A method for screening the optimal ratio of calcium carbonate from fermentation broth and its application

A technology of calcium carbonate and fermentation broth, applied in fermentation, chemical analysis by titration method, etc., can solve the problems of long time and high cost, and achieve the effect of improving biological titer, reducing process and cost, and improving adding accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

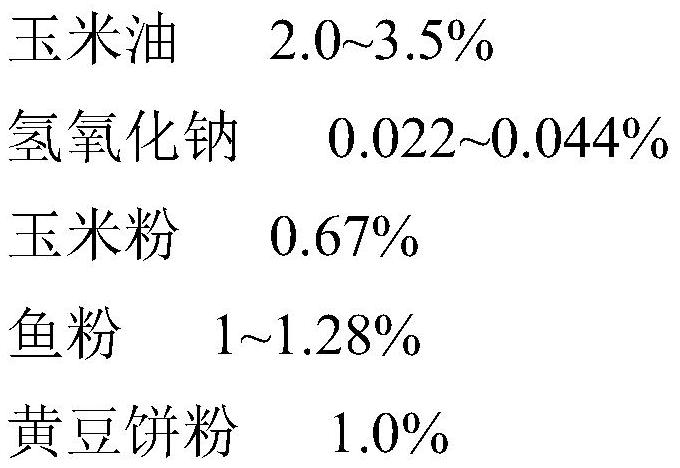

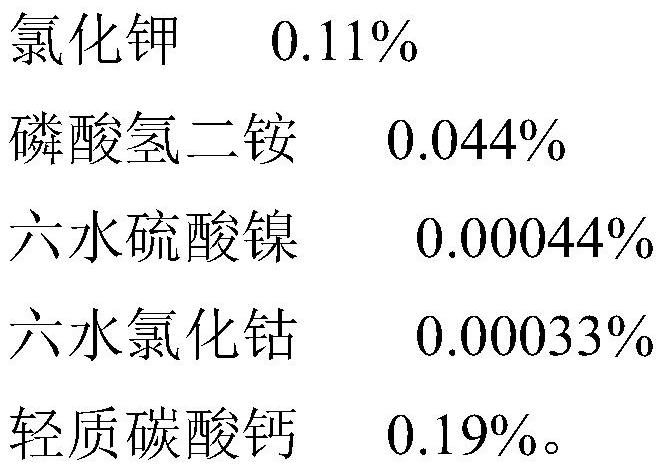

[0039] The ratio of light calcium carbonate in the test group and the control group in the guitarmycin fermentation medium was different, which were 0.26% and 0.31%, respectively. The proportions of other substances are:

[0040] raw material name Raw material ratio, % raw material name Raw material ratio, % corn starch 1 protein powder 0.21 wheat germ meal 1.15 methyl oleate 1.128 soybean meal 0.94 Potassium dihydrogen phosphate 0.073 H8 Bubble Enemy 0.019 Manganese chloride 0.052 glucose 1.50 Zinc sulfate 0.00625 n-Propanol 0.30 Soybean oil 2.4

[0041] The fermentation broth at the end of fermentation was tested for biological titer, the experimental group and the control group were 10850u / ml and 10784u / ml respectively.

Embodiment 2

[0043] The proportion of light calcium carbonate in the test group and the control group in the guitarmycin fermentation medium was different, which were 0.19% (about 1.36 times of the actual utilization) and 0.31%, respectively. The proportions of other substances are:

[0044] raw material name Raw material ratio, % raw material name Raw material ratio, % corn starch 1 protein powder 0.21 wheat germ meal 1.15 methyl oleate 1.128 soybean meal 0.94 Potassium dihydrogen phosphate 0.073 H8 Bubble Enemy 0.019 Manganese chloride 0.052 glucose 1.50 Zinc sulfate 0.00625 n-Propanol 0.30 Soybean oil 2.4

[0045] The fermentation broth at the end of the fermentation was tested for biological titer, the experimental group and the control group were 8159u / ml and 10893u / ml, respectively.

[0046] The result of embodiment 2 shows that when the ratio of light calcium carbonate is controlled at 1.36 times of the actual u...

Embodiment 3

[0048] The ratio of light calcium carbonate in the test group and the control group in the guitarmycin fermentation medium was different, which were 0.21% (about 1.46 times of the actual utilization) and 0.31%, respectively. The proportions of other substances are:

[0049] raw material name Raw material ratio, % raw material name Raw material ratio, % corn starch 1 protein powder 0.21 wheat germ meal 1.15 methyl oleate 1.128 soybean meal 0.94 Potassium dihydrogen phosphate 0.073 H8 Bubble Enemy 0.019 Manganese chloride 0.052 glucose 1.50 Zinc sulfate 0.00625 n-Propanol 0.30 Soybean oil 2.4

[0050]The fermentation broth at the end of fermentation was tested for biological titer, the experimental group and the control group were 10865u / ml and 10776u / ml respectively.

[0051] The results of Example 3 show that when the proportion of light calcium carbonate is increased to 1.46 times the actual utilization a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com