Environment-friendly plastic adhesive and preparation method thereof

A technology of environmentally friendly plastics and adhesives, applied in the direction of adhesive types, ester copolymer adhesives, polymer adhesive additives, etc., to achieve the effects of low equipment dependence, high bonding strength, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

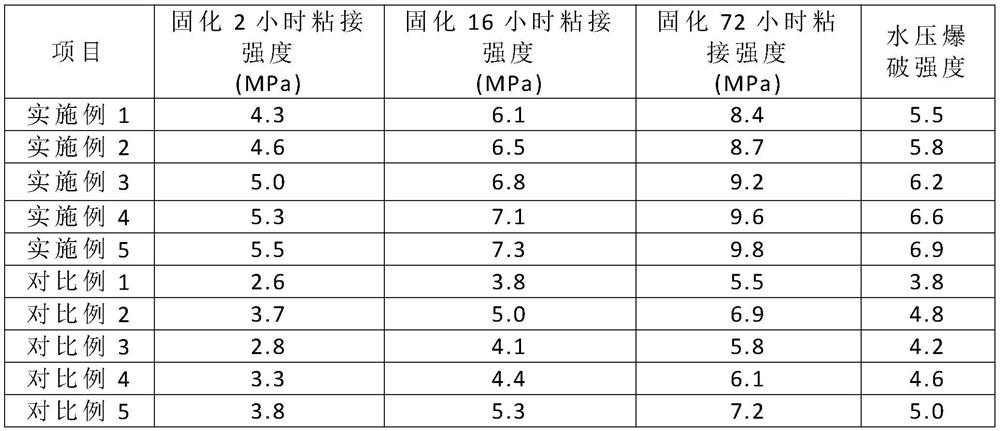

Examples

Embodiment 1

[0027] A kind of environment-friendly plastic adhesive is characterized in that, comprises following each component by weight: 5 parts of rosin-based hyperbranched epoxy resins, 3 parts of epoxidized SBS, 4 parts of fillers, allyl furoate / N-vinylcaprolactam / N-trimethylolmethacrylamide / N-(4-cyano-3-trifluoromethylphenyl)methacrylamide / trifluoroethyl methacrylate copolymer 12 parts , 3 parts of isocyanate group ionized modified 2,5-bis(diethylamino)phenyl-1,3,4-oxadiazole, 0 parts of dibutyltin dilaurate, 70 parts of mixed solvent; the mixed solvent is Tetrahydrofuran, methyl ethyl ketone, butyl acetate, and N,N-dimethylformamide in a mass ratio of 1:1:0.5:0.8.

[0028] The preparation method of the isocyanate group ionization modified 2,5-bis(diethylamino)phenyl-1,3,4-oxadiazole comprises the following steps: 2,5-bis(diethylamino) Phenyl-1,3,4-oxadiazole and chloroethyl isocyanate were added to dimethyl sulfoxide, stirred and reacted at 40°C for 4 hours, and then the solvent ...

Embodiment 2

[0033] A kind of environment-friendly plastic adhesive is characterized in that, comprises following each component by weight: 6 parts of rosin-based hyperbranched epoxy resins, 3.5 parts of epoxidized SBS, 4.5 parts of fillers, allyl furoate / N-vinylcaprolactam / N-trimethylolmethacrylamide / N-(4-cyano-3-trifluoromethylphenyl)methacrylamide / trifluoroethyl methacrylate copolymer 14 parts , 3.5 parts of isocyanate group ionized modified 2,5-bis(diethylamino)phenyl-1,3,4-oxadiazole, 0.1 part of dibutyltin dilaurate, 73 parts of mixed solvent; the mixed solvent is Tetrahydrofuran, methyl ethyl ketone, butyl acetate, and N,N-dimethylformamide are in a mass ratio of 1.3:1:0.6:0.9.

[0034] The preparation method of the isocyanate group ionization modified 2,5-bis(diethylamino)phenyl-1,3,4-oxadiazole comprises the following steps: 2,5-bis(diethylamino) Phenyl-1,3,4-oxadiazole and chloroethyl isocyanate were added to dimethyl sulfoxide, stirred and reacted at 45°C for 4.5 hours, and th...

Embodiment 3

[0039] A kind of environment-friendly plastic adhesive is characterized in that, comprises the following components by weight: 6.5 parts of rosin-based hyperbranched epoxy resins, 4 parts of epoxidized SBS, 5.5 parts of fillers, allyl furoate / N-vinylcaprolactam / N-trimethylolmethacrylamide / N-(4-cyano-3-trifluoromethylphenyl)methacrylamide / trifluoroethyl methacrylate copolymer 16 parts , 4 parts of isocyanate group ionized modified 2,5-bis(diethylamino)phenyl-1,3,4-oxadiazole, 0.15 parts of dibutyltin dilaurate, 75 parts of mixed solvent; the mixed solvent is Tetrahydrofuran, methyl ethyl ketone, butyl acetate, and N,N-dimethylformamide are in a mass ratio of 1.5:1:0.65:1.

[0040] The preparation method of the isocyanate group ionization modified 2,5-bis(diethylamino)phenyl-1,3,4-oxadiazole comprises the following steps: 2,5-bis(diethylamino) Phenyl-1,3,4-oxadiazole and chloroethyl isocyanate were added to dimethyl sulfoxide, stirred and reacted at 50°C for 5 hours, and then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com