Ink, quantum dot film and quantum dot light emitting diode

A technology of quantum dots and inks, which is applied in the fields of inks, quantum dot films and quantum dot light-emitting diodes, and can solve the problems of uneven film formation of quantum dots and poor dispersion of quantum dot inks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

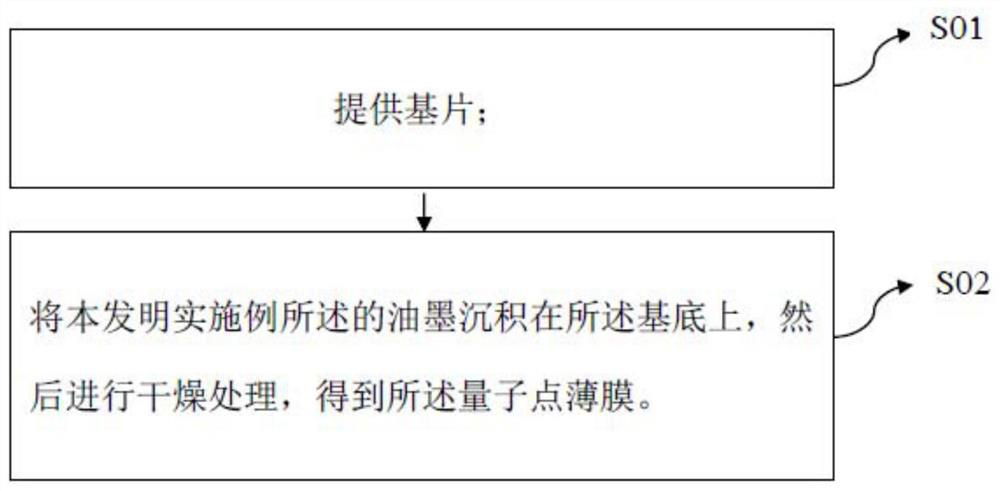

[0052] Correspondingly, an embodiment of the present invention provides a method for preparing a quantum dot film, such as figure 1 shown, including the following steps:

[0053] S01: Provide the substrate;

[0054] S02: Deposit the ink described in the embodiment of the present invention on the substrate, and then perform drying treatment to obtain the quantum dot film.

[0055] Specifically, the method of ink configuration includes: firstly dissolving the functional block copolymer in one or several organic solvents according to a certain proportion to obtain a solvent with suitable viscosity, boiling point and surface tension; then dissolving the quantum dots according to a predetermined proportion The quantum dot ink is obtained by dissolving in the above-mentioned modified solvent.

[0056] Specifically, the method for depositing the ink on the base sheet is an inkjet printing method, including: inkjet printing the quantum dot light-emitting layer film by selecting a su...

Embodiment 1

[0064] A method for preparing an ink and a method for printing and forming a film, comprising the steps of:

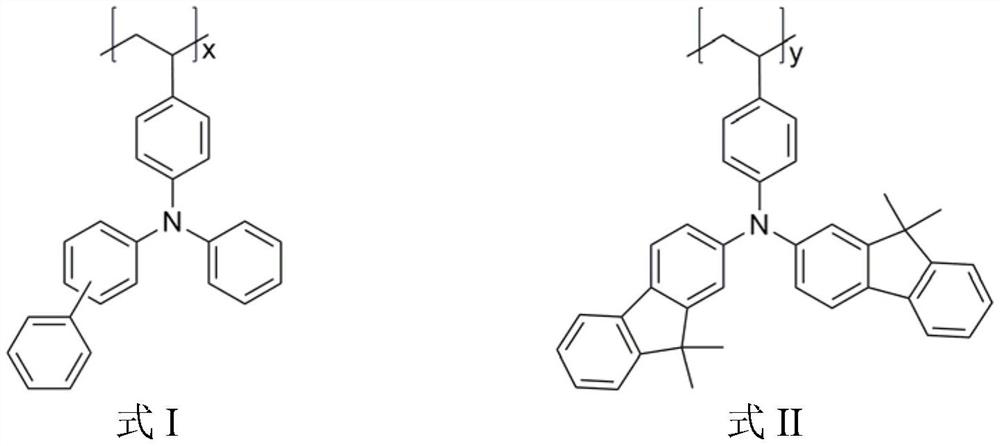

[0065] (1) Functional block polymer modifier: synthesis of mercapto-polystyrene-A-R

[0066] The functional monomer N-phenyl-N-biphenyl-p-vinylaniline of the above-mentioned type I block chain 5g, the free radical initiator azobisisobutylcyanide (AIBN) 5mg, phenylethyl dithiobenzoate 60 mg of the base ester was mixed and dissolved in 50 mL of tetrahydrofuran, and the oxygen in the mixture was removed by vacuum-liquid nitrogen defoaming several times, filled with nitrogen, heated to 50 degrees Celsius, and polymerized for 48 hours. The reactant mixture was cooled in liquid nitrogen for a few seconds to terminate the chain transfer reaction, and then precipitated with n-hexane to obtain a total of 4.0 g of the first functionalized polymer chain macromolecule RAFT reagent.

[0067] Dissolve 3 g of the above-mentioned first section of functionalized polymer chain macromol...

Embodiment 2

[0074] A method for preparing an ink and a method for printing and forming a film, comprising the steps of:

[0075] (1) Functional block polymer modifier: synthesis of mercapto-polystyrene-A-R

[0076] The functional monomer N-phenyl-N-biphenyl-p-vinylaniline of the above-mentioned type I block chain 3g, the free radical initiator azobisisobutylcyanide (AIBN) 3mg, phenylethyl dithiobenzoate 60 mg of the base ester was mixed and dissolved in 50 mL of tetrahydrofuran, and the oxygen in the mixture was removed by vacuum-liquid nitrogen defoaming several times, filled with nitrogen, heated to 50 degrees Celsius, and polymerized for 48 hours. Then add 2 g of N,N-bis-p-(9,9-dimethylfluorenyl)phenyl-p-vinylaniline, a type II block chain functional monomer, and remove the mixture by vacuum-liquid nitrogen defoaming several times. The oxygen in it is filled with nitrogen and then heated to 50 degrees Celsius to polymerize for 48 hours. The reactant mixture was cooled in liquid nitro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com