Preparation method and application of purple phosphorus/graphene composite material

A composite material and graphene technology, applied in the field of gas sensors, can solve the problems of being unsuitable for on-site real-time detection, inconvenient to carry, and expensive, and achieve the effects of low cost, improved efficiency, and improved electrical conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] A kind of preparation method of purple phosphorus / graphene composite material of the present invention, comprises the following steps:

[0038] S1. Prepare graphene on the surface of copper foil by chemical vapor deposition. The number of layers of graphene is 2 to 20 layers. Put the copper foil sample loaded with graphene into the etching solution for 2 to 4 hours and wait for the sample to After the copper is completely etched, use filter paper to transfer the graphene to deionized water for 30-60 minutes for cleaning, then transfer to new deionized water for 30-60 minutes, and finally transfer the graphene to the substrate;

[0039] The corrosion solution is a mixed solution of ferric chloride and hydrochloric acid, wherein the ferric chloride solution and the hydrochloric acid solution are mixed at a volume ratio of 1:1, and the concentration is 0.1-1mol / L.

[0040] The substrate is Si / SiO 2 , glass or organic membrane.

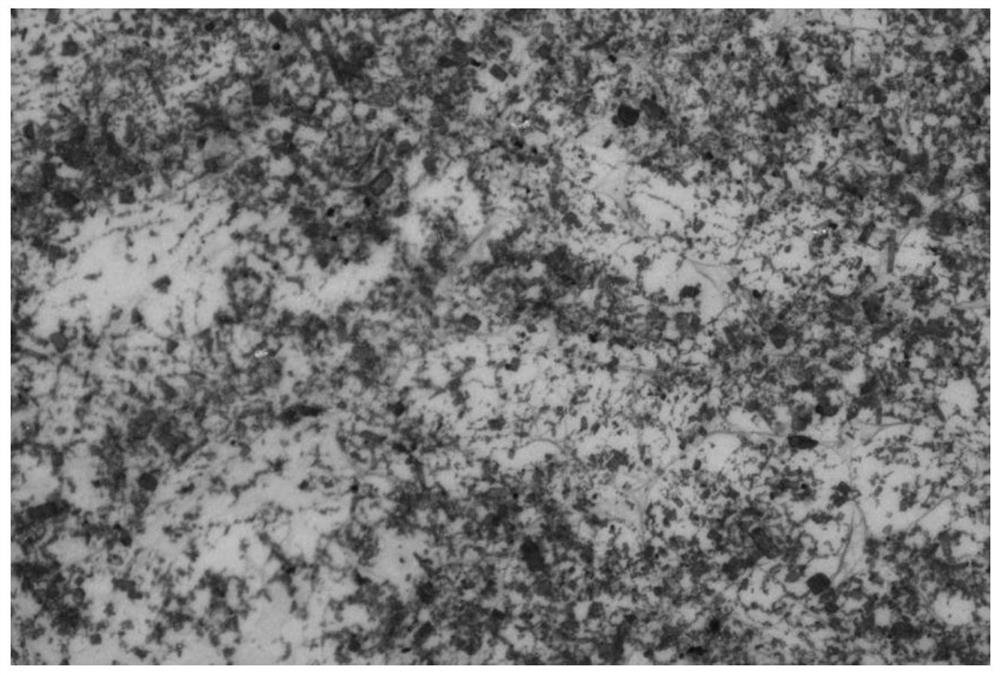

[0041] S2. Exfoliate the massive purple ph...

