Preparation method of ammonium heptamolybdate

A technology of ammonium heptamolybdate and ammonium molybdate, applied in the field of ammonium heptamolybdate preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

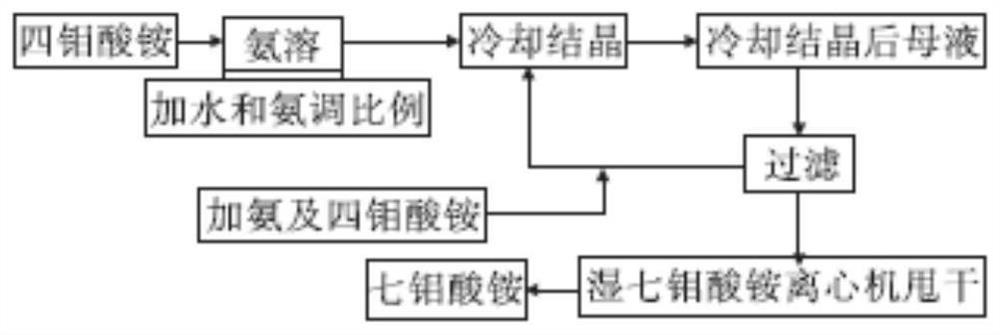

Image

Examples

Embodiment 1

[0049] The preparation method of ammonium heptamolybdate, comprises the following steps:

[0050] (1) Molybdenum calcine water elution of nitrate

[0051] The molybdenum calcine in this example was purchased from Jiangxi Copper Co., Ltd. Dexing Copper Mine, and the molybdenum calcine was acid-washed molybdenum calcine with nitric acid. Therefore, the acid-washed molybdenum calcine contained a certain amount of nitrate (~0.5%). If the acid-washed molybdenum calcine is directly subjected to alkaline oxygen pressure leaching, nitrate radicals will enter the leaching solution, and nitrate radicals will gradually reduce the organic phase extraction capacity of alkaline extraction. root. The slurry is mixed and washed in a steel stirring reaction kettle, and then multi-stage countercurrent washing is carried out by an automatic diaphragm box filter press until the nitrate content in the molybdenum calcine is less than 0.01%. The out-of-stock molybdenum calcine enters the alkaline ...

Embodiment 2

[0078] The preparation method of ammonium heptamolybdate, comprises the following steps:

[0079] (1) Molybdenum calcine water elution of nitrate

[0080] The molybdenum calcine in this example was purchased from Jiangxi Copper Co., Ltd. Dexing Copper Mine, and the molybdenum calcine was acid-washed molybdenum calcine with nitric acid. Therefore, the acid-washed molybdenum calcine contained a certain amount of nitrate (~0.5%). If the acid-washed molybdenum calcine is directly subjected to alkaline oxygen pressure leaching, nitrate radicals will enter the leaching solution, and nitrate radicals will gradually reduce the organic phase extraction capacity of alkaline extraction. root. The slurry is mixed and washed in a steel stirring reaction kettle, and then multi-stage countercurrent washing is carried out by an automatic diaphragm box filter press until the nitrate content in the molybdenum calcine is less than 0.01%. The out-of-stock molybdenum calcine enters the alkaline ...

Embodiment 3

[0093] The preparation method of ammonium heptamolybdate, comprises the following steps:

[0094] (1) Molybdenum calcine water elution of nitrate

[0095] The molybdenum calcine in this example was purchased from Jiangxi Copper Co., Ltd. Dexing Copper Mine, and the molybdenum calcine was acid-washed molybdenum calcine with nitric acid. Therefore, the acid-washed molybdenum calcine contained a certain amount of nitrate (~0.5%). If the acid-washed molybdenum calcine is directly subjected to alkaline oxygen pressure leaching, nitrate radicals will enter the leaching solution, and nitrate radicals will gradually reduce the organic phase extraction capacity of alkaline extraction. root. The slurry is mixed and washed in a steel stirring reaction kettle, and then multi-stage countercurrent washing is carried out by an automatic diaphragm box filter press until the nitrate content in the molybdenum calcine is less than 0.01%. The out-of-stock molybdenum calcine enters the alkaline ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com