Preparation method of non-autoclaved high-performance prefabricated pipe pile

A prefabricated pipe pile, high-performance technology, applied in the direction of manufacturing tools, solid waste management, climate sustainability, etc., can solve the problems that microbead powder cannot realize natural feeding, low activity, and feeding port blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The invention provides a method for preparing autoclaved high-performance prefabricated pipe piles, comprising the following steps:

[0046] 1) Take the following raw materials in proportion:

[0047] 280-330 parts of cement for prefabricated pipe piles,

[0048] S115 grade composite admixture 130~170 parts,

[0049] 10-13 parts of high-performance water reducer,

[0050] Machine-made sand 750-850 parts,

[0051] Crushed stone 1150~1250 parts;

[0052] 2) Mix the raw materials in step 1) with water in proportion, and stir evenly to obtain concrete. At the same time, the steel rods are straightened and cut to length, the wires are cold-drawn, and the cage knitting machine is used to make reinforced dragons, and the ends are connected The plate steel hoop is assembled;

[0053] 3) Fabric tensioning: weigh and measure the mixed concrete material according to the specification length, feed it into the pipe mold fabric, and implement prestress tension on the reinforceme...

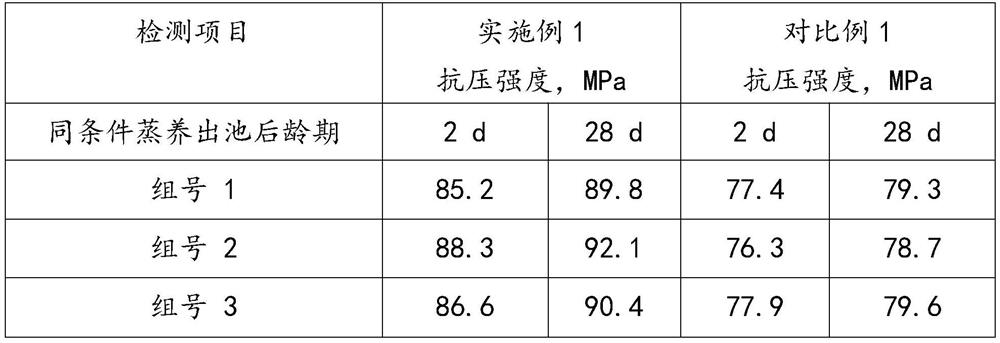

Embodiment 1

[0078] A method for preparing autoclaved high-performance prefabricated pipe piles, comprising the following steps:

[0079] 1) Take the following raw materials in proportion:

[0080] 280 parts of special cement for prefabricated pipe piles,

[0081] 150 parts of S115 grade composite admixture,

[0082] 10 parts of polycarboxylate superplasticizer,

[0083] Machine-made sand 830 parts,

[0084] 1220 pieces of gravel;

[0085] 2) Mix the raw materials in step 1) with water in proportion, and stir evenly to obtain concrete with a water-binder ratio of 0.25, and prepare reinforced dragons at the same time;

[0086] 3) Fabric tensioning: weigh and measure the mixed concrete material according to the specification length, feed it into the pipe mold fabric, and implement prestress tension on the reinforcement cage according to the design tension stress at the same time;

[0087] 4) Centrifugal forming: adopt the centrifugal system in stages, the speed of the slow cloth pipe mo...

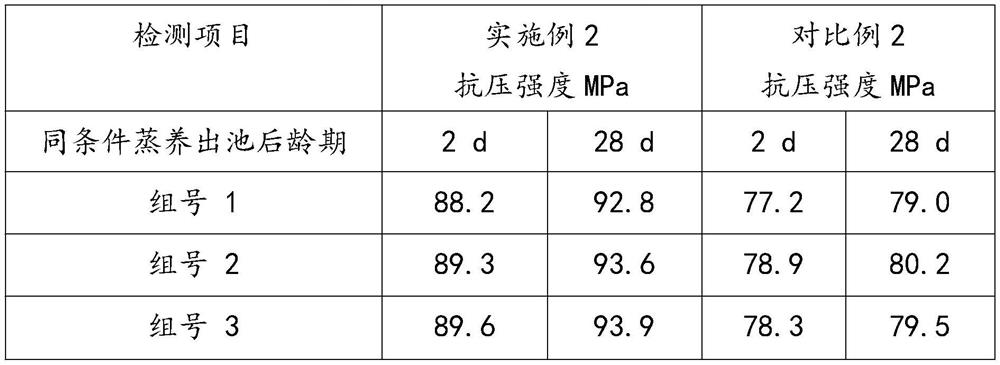

Embodiment 2

[0112] A method for preparing autoclaved high-performance prefabricated pipe piles, comprising the following steps:

[0113] 1) Take the following raw materials in proportion:

[0114] 315 parts of cement for prefabricated pipe piles,

[0115] 135 parts of S115 grade composite admixture,

[0116] Polycarboxylate superplasticizer 11 parts,

[0117] Machine-made sand 820 parts,

[0118] Crushed stone 1210 parts;

[0119] 2) Mix the raw materials in step 1) with water in proportion, and stir evenly to obtain concrete with a water-binder ratio of 0.25. At the same time, straighten the steel rods to a fixed length and cut them off, cold draw the wires, and weave them through a cage knitting machine to make steel bars Long, and assembled with end plate steel ferrule;

[0120] 3) Fabric tensioning: weigh and measure the mixed concrete material according to the specification length, feed it into the pipe mold fabric, and implement prestress tension on the reinforcement cage accor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com