Bone repair 3D printing material with low barium titanate content as well as preparation method and application of bone repair 3D printing material

A 3D printing, low barium titanate technology, applied in additive processing, prosthesis, tissue regeneration, etc., can solve problems such as high barium titanate addition is not conducive to bone tissue formation, low barium titanate content cannot achieve electrical activity, etc. , to achieve good biological activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Example 1 A 3D printed scaffold for bone repair with low barium titanate content

[0048] The 3D printed scaffold for bone repair with low barium titanate content is made of the following materials and their weight percentages:

[0049] 5% of 10wt% hydroxypropyl methylcellulose aqueous solution, 1.7% of 10wt% polyethyleneimine aqueous solution, 7% of barium titanate, 63% of tricalcium phosphate, 2% of dispersant and the balance of water;

[0050] Stent design: Obtain the imaging data of the patient's bone defect, and design the shape of the defect after three-dimensional reconstruction.

[0051] Preparation:

[0052] S1. Prepare 10% w / w sodium diacetate aqueous solution, add tricalcium phosphate powder (particle size 300nm) and barium titanate (particle size 100nm) and mix evenly, then add 10% w / v hydroxypropyl methyl Aqueous cellulose solution and 10% w / v polyethyleneimine aqueous solution are mixed evenly to make the suspension into a gel to obtain a 3D printing slu...

Embodiment 2

[0056] Example 2 A 3D printed scaffold for bone repair with low barium titanate content

[0057] The 3D printed scaffold for bone repair with low barium titanate content is made of the following materials and their weight percentages:

[0058] 3.3% of 10wt% hydroxypropyl methylcellulose aqueous solution, 5% of 10wt% polyethyleneimine aqueous solution, 14% of barium titanate, 56% of tricalcium phosphate, 3% of dispersant and the balance of water;

[0059] Stent design: Obtain the imaging data of the patient's bone defect, and design the shape of the defect after three-dimensional reconstruction.

[0060] Preparation:

[0061] S1. Prepare 13% w / w sodium citrate aqueous solution, add tricalcium phosphate powder (particle size 300nm) and barium titanate (particle size 100nm) and mix evenly, then add 3.3% w / v hydroxypropyl methylcellulose in turn Mix plain aqueous solution and 5% w / v polyethyleneimine aqueous solution evenly to make the suspension into a gel, and then sonicate fo...

experiment example 1

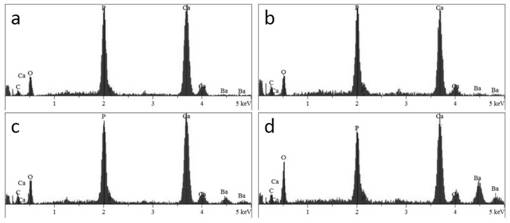

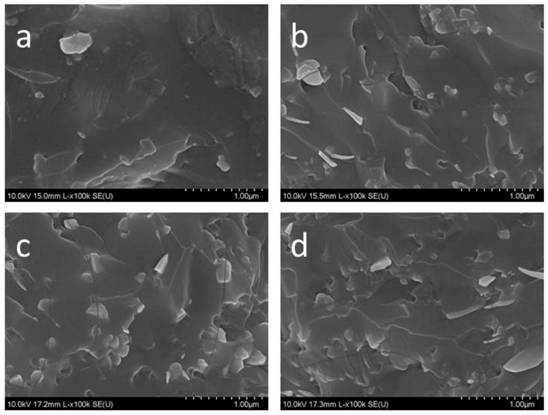

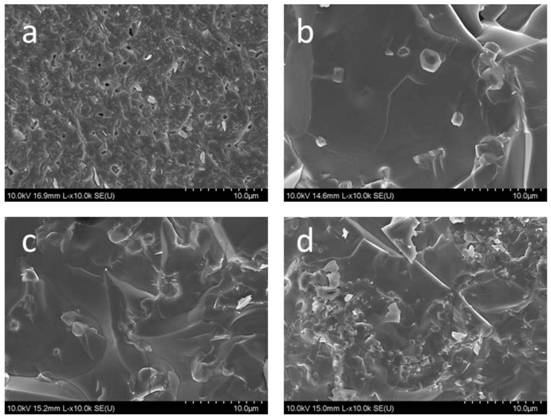

[0074] Experimental example 1 Determination of appearance and surface morphology of stents with different additions of barium titanate

[0075] With reference to the parameters and preparation method of Example 1, change the ratio of tricalcium phosphate and barium titanate (tricalcium phosphate / barium titanate are respectively 10 / 0, 9 / 1, 8 / 2, 7 / 3) to prepare a stent, And determine the appearance and surface morphology of the stent, the results can be found in figure 1 .

[0076] Depend on figure 1 It can be seen that as the content of barium titanate (BT) in the system increases, the surface of the scaffold becomes smoother and the pores become less; this is because the BT particles are smaller and can fill the voids in the TCP particles, resulting in porosity on the surface of the scaffold Less, more even. In addition, the particle size of tricalcium phosphate (TCP) particles in the calcined scaffold also tended to decrease with the increase of BT content, which may be be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com