Preparation method of boron carbide micro-nano mixed powder for hot pressed sintering

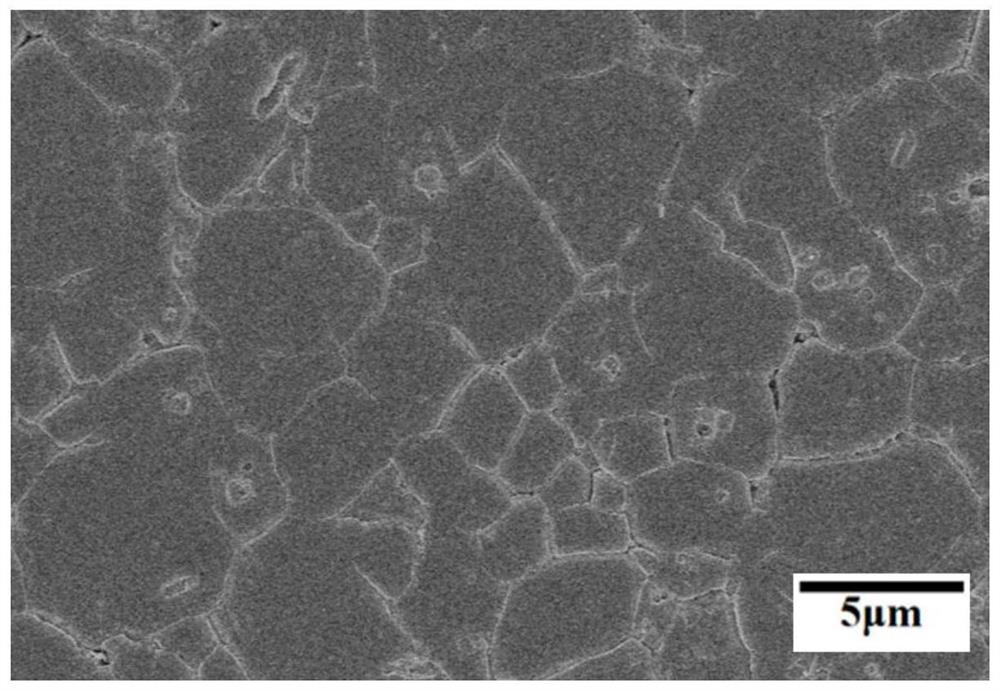

A technology of micro-nano mixing and hot-press sintering, which is applied in the field of preparation of boron carbide micro-nano mixed powder for hot-press sintering, which can solve the problems of high densification and fine grain size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0016] Embodiment 1: In this embodiment, a method for preparing boron carbide micro-nano mixed powder for hot pressing sintering is completed according to the following steps:

