CNF-stabilized styrene-acrylic emulsion as well as preparation method and application thereof

A styrene-acrylic emulsion, stable technology, applied in the direction of adding enhancer, no pigment coating, coating, etc., can solve the problems of coating defects, coating adhesion, adverse effects of weather resistance, etc., to achieve short production cycle, improve Substrate strength and barrier properties, the effect of good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

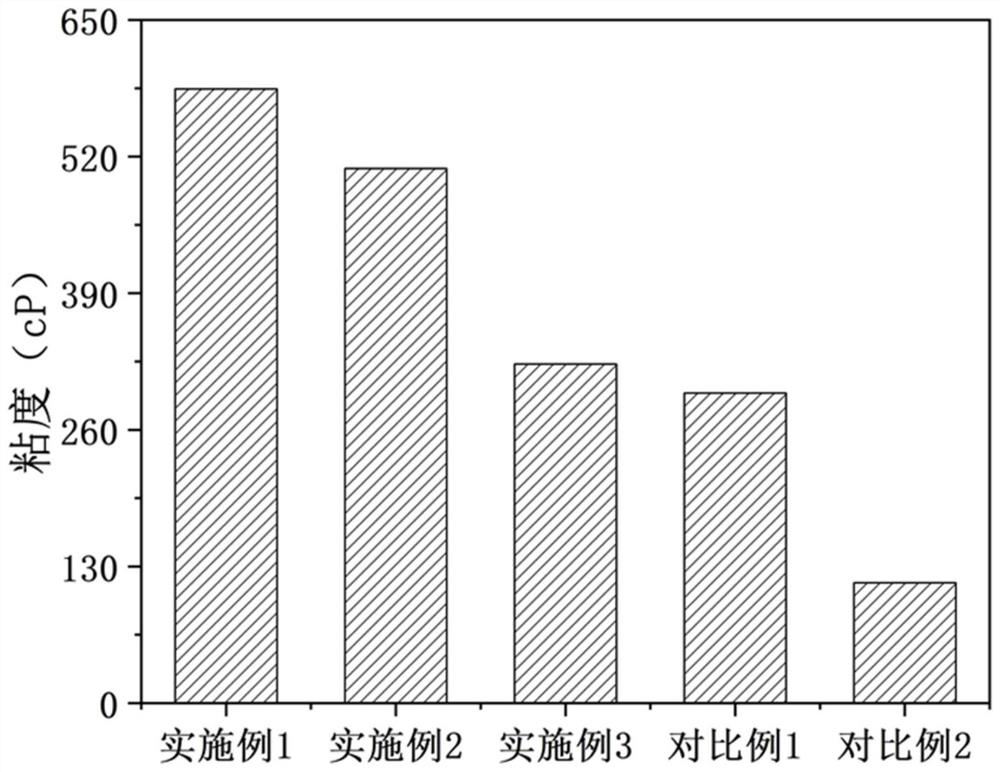

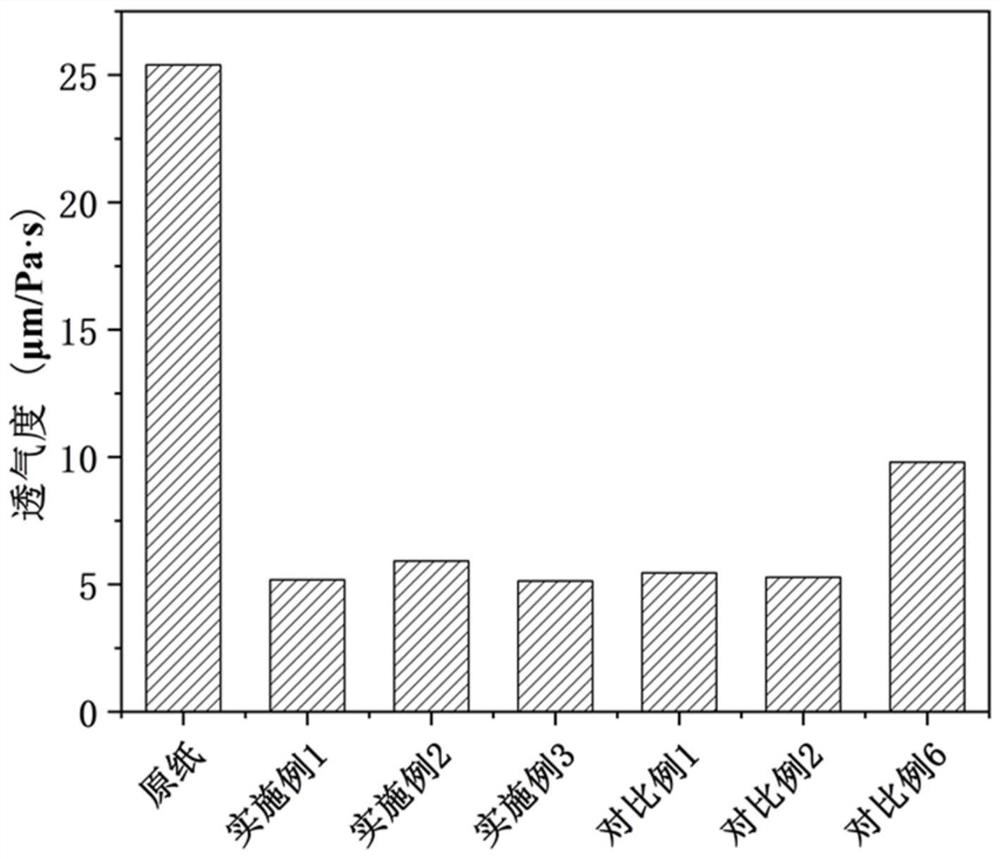

[0050] (1) Methyl methacrylate (MMA), butyl acrylate (BA) and styrene (St) were prepared into a monomer mixture in a ratio of 4:5:1 (mass ratio), and the concentration was 1 wt%. cellulose nanofibrils (CNF) suspension to obtain a CNF-monomer mixture; wherein the amount of the CNF suspension is 90% of the total mass of the CNF-monomer mixture; use a high-speed stirrer to mechanically disperse at a speed of 650rpm for 10min , and the CNF-monomer emulsion was obtained after ultrasonic emulsification for 30 min, wherein the ultrasonic power was 1200W.

