Element-doped transition metal sulfide ultrathin sheet and preparation and application thereof

A transition metal and element doping technology, applied in the direction of hydrocarbon production from carbon oxides, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The invention discloses a method for preparing an element-doped transition metal sulfide ultrathin sheet, which comprises the following steps:

[0041]S1. Disperse the salt, doping element and transition metal source in water or solvent for heating reaction, and obtain the precursor after drying;

[0042] S2. Using sulfur powder as a sulfur source, calcining the precursor in an inert atmosphere at 150-400° C. to obtain element-doped transition metal sulfide ultrathin flakes.

[0043] In the present invention, the mass ratio of the salt, doping element and transition metal source is 100-1000:1-500:100-1000; in some specific embodiments, the salt, doping element and transition metal The mass ratio of the source is 200-500:3-100:200-500; the mass ratio of the salt, doping element and transition metal source is preferably 100:200:400.

[0044] The above reaction is carried out in a solvent, which is well known to those skilled in the art, and the present invention is not p...

Embodiment 1

[0078] Add 100 parts of sodium sulfate, 1 part of nickel acetate tetrahydrate and 100 parts of cobalt acetate tetrahydrate to 20 parts of water, stir vigorously at room temperature, pre-cool the resulting reaction solution, put it into a freeze dryer, and freeze-dry it for 24 hours to obtain a precursor Powder: Take the obtained precursor powder in a tube furnace, put 100 parts of sulfur powder at the front end of the tube furnace, calcinate at 180-300 degrees Celsius for 1 hour in a high-purity argon atmosphere, take out the powder product after natural cooling, wash and centrifuge The sample is obtained, and the powder obtained by drying the sample in a vacuum oven at 60°C for 10 h is nickel-doped cobalt disulfide ultrathin flakes.

