A laser-textured bionic capacitive flexible pressure sensor and its preparation method

A pressure sensor and capacitive technology, applied in the field of laser textured bionic capacitive flexible pressure sensor and its preparation, can solve the problem that it is difficult to realize rapid design and modification of templates and quickly prepare micro-structure capacitive flexible pressure sensors, and templates are difficult to compound a variety of Biomimetic structure, limited improvement of bionic structure performance, etc., to achieve the effect of easy batch preparation, improved measurement linear range, and expanded measurement linear range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

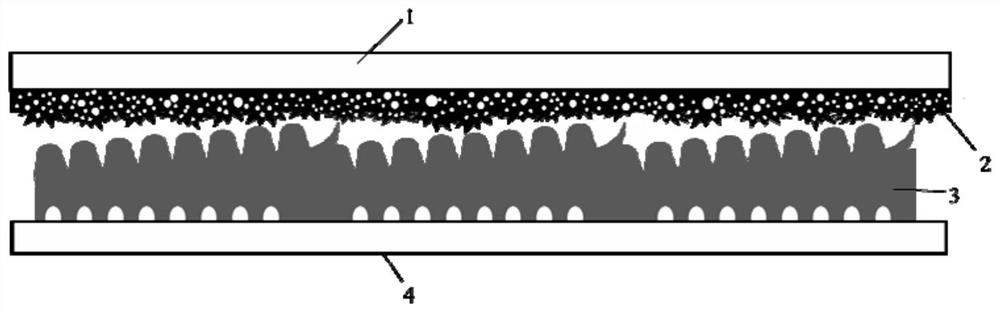

[0037] This embodiment provides a laser-textured bionic capacitive flexible pressure sensor, including a plurality of bionic butterfly scale laminated structures and bionic moth-eye structures, such as figure 1 As shown, in the schematic diagram of the laser texture bionic capacitive flexible pressure sensor, 1 is the upper electrode flexible substrate (1), 2 is the upper electrode conductive layer (2), 3 is the flexible dielectric layer (3), and 4 is the lower electrode A thin film (4), the upper electrode conductive layer (2) is a spongy porous structure conductive material, and the A side of the flexible dielectric layer (3) is an integrated bionic butterfly scale stacked structure array and a bionic moth-eye structure array; the The surface B of the flexible dielectric layer (3) is a microporous structure array.

Embodiment 2

[0039] This embodiment provides a preparation method of the laser-textured bionic capacitive flexible pressure sensor described in Embodiment 1, comprising the following steps:

[0040] (1) Pretreatment: select polydimethylsiloxane (PDMS) as the template material, prepare PDMS solution: mix the main agent and curing agent in a beaker according to the weight ratio of 10:1, stir with a glass rod for 15 minutes, put Vacuum in a vacuum box for 15 minutes to remove air bubbles for later use;

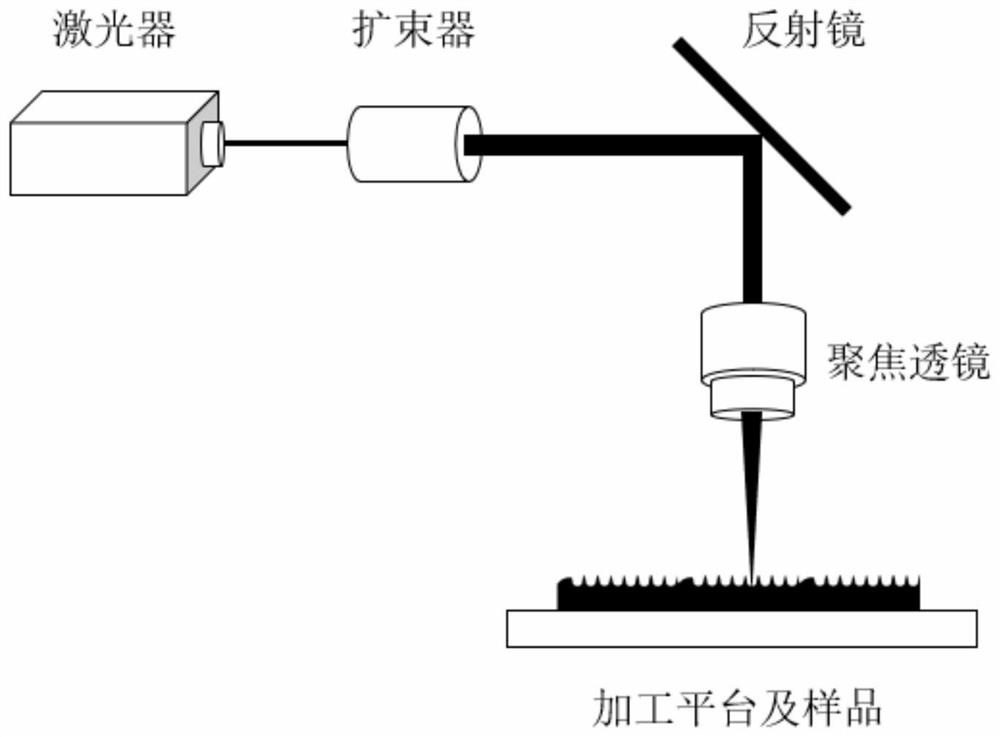

[0041] (2) Preparation of a flexible dielectric layer (3): Take an appropriate amount of PDMS mixed solution and spin-coat it on a smooth petri dish, and form a smooth film after curing. Using CO 2 The laser textured the surface of the smooth film to integrate the bionic butterfly scale structure and the bionic moth-eye structure template. The processing process is as follows: figure 2As shown, the three-dimensional schematic diagram of the integrated bionic butterfly scale structure and b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com