A kind of petroleum asphalt/ferric oxide composite wave absorbing agent and its preparation method, wave absorbing material

A technology of ferric tetroxide and petroleum asphalt, which is used in building thermal insulation materials, magnetic field/electric field shielding, building components, etc. Conductivity, enhanced magnetic loss performance, stable modification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

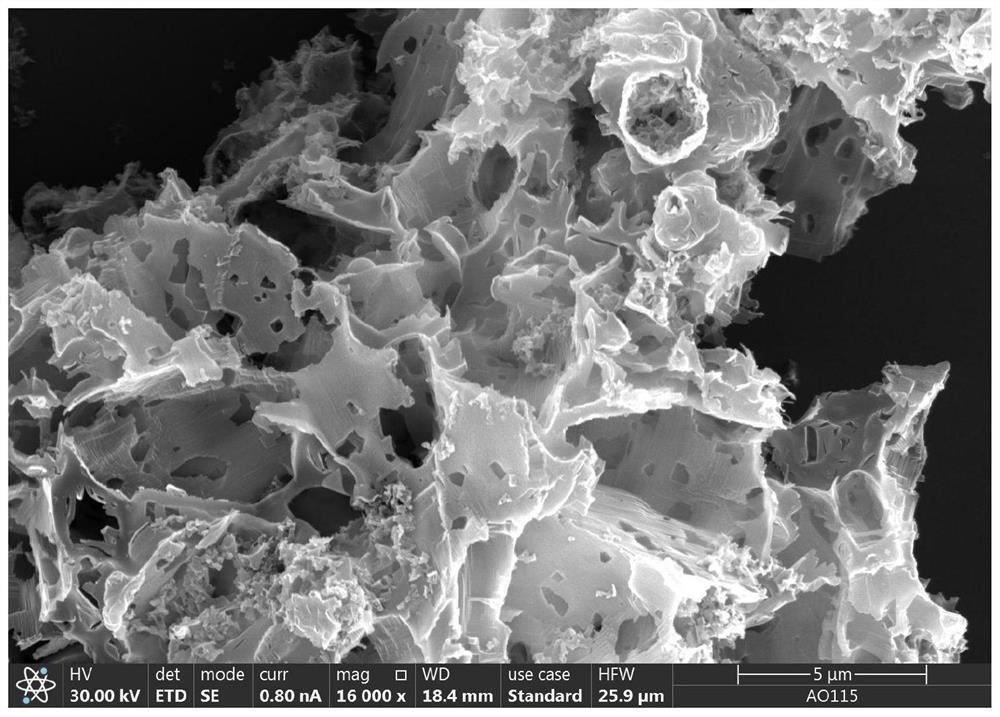

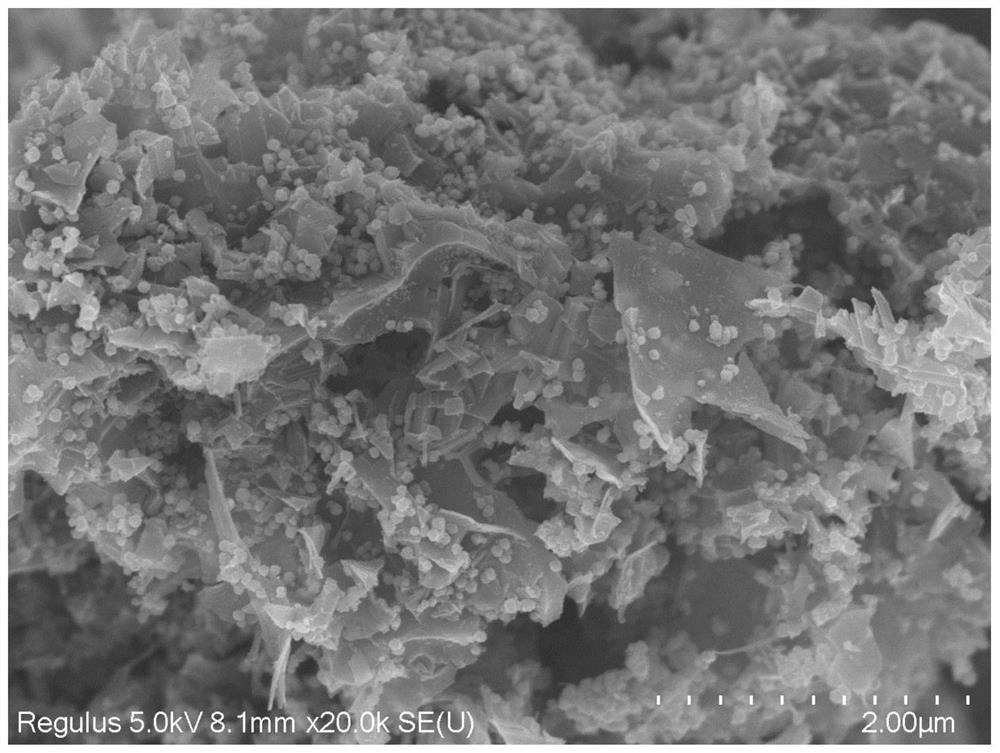

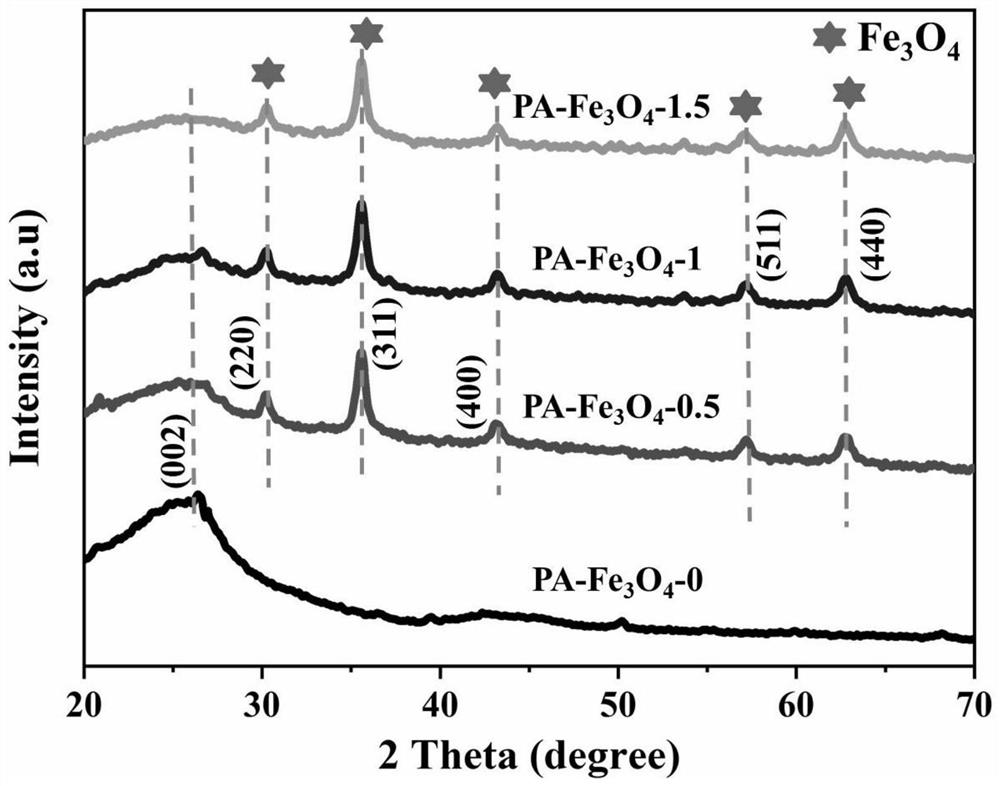

[0024] The invention provides a preparation method of a petroleum asphalt / ferric oxide composite wave absorbing agent, comprising the following steps: pyrolyzing a mixture of petroleum asphalt and sodium chloride to obtain pyrolyzed asphalt;

[0025] Ferric chloride hexahydrate, anhydrous acetate, polyethylene glycol, ethylene glycol and pyrolysis asphalt are mixed, and the obtained mixed solution is subjected to solvothermal reaction to obtain a petroleum asphalt / ferric oxide composite wave absorbing agent.

[0026] In the present invention, unless otherwise specified, the raw materials used are commercially available products well known in the art.

[0027] The invention pyrolyzes the mixture of petroleum asphalt and sodium chloride to obtain pyrolysis asphalt.

[0028] In the present invention, the mass ratio of the petroleum pitch to sodium chloride is preferably 1:4. Prior to pyrolysis, the present invention preferably ball mills the mixture of petroleum pitch and sodium...

Embodiment 1

[0049] After weighing 0.5g of powdered petroleum pitch and 2g of sodium chloride, pour the two powders into a ball mill tank, and ball mill for 9 hours under dry milling conditions. After the ball milling, take out the powder and transfer it to a tube furnace for pyrolysis , the temperature is 900°C, and Ar gas is used throughout the experiment. After the experiment is over, the instrument is turned off to allow the entire device to cool down to room temperature naturally, and the powder is taken out;

