Co-HCS/CNT/S composite lithium-sulfur battery positive electrode material and preparation method thereof

A positive electrode material and composite material technology, which is applied in the field of Co-HCS/CNT/S composite lithium-sulfur battery positive electrode material and its preparation, can solve the problems of poor battery cycle life, poor rate performance, and low sulfur utilization rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

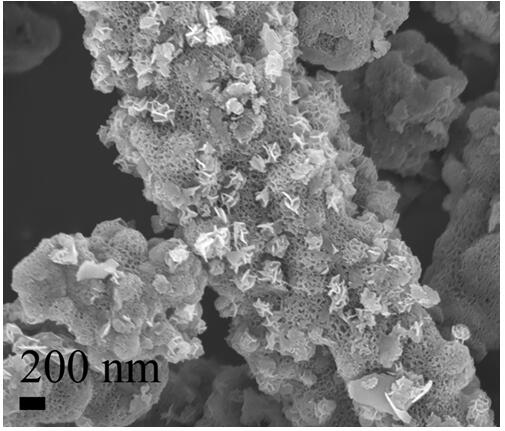

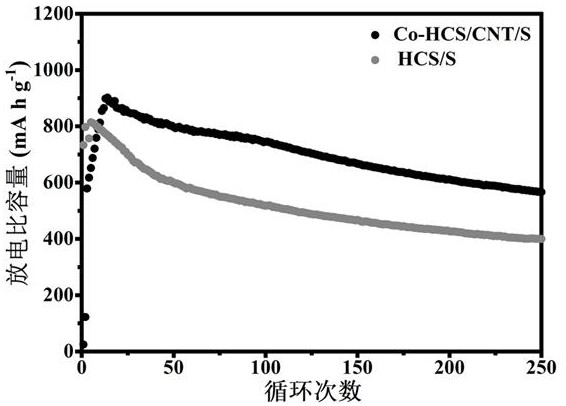

[0028] Example 1: A Co-HCS / CNT / S composite lithium-sulfur battery cathode material and its preparation method

[0029] Specifically include the following steps:

[0030] (1) Mix 3 mL tetrapropyl orthosilicate, 70 mL ethanol, 10 mL H 2 O and 3 mL, 5% (wt%) NH 3 ·H 2 O was stirred for 15 min; 0.4 g resorcinol, 0.56 ml, 37% wt% formaldehyde, 0.1 g PPy, 0.2 g Co(NO 3 ) 2 ·6H 2 O, stirred for 24 hours; centrifuged, washed, and dried.

[0031] The synthesis method of PPy is as follows:

[0032] 0.1 g methyl orange, 1.96 g FeCl 3 , 150 mL deionized water, 500 μL pyrrole monomer, magnetically stirred at room temperature for 24 h. Centrifuge, wash, and dry.

[0033] (2) Annealing in an argon atmosphere at 700°C for 5 hours to obtain SiO 2 @Co-HCS / CNT.

[0034] (3) SiO 2 @Co-HCS / CNT and 2 mol / L sodium hydroxide solution were mixed and allowed to stand for 36 hours, then dried after centrifugation. Co-HCS / CNT is obtained.

[0035] (4) Mix sulfur powder and Co-HCS / CNT at a m...

Embodiment 2

[0050] Example 2: A Co-HCS / CNT / S composite lithium-sulfur battery cathode material and its preparation method

[0051] Specifically include the following steps:

[0052] (1) Mix 2 mL tetrapropyl orthosilicate, 46.6 mL ethanol, 6.66 mL H 2 O and 2 mL, 5% wt% NH 3 ·H 2 O was stirred for 15 min; added 0.13 g resorcinol, 0.37 mL, 37% wt% formaldehyde, 0.2 g PPy, 0.13 g Co(NO 3 ) 2 ·6H 2 O, stirred for 24 hours; centrifuged, washed, and dried.

[0053] The synthesis method of PPy is as follows:

[0054] 0.1 g methyl orange, 1.96 g FeCl 3 , 150 mL deionized water, 500 μL pyrrole monomer magnetic stirring at room temperature for 24 hours; centrifuge, wash and dry.

[0055] (2) Annealing in an argon atmosphere at 700°C for 5 hours to obtain SiO 2 @Co-HCS / CNT.

[0056] (3) SiO2@Co-HCS / CNT and 2 moL / L sodium hydroxide solution were mixed and allowed to stand for 36 hours, then dried after centrifugation.

[0057] (4) Mix sulfur powder with Co-HCS / CNT at a mass ratio of 7:3. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com