Enol-ketone type covalent organic framework/graphite phase carbon nitride composite photocatalyst as well as preparation method and application thereof

A technology of graphite phase carbon nitride and covalent organic framework, applied in organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of high raw material costs and limited nitrogen Carbon-based semiconductor heterojunction application range, low specific surface area, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

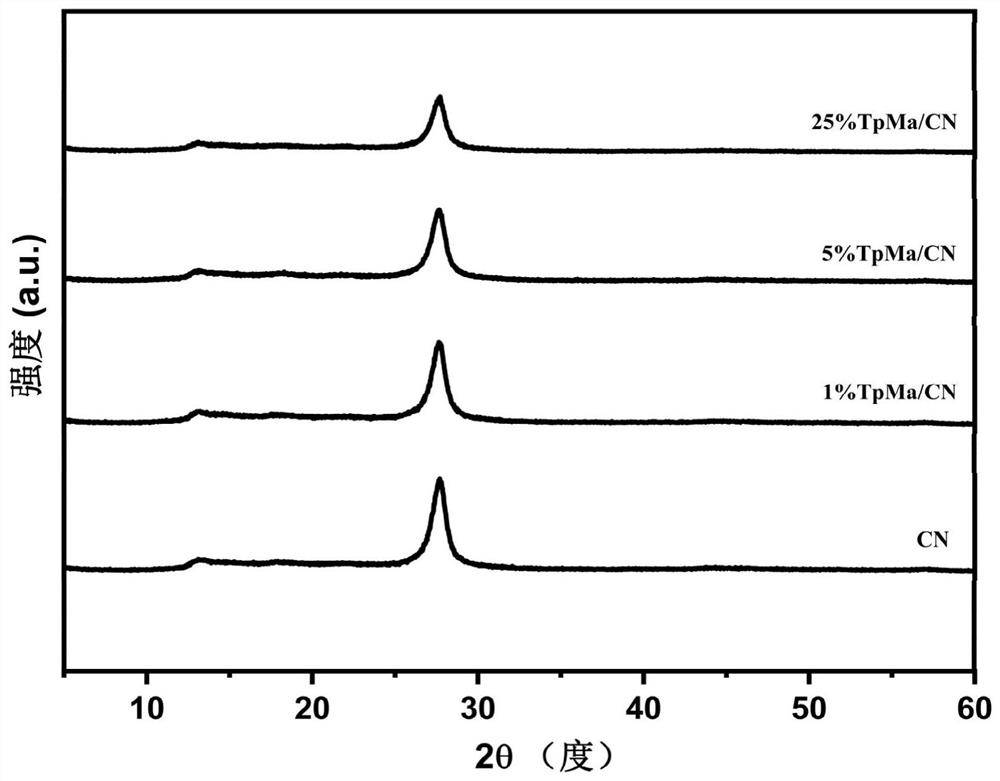

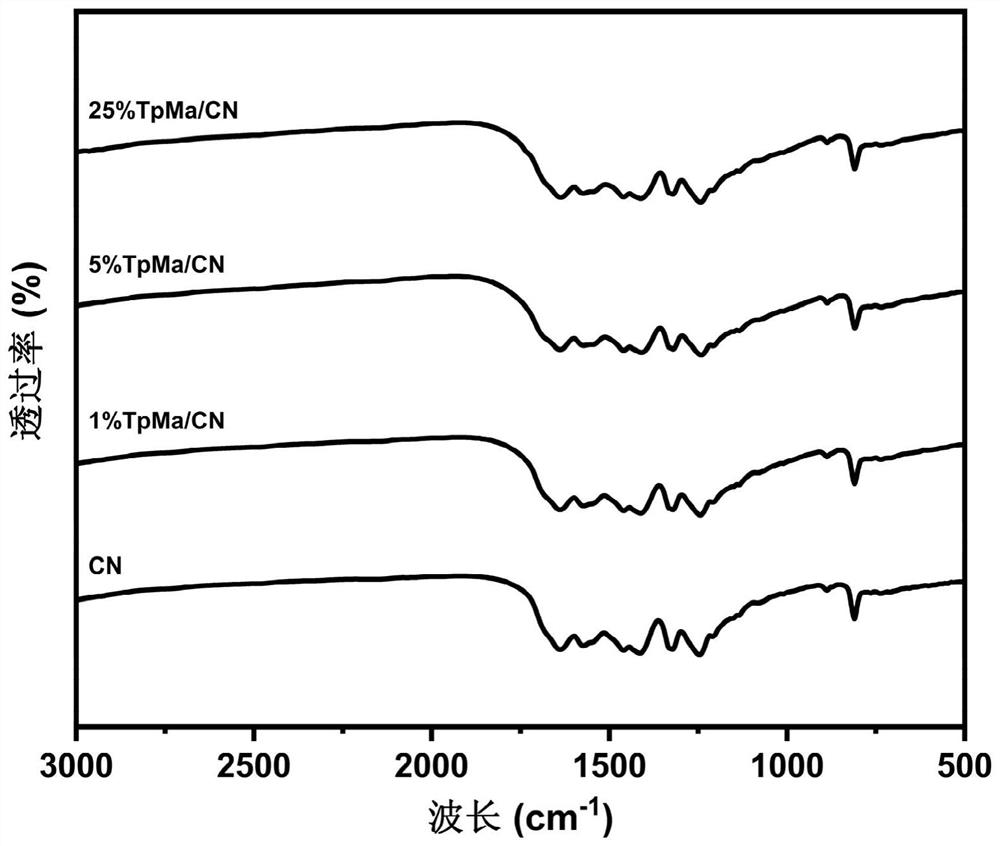

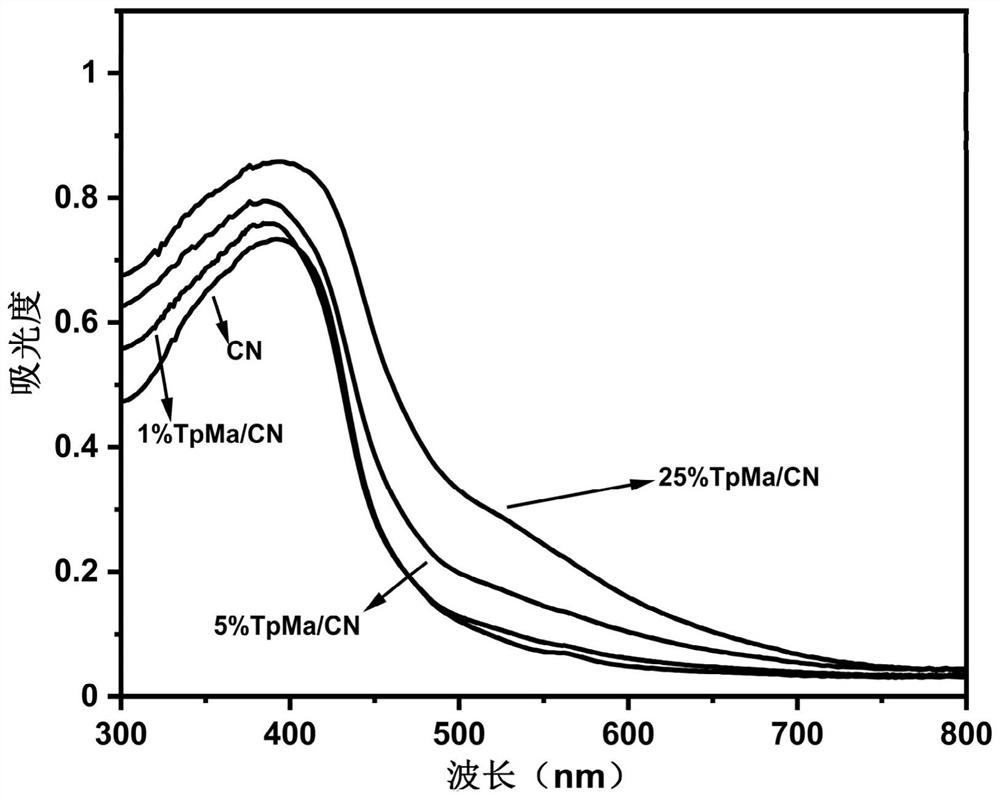

[0037] A kind of enol-ketone covalent organic framework / graphite carbon nitride composite photocatalyst, including graphite phase carbon nitride and enol-ketone covalent organic framework, enol-ketone covalent organic framework supported on graphite Phase carbon nitride, wherein the mass ratio of graphite phase carbon nitride and enol-ketone covalent organic framework is 1:0.01. Graphite phase carbon nitride is lamellar. The enol-ketone covalent organic framework is fibrous rod-shaped with a diameter of 116nm.

[0038] A preparation method of the enol-ketone covalent organic framework / graphite phase carbon nitride composite photocatalyst in the above-mentioned present embodiment specifically comprises the following steps:

[0039] (1) Put 8g of melamine into a crucible, place it in a muffle furnace, heat it up to 550°C at a heating rate of 2.3°C / min, and keep it at 550°C for 4 hours, take it out after natural cooling, and grind it with a mortar , to obtain a yellow powder sa...

Embodiment 2

