Hemostatic material

A technology of hemostatic materials and substrates, applied in the field of hemostatic materials, can solve the problem of small promotion of platelet aggregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

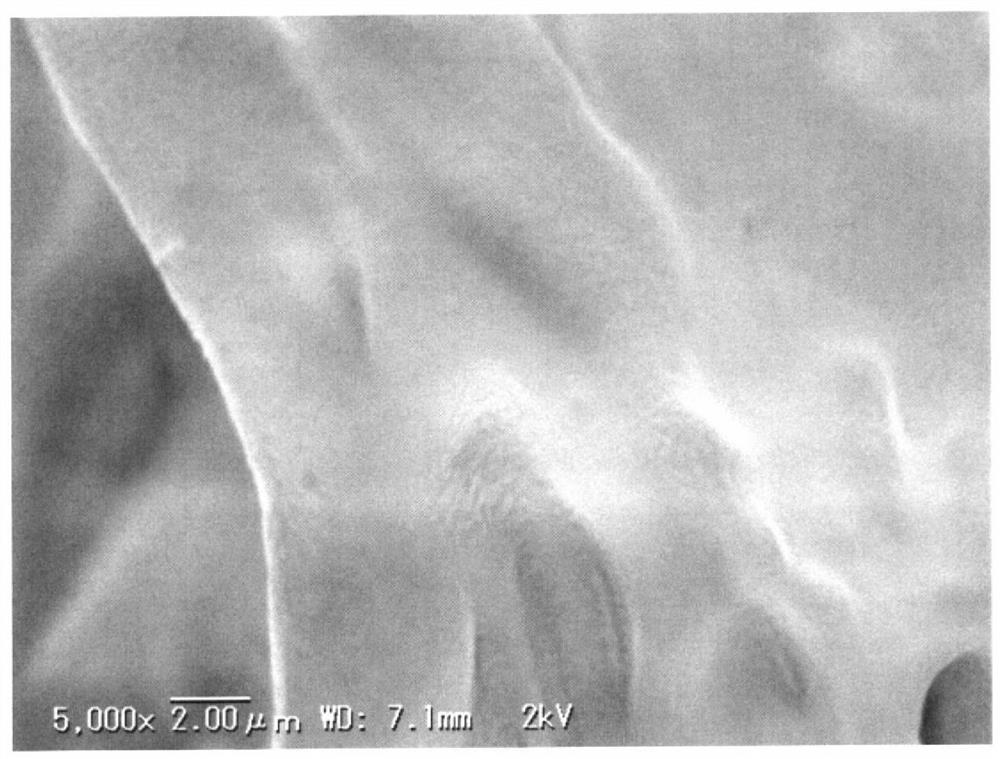

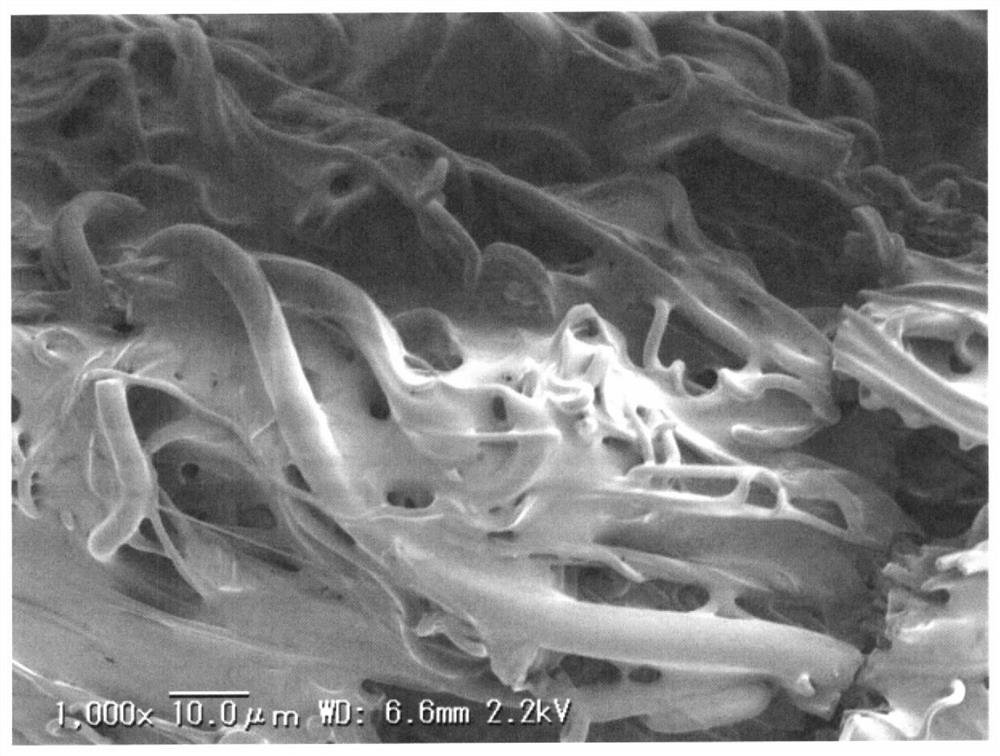

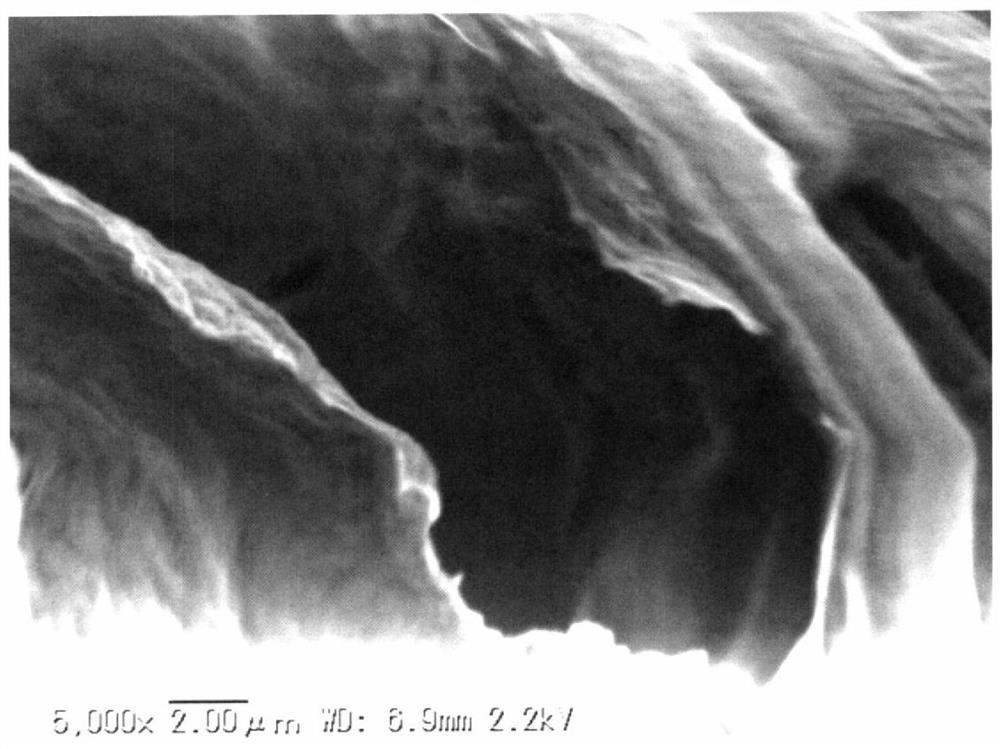

Image

Examples

Embodiment 1~10 and comparative example 1

[0754] (1) Preparation of liposomes

[0755] Follow the steps below to prepare liposomes. At this time, the carboxylic acid-type lipid obtained by the above synthesis method was used together with the following lipids (commercially available). In addition, cholesterol may be described as "Chol" below.

[0756] DPPC (1,2-dipalmitoyl-sn-glycerol-3-phosphatidylcholine, manufactured by Nippon Seika Co., Ltd.)

[0757] DPPG (1,2-dipalmitoyl-sn-glycerol-3-phosphatidylglycerol, manufactured by NOF Sangyo Co., Ltd.)

[0758] DPPS (1,2-dipalmitoyl-sn-glycerol-3-phosphatidylserine, manufactured by NOF Sangyo Co., Ltd.)

[0759] Cholesterol (manufactured by Nippon Seika Co., Ltd.)

[0760] PEG-DSPE (1,2-distearoyl-sn-glycerol-3-phosphatidylethanolamine-N-[monomethoxypoly(ethylene glycol)], manufactured by NOF Corporation)

[0761] Lipids were mixed at the molar ratios shown in Table 1 to obtain lipid mixtures. The obtained lipid mixture was dissolved in tert-butanol, and the obta...

Embodiment 11 and 12

[0815] (1) Getting started with phospholipids

[0816] DPPA sodium salt (1,2-dipalmitoyl-sn-glycero-3-phosphatidic acid sodium salt, 1,2-Dipalmitoyl-sn-glycero-3-phosphatidic acid, sodium salt) was purchased from NOF Sangyo Co., Ltd. ( COATSOME MA-6060LS). The -O-P(=O)(-OH)(-O - Na + ) into -P(=O)(-OH)(-OH) to produce acid-type DPPA. It should be noted that the solubility of anionic DPPA in tert-butanol is higher than that of DPPA sodium salt.