[0050] The obtained powder was repeatedly rinsed with deionized water, and then placed in a drying oven for drying treatment. The temperature was set at 80°C, and the drying time was 18 hours. After drying, pyrolysis pitch was obtained;

[0051] Weigh 3.2g of anhydrous sodium acetate, 1g of polyethylene glycol-2000, 0.26g of ferric chloride hexahydrate and 300mg of pyrolyzed asphalt and disperse them into a beaker containing 40mL of ethylene glycol, and stir thoroughly at a temp...

Embodiment 2

[0053] After weighing 0.5g of powdered petroleum pitch and 2g of sodium chloride, pour the two powders into a ball mill tank, and ball mill for 9 hours under dry milling conditions. After the ball milling, take out the powder and transfer it to a tube furnace for pyrolysis , the temperature is 900°C, and Ar gas is used throughout the experiment. After the experiment is over, the instrument is turned off to allow the entire device to cool down to room temperature naturally, and the powder is taken out;

[0054] The obtained powder was repeatedly rinsed with deionized water, and then placed in a drying oven for drying treatment. The temperature was set at 80°C, and the drying time was 18 hours. After drying, pyrolysis pitch was obtained;

[0055] Weigh 3.2g of anhydrous sodium acetate, 1g of polyethylene glycol-2000, 0.52g of ferric chloride hexahydrate and 300mg of pyrolytic pitch and disperse them into a beaker filled with 40mL of ethylene glycol, and stir thoroughly at a tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| absorption bandwidth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com