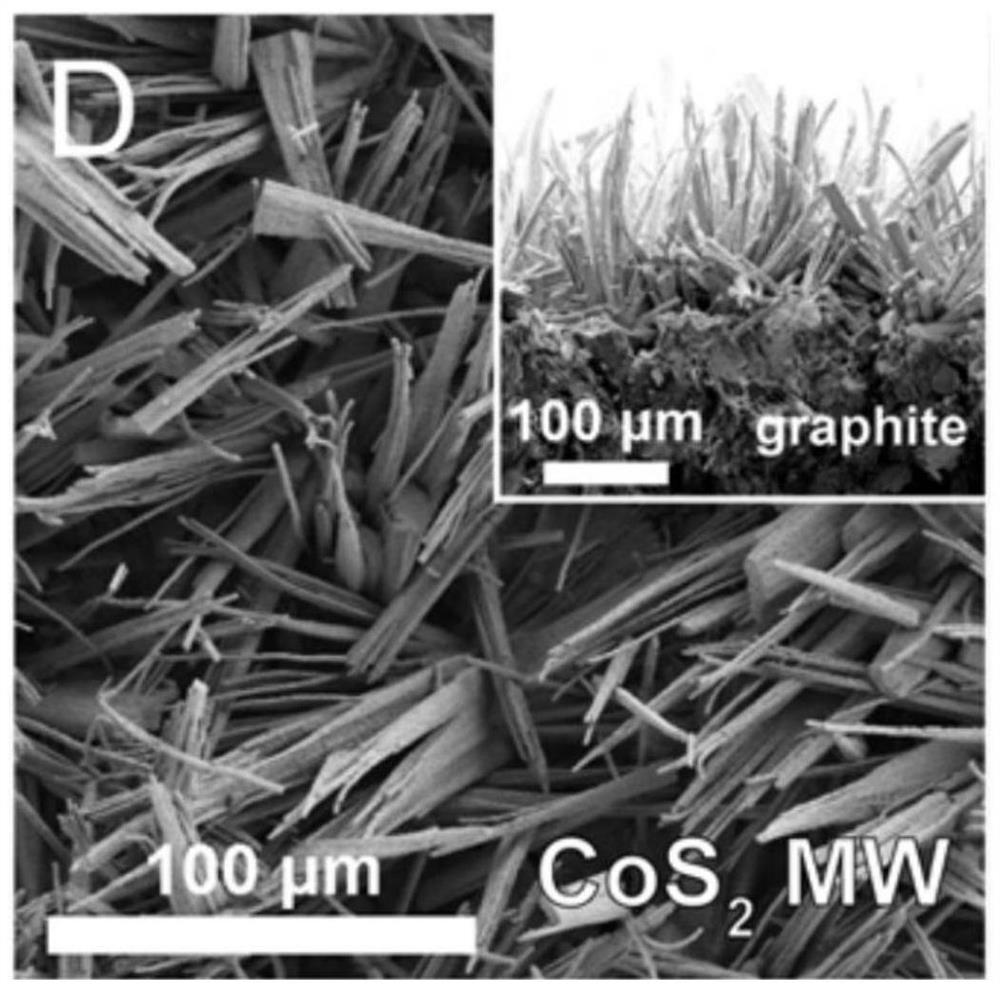

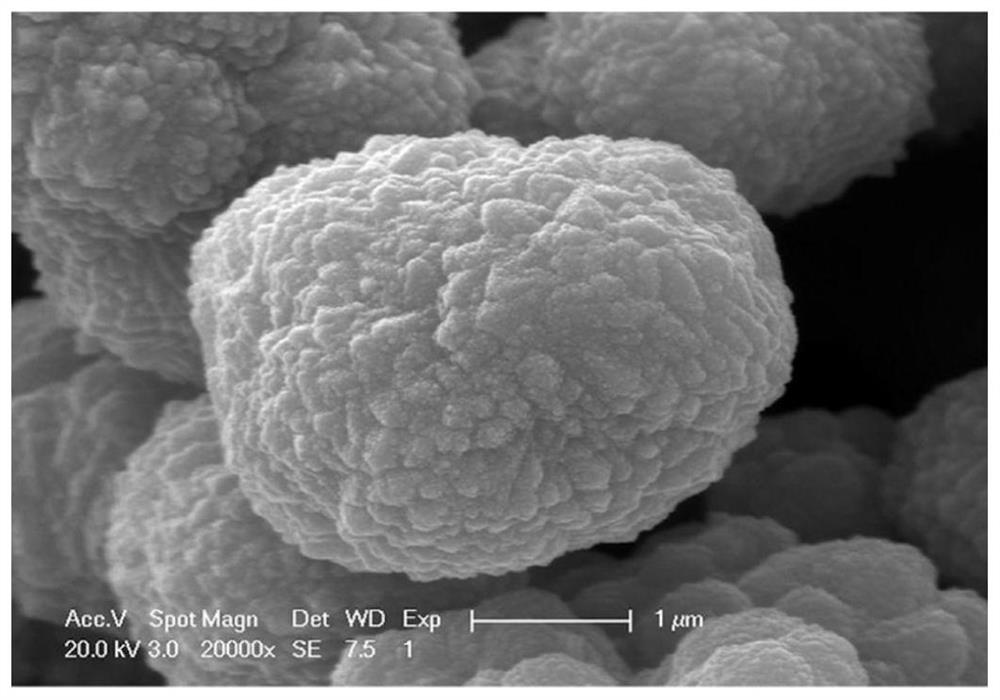

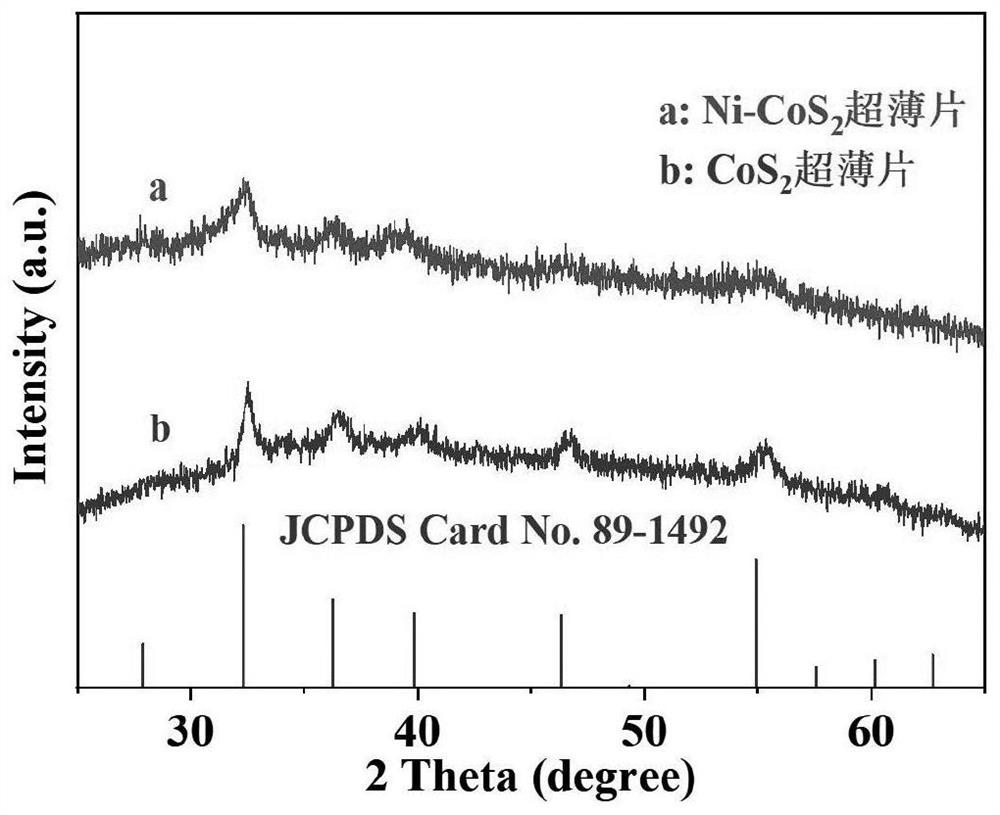

[0079] The compound prepared in Example 1 is carried out structural identification, the results are shown in Figure 3 ~ Figure 5 , image 3 The middle a curve is the X-ray diffraction (XRD diffraction) pattern of the nickel-doped cobalt disulf...

Embodiment 2

[0081] Add 1000 parts of sodium sulfate, 500 parts of nickel acetate tetrahydrate and 1000 parts of cobalt acetate tetrahydrate to 40 parts of water, stir vigorously at room temperature, pre-cool the resulting reaction solution, put it into a freeze dryer, and freeze-dry it for 24 hours to obtain a precursor Powder: Take the obtained precursor powder in a tube furnace, put 1000 parts of sulfur powder at the front end of the tube furnace, calcinate at 180-300 degrees Celsius for 1 hour in a high-purity argon atmosphere, take out the powder product after natural cooling, wash and centrifuge The sample is obtained, and the powder obtained by drying the sample in a vacuum oven at 60°C for 10 h is nickel-doped cobalt disulfide ultrathin flakes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com