Preparation method of polyether polyol for super-soft slow-rebound foam

A polyether polyol and slow rebound technology, which is applied in the field of preparation of polyether polyol for super soft and slow rebound foam, can solve the problems of inability to improve foam softness and low compression residue, and achieve low compression permanent deformation, The effect of fewer side reaction products and excellent physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

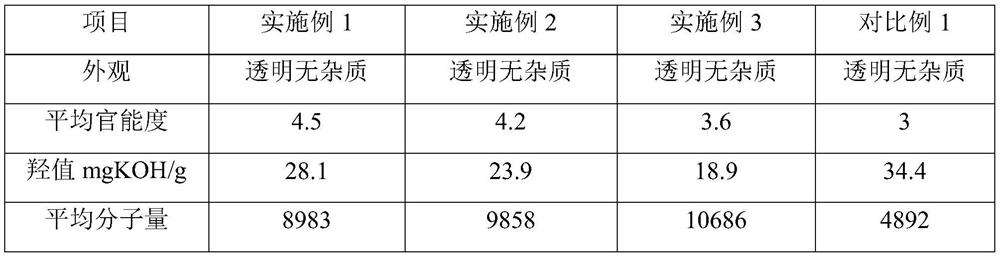

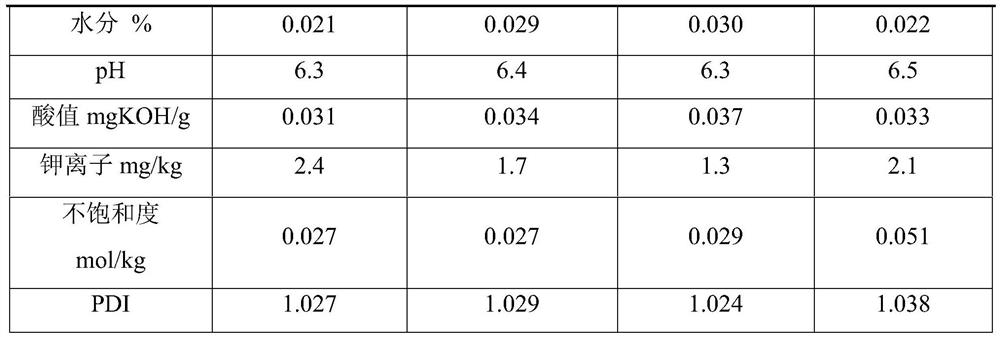

Examples

Embodiment 1

[0027] Add 92g of glycerin, 182g of sorbitol, and 40g of potassium hydroxide to the pressure-resistant reaction kettle, replace with nitrogen to make the oxygen content in the kettle less than 50ppm, and then add 431g of propylene oxide and 1295g of ethylene oxide at a temperature of 108-112°C Carry out a preliminary polymerization reaction, and after the reaction is completed, continue the internal pressure reaction for 3 hours to fully react the added propylene oxide and ethylene oxide, remove unreacted monomers, and obtain the intermediate polyether polyol.

[0028] Add 202g of intermediate polyether polyol and 2.0g of phosphazene catalyst into a pressure-resistant reaction kettle and mix them, replace with nitrogen to make the oxygen content in the kettle less than 50ppm, and blow with nitrogen at a temperature of 93-95°C and a vacuum of less than -0.09MPa Bubble timer 2h. Feed 434g of propylene oxide and 1303g of ethylene oxide in proportion at a temperature of 113-117°C ...

Embodiment 2

[0031] Add 110g of glycerin, 146g of sorbitol, and 24g of potassium hydroxide to the pressure-resistant reaction kettle, replace with nitrogen to make the oxygen content in the kettle less than 50ppm, and then add 436g of propylene oxide and 1308g of ethylene oxide at a temperature of 108-110°C Carry out a preliminary polymerization reaction, and after the reaction is completed, continue the internal pressure reaction for 3 hours to fully react the added propylene oxide and ethylene oxide, remove unreacted monomers, and obtain the intermediate polyether polyol.

[0032] Add 202g of the intermediate polyether polyol and 2.2g of the phosphazene catalyst into a pressure-resistant reactor and mix them, and replace them with nitrogen so that the oxygen content in the reactor is less than 50ppm. Bubble timer 2h. Feed 472g of propylene oxide and 1416g of ethylene oxide in proportion at a temperature of 113-117°C for copolymerization reaction, continue the internal pressure reaction f...

Embodiment 3

[0035] Add 147g of glycerin, 73g of sorbitol, and 30g of potassium hydroxide to the pressure-resistant reaction kettle, replace with nitrogen to make the oxygen content in the kettle less than 50ppm, and then add 445g of propylene oxide and 1335g of ethylene oxide at a temperature of 108-110°C Carry out a preliminary polymerization reaction, and after the reaction is completed, continue the internal pressure reaction for 3 hours to fully react the added propylene oxide and ethylene oxide, remove unreacted monomers, and obtain the intermediate polyether polyol.

[0036] Add 202g of intermediate polyether polyol and 2.4g of phosphazene catalyst into a pressure-resistant reaction kettle and mix them, replace with nitrogen to make the oxygen content in the kettle less than 50ppm, and blow with nitrogen at a temperature of 93-95°C and a vacuum of less than -0.09MPa Bubble timer 2h. Feed 508g of propylene oxide and 1522g of ethylene oxide in proportion at a temperature of 113-117°C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com