[0043] A kind of enol-ketone type covalent organic framework / graphite phase carbon nitride composite photocatalyst, basically the same as embodiment 1, the difference is only: graphite phase carbon nitride and enol-ketone type covalent organic framework in embodiment 2 The mass ratio of the skeleton is 1:0.05.

[0044] A preparation method of the enol-ketone covalent organic framework / graphite phase carbon nitride composite photocatalyst in the above-mentioned embodiment is basically the same as in Example 1, the only difference being that in Example 2 the enol-ketone covalent The dosage of the valent organic framework is 25 mg.

[0045] The enol-ketone covalent organic framework / graphite phase carbon nitride composite photocatalyst prepared in Example 2 is named 5% TpMa / CN.

Embodiment 3

[0047] A kind of enol-ketone type covalent organic framework / graphite phase carbon nitride composite photocatalyst, basically the same as embodiment 1, the difference is only: in embodiment 3, graphite phase carbon nitride and enol-ketone type covalent organic framework The mass ratio of the skeleton is 1:0.25.

[0048] A preparation method of the enol-ketone covalent organic framework / graphite phase carbon nitride composite photocatalyst in the above-mentioned embodiment is basically the same as in Example 1, the only difference being that in Example 3 the enol-ketone covalent The dosage of the valent organic framework is 125 mg.

[0049] The enol-ketone covalent organic framework / graphite phase carbon nitride composite photocatalyst prepared in Example 3 is named 25% TpMa / CN.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com