Epitaxial integrated dielectric film distributed bragg reflector (DBR) external cavity surface emitting laser

A technology of emitting lasers and integrated media, applied in lasers, laser parts, semiconductor lasers, etc., can solve the problems of unstable polarization, short photon life, hindering applications, etc., achieve stable polarization voltage, narrow line width, and increase high reflection characteristics , Increase the effect of the original cavity length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

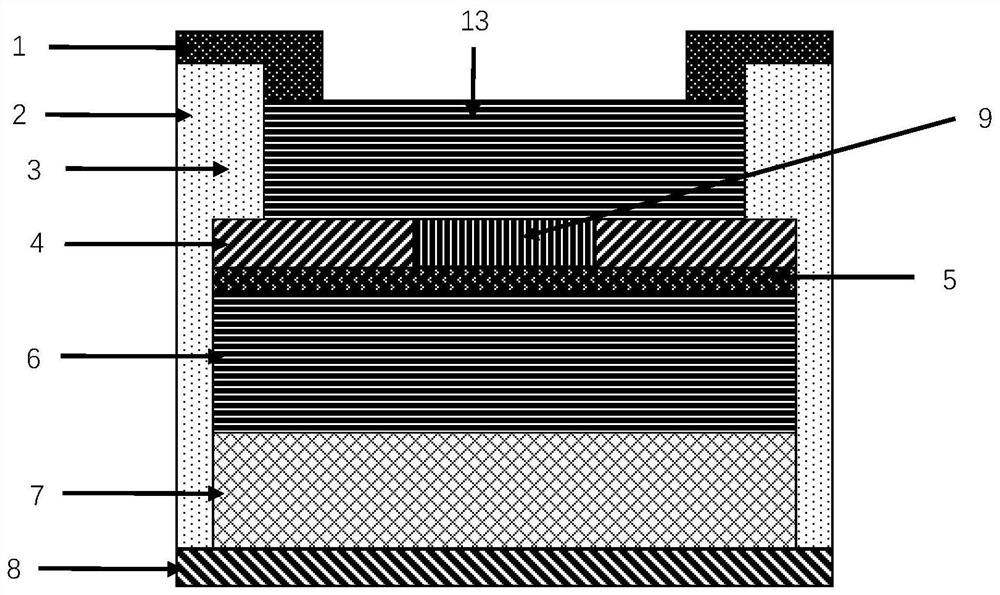

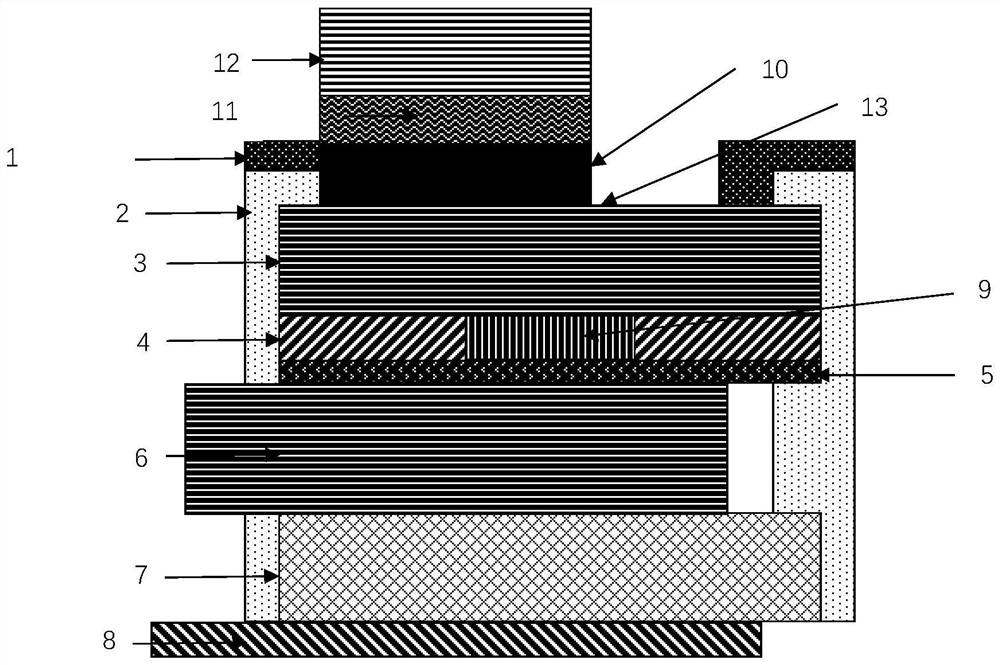

[0014] Such as figure 1 , 2 As shown, the 850nm epitaxial wafer is grown by MOCVD, silicon oxide is deposited by ICPCVD, the mesa pattern is etched by photolithography, the mesa is etched by ICP, and the oxidation limiting layer (4) with high aluminum composition is exposed, and the current limiting layer is formed by wet oxidation. Oxidation holes (9), use ICPCVD to grow passivation layer (2), etch light exit holes (13) by photolithography, make P-type electrodes (1) by thermal evaporation and stripping, and make N-type electrodes by magnetron sputtering ( 8), to obtain a common oxide vertical cavity surface emitting laser (attached figure 1 ); by inductively coupled plasma-enhanced chemical vapor deposition and stripping, the dielectric layer is deposited to a common vertical cavity surface emitting laser device to form a phase matching layer (10), a cavity length matching layer (11) and a dielectric film distributed Bragg reflection mirror (12), to obtain an epitaxially i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com