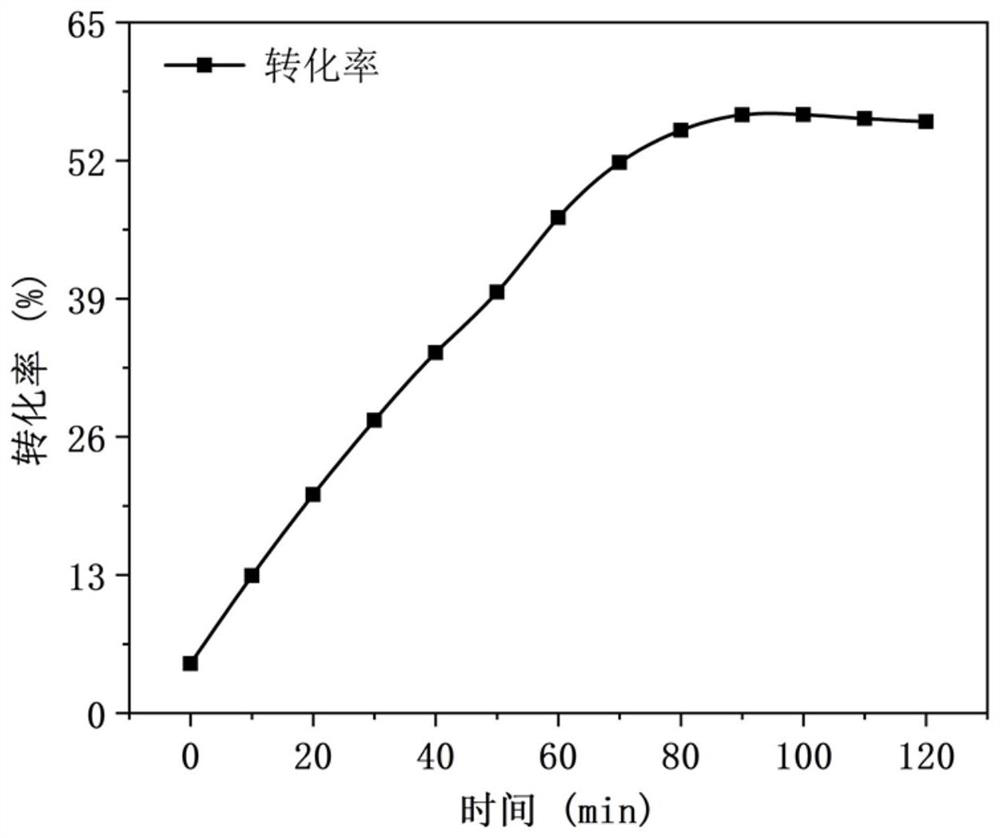

[0051] (2) In the CNF-monomer emulsion, add initiator ammonium persulfate, the addition is 0.6% of the monomer mixed liquid quality in the step (1), mix well; then take out 25wt% CNF-monomer emulsion containing initiator Join in the reactor as seed emulsion, and add sodium bicarbonate, the addition amount of sodium bicarbonate is 0.2% of the monomer mixture liquid quality in the step (1); Under the stirring speed of 100rpm, be warm...

Embodiment 2

[0053] (1) Methyl methacrylate (MMA), butyl acrylate (BA) and styrene (St) were prepared into a monomer mixture in a ratio of 4:5:1 (mass ratio), and the concentration was added at 0.8wt % CNF suspension to obtain a CNF-monomer mixture; wherein the amount of CNF suspension is 90% of the total mass of the CNF-monomer mixture; use a high-speed mixer to mechanically disperse at a speed of 650rpm for 10 minutes, and then undergo ultrasonic emulsification for 30 minutes Finally, a CNF-monomer emulsion was obtained, wherein the ultrasonic power was 1200W.

[0054] (2) In the CNF-monomer emulsion, add initiator ammonium persulfate, the addition is 0.6% of the monomer mixed liquid quality in the step (1), mix well; then take out 25wt% CNF-monomer emulsion containing initiator Join in the reactor as seed emulsion, and add sodium bicarbonate, the addition amount of sodium bicarbonate is 0.2% of the monomer mixture liquid quality in the step (1); Under the stirring speed of 100rpm, be wa...

Embodiment 3

[0056] (1) Methyl methacrylate (MMA), butyl acrylate (BA) and styrene (St) were prepared into a monomer mixture in a ratio of 4:5:1 (mass ratio), and the concentration of 0.6wt % CNF suspension to obtain a CNF-monomer mixture; wherein the amount of CNF suspension is 90% of the total mass of the CNF-monomer mixture; use a high-speed mixer to mechanically disperse at a speed of 650rpm for 10 minutes, and then undergo ultrasonic emulsification for 30 minutes Finally, a CNF-monomer emulsion was obtained, wherein the ultrasonic power was 1200W.

[0057] (2) In the CNF-monomer emulsion, add initiator ammonium persulfate, the addition is 0.6% of the monomer mixed liquid quality in the step (1), mix well; then take out 25wt% CNF-monomer emulsion containing initiator Join in the reactor as seed emulsion, and add sodium bicarbonate, the addition amount of sodium bicarbonate is 0.2% of the monomer mixture liquid quality in the step (1); Under the stirring speed of 100rpm, be warming up t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com