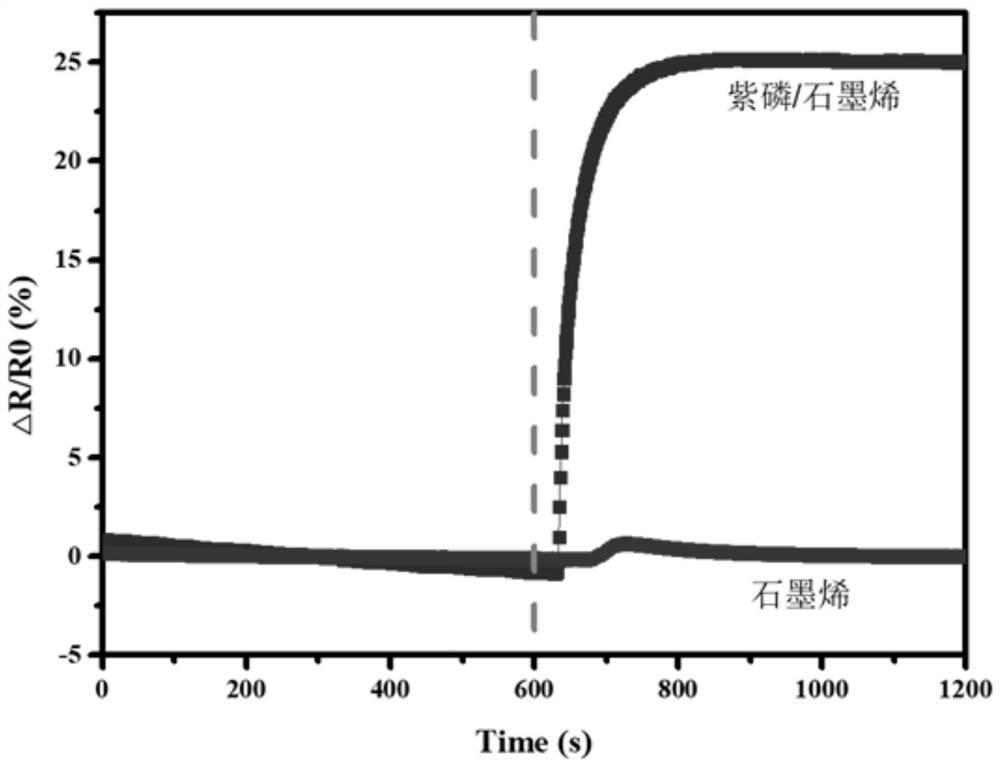

Embodiment 1

[0048]The purple phosphorus was peeled off by physical method and transferred to the surface of graphene to recombine with it, and the adsorption and desorption performance of the purple phosphorus / graphene composite material on carbon monoxide and nitrogen monoxide was detected. Concrete preparation steps are as follows:

[0049] (1) Graphene transfer

[0050] Prepare FeCl with a concentration of 1mol / l 3 / HCl solution is used to etch copper, and the graphene / copper foil with an area of 10mm*10mm is cut and placed on the surface of the etching solution. After etching for 2 hours, the graphene was transferred to deionized water with filter paper, soaked for 30 minutes, then transferred to new deionized water, soaked for 30 minutes, and transferred to an organic filter membrane.

[0051] (2) Purple phosphorus stripping

[0052] Put 10 mg of bulk purple phosphorus into a mortar, add a small amount of absolute ethanol and grind until the powder is matte without obvious parti...

Embodiment 2

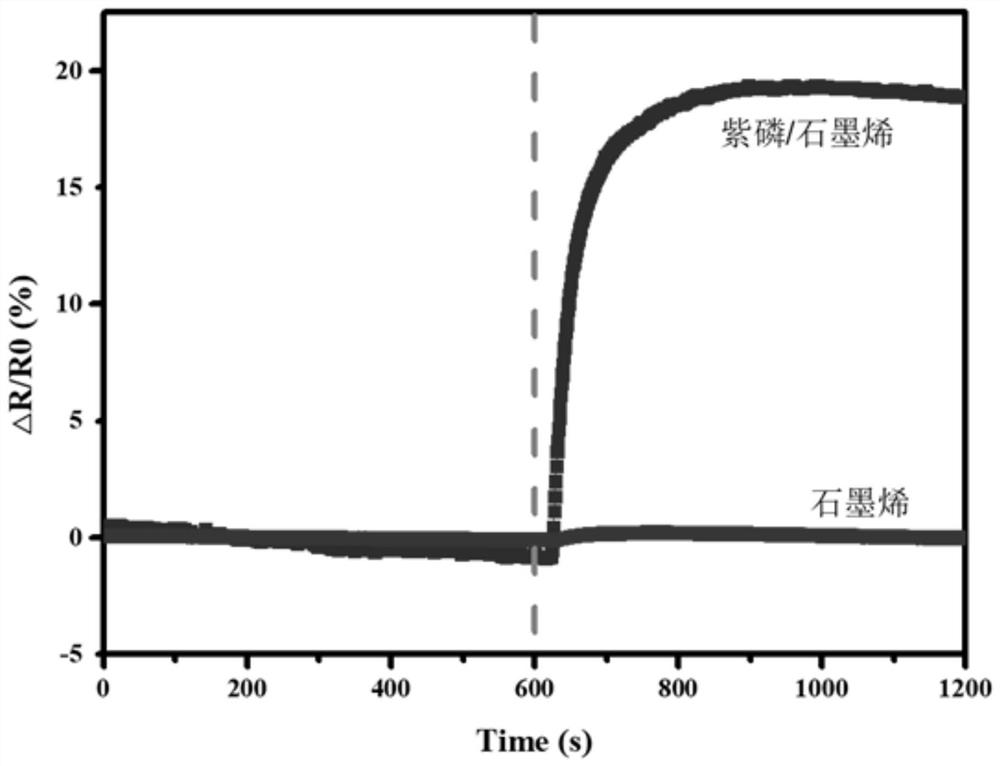

[0058] The purple phosphorus was peeled off by physical method and then transferred to the surface of graphene to recombine with it, and the adsorption and desorption performance of the purple phosphorus / graphene composite material on nitric oxide was detected. Concrete preparation steps are as follows:

[0059] (1) Graphene transfer

[0060] Prepare FeCl with a concentration of 0.1mol / l 3 / HCl solution is used to etch copper, and the graphene / copper foil with an area of 10mm*10mm is cut and placed on the surface of the etching solution. After etching for 3 hours, transfer the graphene to deionized water with filter paper, soak for 40 minutes, then transfer to new deionized water, soak for 40 minutes, and transfer to Si / SiO 2 , Glass substrate.

[0061] (2) Purple phosphorus stripping

[0062] Put 10 mg of bulk purple phosphorus into a mortar, add a small amount of absolute ethanol and grind until the powder is matte without obvious particles. After grinding, the powder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com