Preparation technology of fructus cannabis protein powder

A preparation process and protein powder technology are applied in the field of preparation technology of hemp protein powder, which can solve the problems of incomplete removal of oil, affecting the quality of hemp protein powder, and loss of effective protein in the hemp protein powder.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

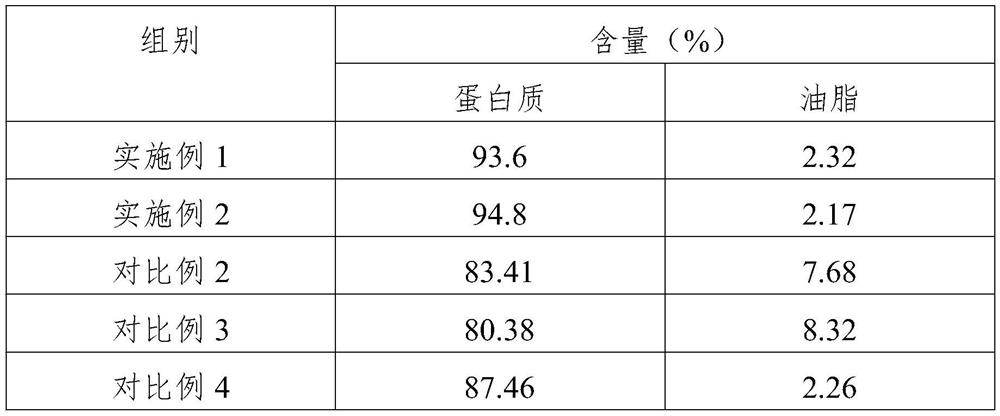

Examples

Embodiment 1

[0029] A kind of preparation technology of hemp protein powder, the preparation technology of described hemp protein powder comprises the following steps:

[0030] (1) Pretreatment of hemp seeds: select the hemp seeds to remove impurities, put them in a low-temperature environment of minus 2°C for 5 hours, take them out, dry them with hot air at 55°C, and then put them in a sheller for mechanical shelling and peeling to obtain peeled hemp seeds for later use;

[0031] (2) Hemp seed oil extraction: put the above-mentioned peeled hemp seed in a constant temperature dryer and continue drying at 45°C for 3 hours until the water content is 7%, then take out the cold air and continue drying for 3 minutes, and then put it in an oil press Carry out mechanical cold pressing at room temperature, and then separate the oil to obtain hemp seed embryo slices for later use;

[0032] (3) Preliminary extraction: add the above-mentioned hemp seed embryo slices to 75% ethanol solution and stir ...

Embodiment 2

[0039] A kind of preparation technology of hemp protein powder, the preparation technology of described hemp protein powder comprises the following steps:

[0040] (1) Pretreatment of hemp seeds: select the hemp seeds to remove impurities, put them in a low-temperature environment of minus 5°C for 5 hours, take them out, dry them with hot air at 65°C, and then put them in a shelling machine for mechanical shelling and peeling to obtain peeled hemp seeds for later use;

[0041] (2) Hemp seed oil extraction: put the above-mentioned peeled hemp seed in a constant temperature dryer and continue drying at 50°C for 3 hours until the water content is 7%, then take out the cold air and continue drying for 5 minutes, and then put it in an oil press Carry out mechanical cold pressing at room temperature, and then separate the oil to obtain hemp seed embryo slices for later use;

[0042] (3) Preliminary extraction: add the above-mentioned hemp seed germ slices to 75% ethanol solution an...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap