Cooperative treatment method for waste incineration fly ash and copper-containing sludge

A technology for waste incineration fly ash and co-processing, applied in the direction of improving process efficiency, can solve the problems of ineffective recovery of valuable components, difficulty in enrichment, and damage to the surrounding ecological environment, and achieve environmentally friendly production and applicability. Strong, anti-corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

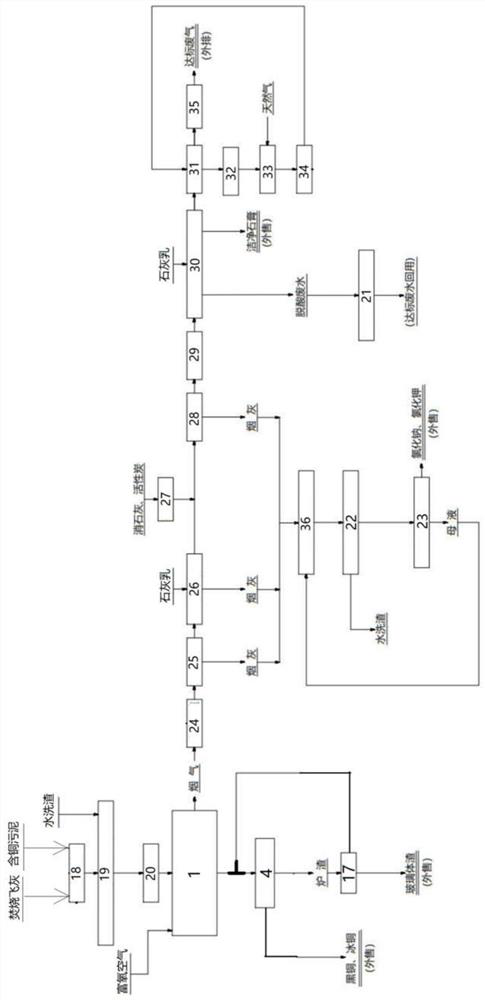

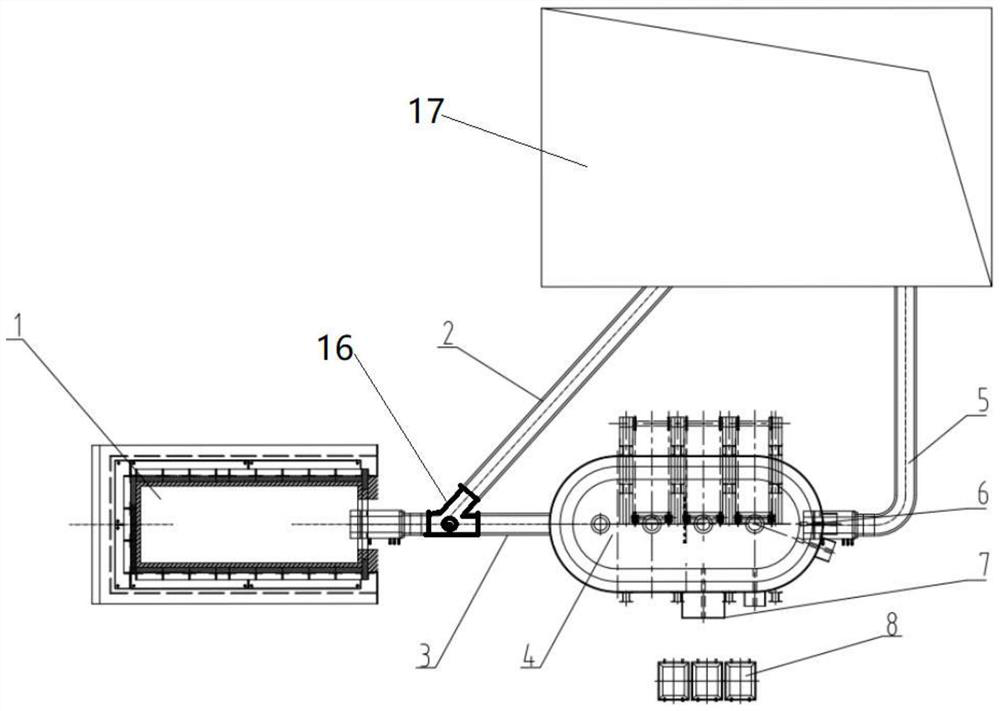

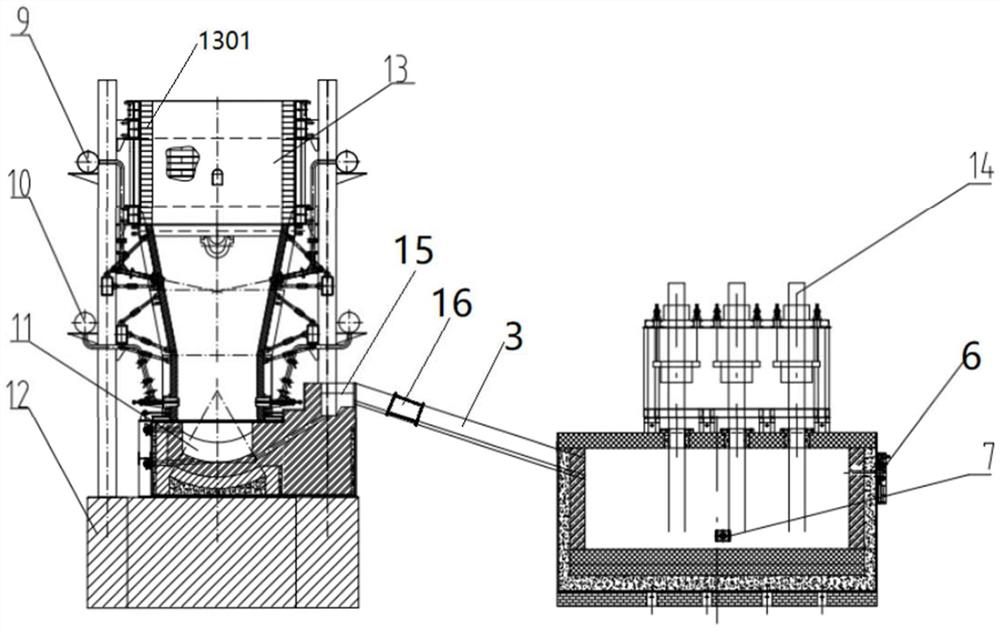

[0092] The co-processing method of the waste incineration fly ash and copper-containing sludge of the present embodiment comprises the following steps:

[0093] S1. Mix the waste incineration fly ash and copper-containing sludge evenly at a mass ratio of 5:1, and make pellets to obtain pellets (high-chloride, low-copper-nickel mixture);

[0094] Among them, the waste incineration fly ash contains 18wt% of chlorine, 3wt% of water, and the content of copper and nickel is less than 1wt%; the copper-containing sludge contains 3.4wt% of copper, 1.2wt% of nickel, 60wt% of water, and the chlorine content is <1wt% %;

[0095] S2, mixing the pellets, flux and fuel obtained in S1 to obtain a mixture;

[0096] Wherein, in the mixture, SiO 2 , The mass ratio of Fe is 0.7:1, SiO 2 , the mass ratio of CaO is 0.9:1; every 1kg of pellets is mixed with fuel with 1600kcal of heat; the amount of coke added is 21wt% of the pellets;

[0097] S3. Smelting the mixture obtained in S2 to obtain mo...

Embodiment 2

[0104] The co-processing method of the waste incineration fly ash and copper-containing sludge of the present embodiment comprises the following steps:

[0105] S1. Mix the waste incineration fly ash and copper-containing sludge evenly at a mass ratio of 3:1, and make pellets to obtain pellets (high-chloride, low-copper-nickel mixture);

[0106] Among them, the waste incineration fly ash contains 21wt% of chlorine, 2wt% of water, and the content of copper and nickel is less than 1wt%; the copper-containing sludge contains 2.7wt% of copper, 0.6wt% of nickel, 50wt% of water, and the chlorine content is <1wt% %;

[0107] S2, mixing the pellets, flux and fuel obtained in S1 to obtain a mixture;

[0108] Wherein, in the mixture, SiO 2 , The mass ratio of Fe is 0.75:1, SiO 2 1. The mass ratio of CaO is 0.85:1; every 1kg of pellets is mixed with fuel with 1200kcal of heat; the fuel contains coke; the amount of coke added is 21wt% of the pellets;

[0109] S3. Smelting the mixture ...

Embodiment 3

[0116] The co-processing method of the waste incineration fly ash and copper-containing sludge of the present embodiment comprises the following steps:

[0117] S1. Mix the waste incineration fly ash and copper-containing sludge evenly at a mass ratio of 2:5, and make pellets to obtain pellets (low-chlorine, high-copper-nickel mixture);

[0118] Among them, waste incineration fly ash contains 6wt% chlorine, 2wt% water, and both copper and nickel contents are less than 1wt%; copper-containing sludge contains 4.1wt% copper, 1.3wt% nickel, 30wt% water, and chlorine content <1wt% %;

[0119] S2, mixing the pellets, flux and fuel obtained in S1 to obtain a mixture;

[0120] Wherein, in the mixture, SiO 2 , The mass ratio of Fe is 0.8:1, SiO 2 1. The mass ratio of CaO is 1:1; every 1kg of pellets is mixed with fuel with 1400kcal of heat; the fuel contains coke; the amount of coke added is 21wt% of the pellets;

[0121] S3. Smelting the mixture obtained in S2 to obtain molten sla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com