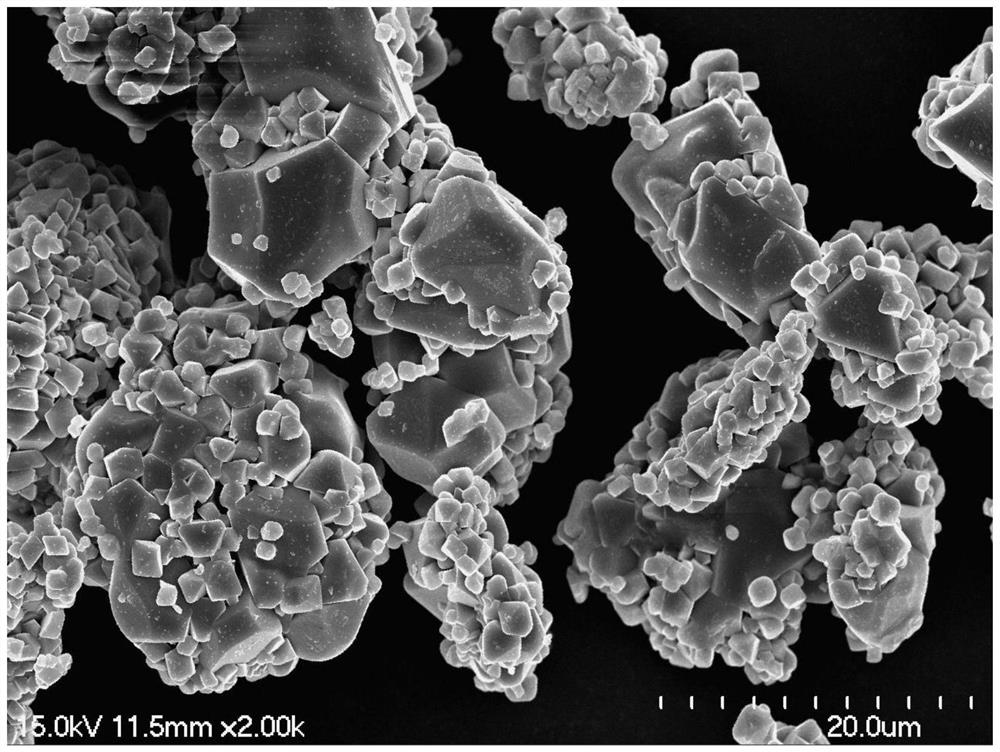

Preparation method of lithium manganate with low specific surface area and large particle size

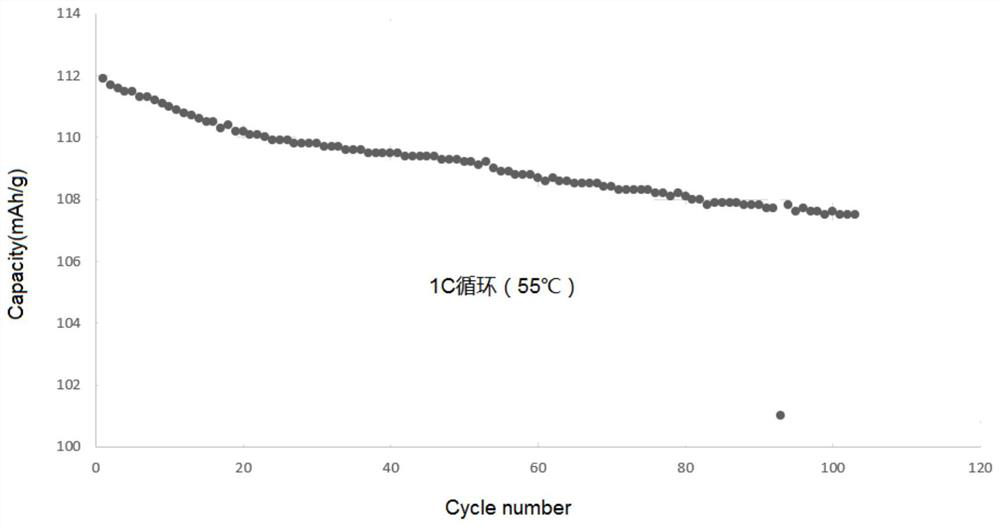

A technology of lithium manganate with low specific surface, large grain and diameter, applied in chemical instruments and methods, manganate/permanganate, manganese compounds, etc., can solve the problems of unsatisfactory cycle performance of lithium manganate and improve the cycle performance, low specific surface area, the effect of reducing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