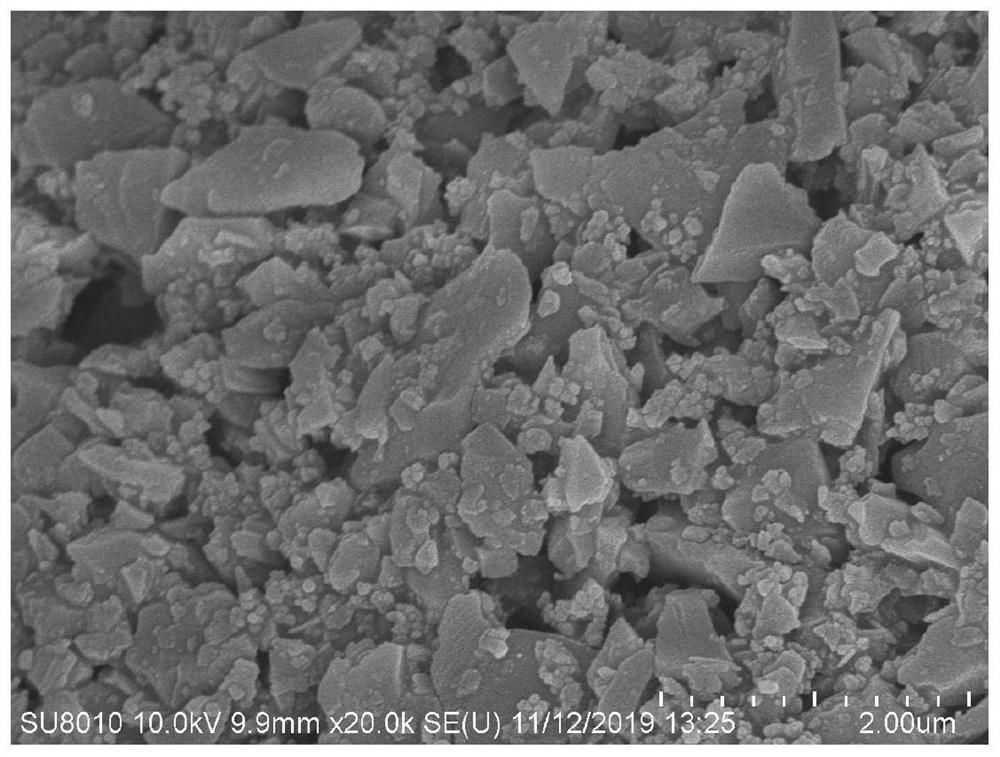

[0017] 1. Dispersion of raw materials: Place nano boron carbide powder and micron boron carbide powder in deionized water containing dispersant to disperse evenly to obtain nano boron carbide slurry and micron boron carbide slurry; the particle size of nano boron carbide powder is 20nm ~300nm, the particle size of micron boron carbide powder is 1μm~10μm; the mass ratio of nanometer boron carbide powder, micron boron carbide powder and deionized water is 1:(0.5~5);

[0018] 2. Raw material mixing: mix the dispersed nano boron carbide slurry and micron boron carbide slurry evenly in step 1; wherein the mass ratio of nano boron carbide powder and micron boron carbide powder is 1:(1~50);

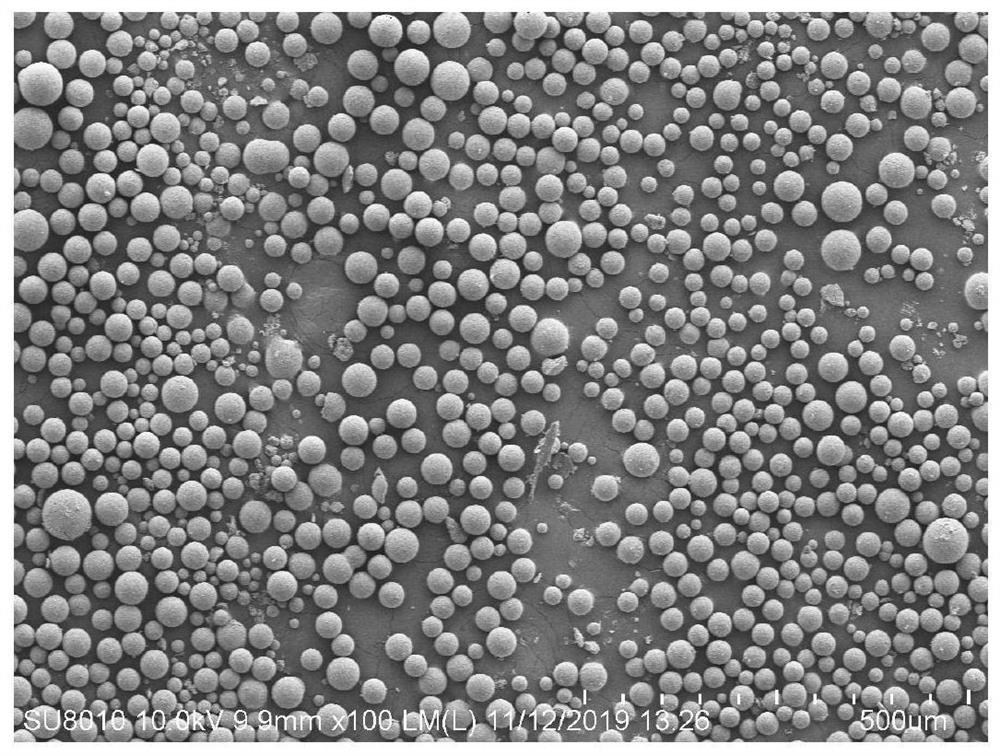

[0019] 3. Drying of raw materials: The boron carbide micro-nano mixed slurry is granulated into round particles by spr...

specific Embodiment approach 2

[0020] Embodiment 2: This embodiment differs from Embodiment 1 in that the mass ratios of nano boron carbide powder, micron boron carbide powder and dispersant are all 1:0.001-0.03. Others are the same as the first embodiment.

specific Embodiment approach 3

[0021] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the dispersant described in step one is tetramethylammonium hydroxide, polyvinyl pyrrolidone, sodium hydroxymethyl cellulose, polyvinylpyrrolidone Sodium acrylate or polyethylene glycol. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com