[0817] After mixing 150 mg of DPPA sodium salt and 15 mL of a mixed solution of chloroform and methanol (volume of chloroform:volume of methanol=6:4), 56.0 μL of 4M hydrochloric acid was added, and ultrasonic treatment was performed at 50° C. for 30 minutes. After sonication, the solvent was evaporated, 5 mL of tert-butanol was added, and NaCl was removed by filtration with a filter to obtain acid-form DPPA. It should be noted that the acid form of DPPA is obtained by reacting DPPA sodium salt with equimolar hydrochloric acid.

...

Embodiment 13~16

[0825] (1) Lipid synthesis

[0826] DHSG was synthesized in the same manner as above, and Asp-DHSG, Glu-DHSG, and AG-DHSG were synthesized in the same manner as above using the synthesized DHSG.

[0827] (2) Production of hemostatic materials

[0828] DHSG, Asp-DHSG, Glu-DHSG, and AG-DHSG were prepared in the same manner as above. In the same manner as above, a base material composite with a cellulose sponge and a poly-L-lactic acid resin fiber sheet formed on the cellulose sponge was produced, and the produced base material composite was punched out with a metal punch to obtain a diameter It is a 13mm cylindrical substrate complex. 66.7 μL each of 30 mg / mL DHSG, Asp-DHSG, Glu-DHSG, and AG-DHSG tert-butanol solutions were sprayed on the substrate part (fiber sheet part) of the obtained cylindrical substrate composite, and dried, thereby Make hemostatic material. In Example 13, a tert-butanol solution of DHSG was used to make a hemostatic material (hereinafter referred to a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dimension diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com