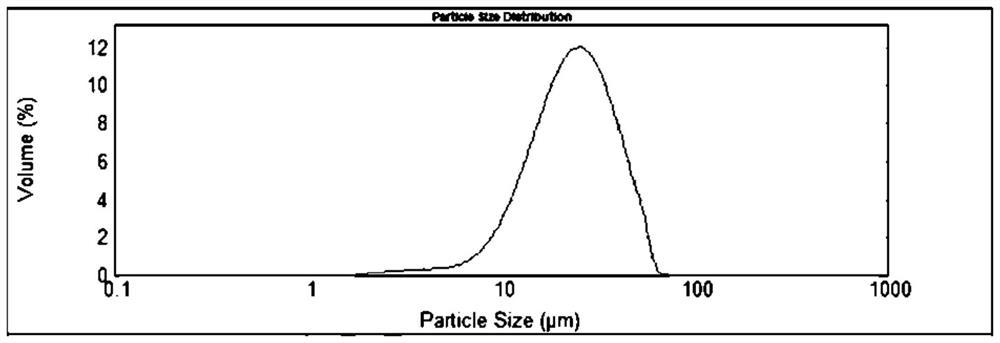

[0027] A kind of synthesis of lithium manganate Li1.12Mn1.88Al0.12O4 with low specific surface and large particle size is prepared according to the following steps:

[0028] Weigh battery-grade lithium carbonate and nano-alumina in a certain chemical ratio (this chemical ratio is a known ratio, which is omitted here), using deionized water as a grinding aid, zirconia balls as a ball milling medium, and a ball-to-material ratio of 8: 1. The solid content is 70%, and the horizontal ball mill is used for high-speed ball milling for 10 hours to obtain a uniform mixture with a particle size D50 of about 600nm. According to the metering ratio of 1.12:1.88, lithium hydroxide and manganese nitrate were respectively weighed and dissolved in ethanol solvent, and then the pH was adjusted with ammonia water to make it into a sol to obtain lithium manganate sol. Add 25% lithium manganate sol and manganese dioxide with a D50 of 18 μm to the aforementioned homogeneous mixture, turn on the ho...

Embodiment 2

[0031] A kind of synthesis of lithium manganate Li1.16Mn1.94Co0.03Y0.03O4 with low specific surface and large particle size is prepared according to the following steps:

[0032] Weigh battery-grade lithium carbonate, nano-scale cobaltous oxide, and nano-scale yttrium oxide in a certain chemical ratio (this chemical ratio is a known ratio, which is omitted here), using ethanol as a grinding aid, zirconia as a ball milling medium, and the ball material The ratio is 5:1, the solid content is 55%, and the horizontal ball mill is used for high-speed ball milling for 8 hours to obtain a uniform mixture with a particle size D50 of about 900nm. According to the metering ratio of 1.16:1.94, lithium hydroxide and manganese nitrate were respectively weighed and dissolved in ethanol solvent, and then the pH was adjusted with ammonia water to make it into a sol to obtain lithium manganate sol. Add 35% lithium manganate sol and trimanganese tetraoxide with a D50 of 10 μm to the aforementio...

Embodiment 3

[0034] A kind of synthesis of lithium manganate Li1.08Mn1.95Mg0.04Nb0.01O4 with low specific surface and large particle size is prepared according to the following steps:

[0035] Weigh battery-grade lithium carbonate, micron magnesium hydroxide, and micron niobium hydroxide in a certain chemical ratio (this chemical ratio is a known ratio, which is omitted here), use deionization as a grinding aid, and zirconia as a ball milling medium. The material ratio is 10:1, the solid content is 70%, and the horizontal ball mill is used for high-speed ball milling to obtain a uniform mixture with a particle size D50 of about 3 μm. According to the metering ratio of 1.08:1.96, lithium hydroxide and manganese nitrate were respectively weighed and dissolved in ethanol solvent, and then the pH was adjusted with ammonia water to make it into a sol to obtain lithium manganate sol. Add 10% lithium manganate sol and manganese dioxide with a D50 of 15 μm to the aforementioned homogeneous mixture...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Specific surface | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com