyor belt 111 and exhaust The gas recover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com