A kind of carbon/carbon composite material crucible with composite ceramic layer and preparation method thereof

A technology of carbon composite materials and composite ceramics, which is applied in the field of thermal field components for single crystal silicon drawing furnaces, can solve the problems of softening and deformation of quartz crucibles, high cost of single crystal silicon, and high cost of raw materials, so as to reduce thermal expansion coefficient and reduce raw materials The effect of simple cost and preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

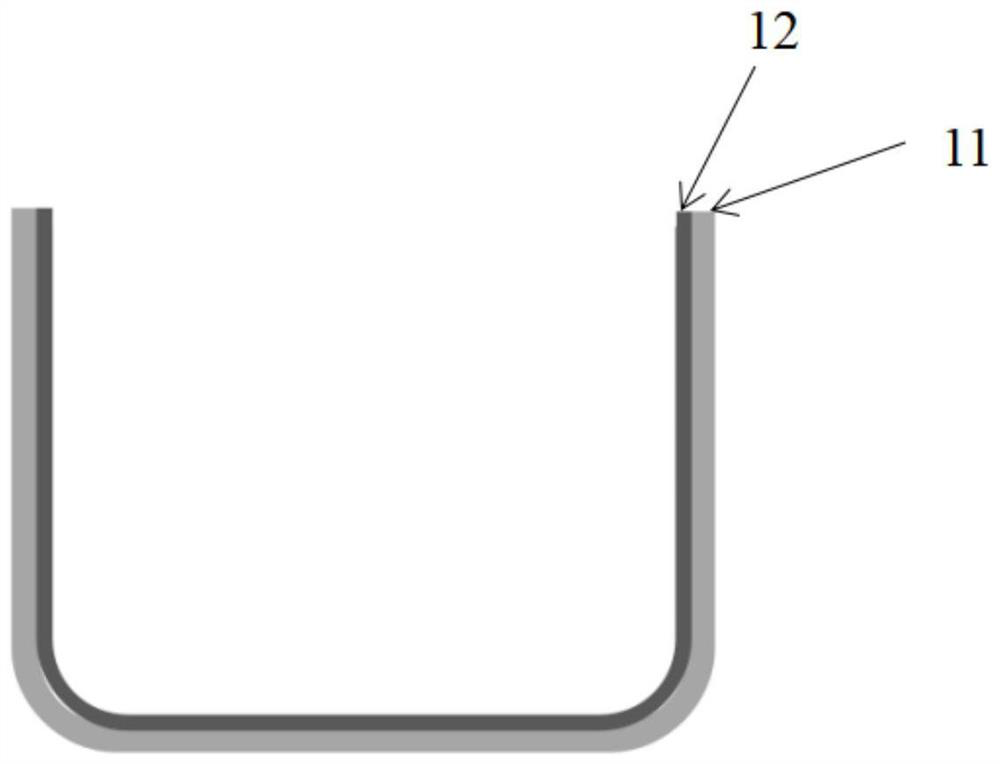

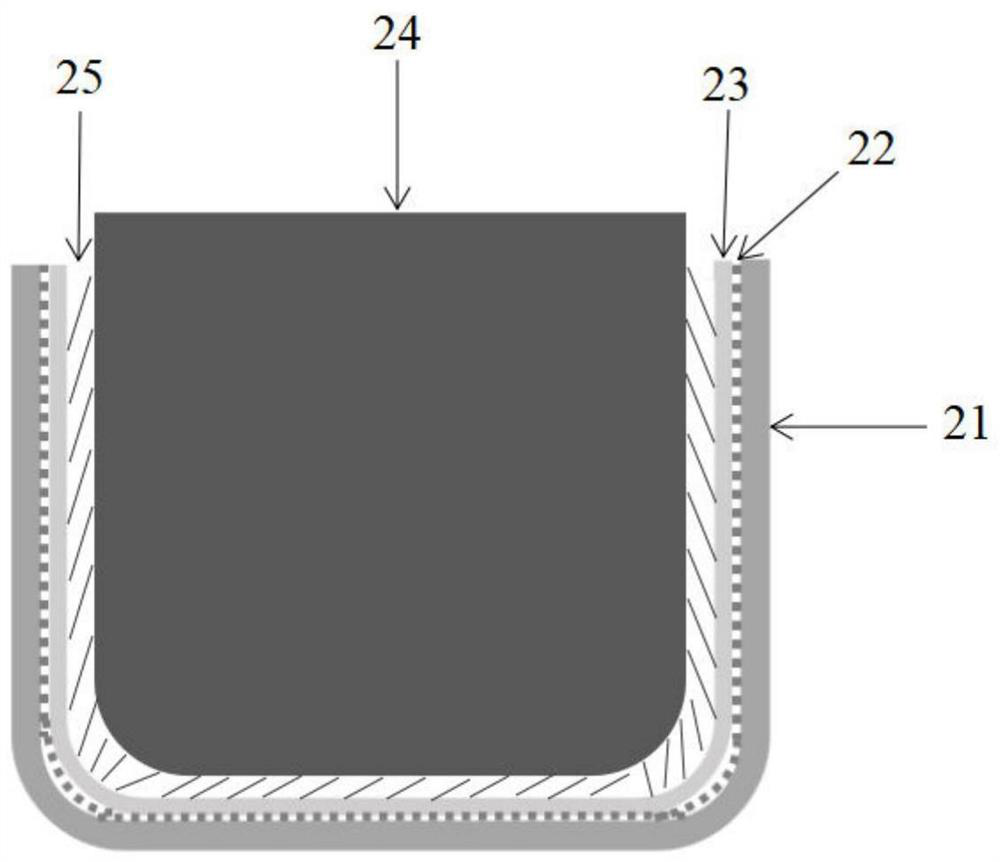

[0045] like figure 1 As shown, a carbon / carbon composite material crucible with a composite ceramic layer of the present invention comprises a carbon / carbon composite material crucible base (11) and a composite ceramic layer (12) respectively attached to its inner surface, which is specifically prepared The steps are as follows:

[0046] Step 1, Preparation of Carbon Fiber Preforms

[0047] According to the shape and size requirements of the crucible, the conventional carbon fiber preform overall felt preparation method is adopted, the non-weft fabric and the mesh layer are alternately stacked, and then the density of 0.2g / cm is prepared by needle punching. 3 carbon fiber preforms;

[0048] Step 2, Densification of Carbon Fiber Preforms

[0049] The carbon fiber preform obtained in step 1 is densified by chemical vapor infiltration (CVI) and propylene as the gas source for chemical vapor deposition, and densified to a density of 1.1 g / cm 3 of carbon / carbon composites;

[...

Embodiment 2

[0067] Step 1, Preparation of Carbon Fiber Preforms

[0068] According to the shape and size requirements of the crucible, the conventional carbon fiber preform overall felt preparation method is used, the non-weft fabric and the mesh layer are alternately stacked, and then the density of 0.6g / cm is prepared by needle punching. 3 carbon fiber preforms;

[0069] Step 2, Densification of Carbon Fiber Preforms

[0070] First, the carbon fiber preform is impregnated-cured and carbonized by means of impregnating furan resin, and then chemical vapor infiltration (CVI) is used for it, using propylene as the gas source for chemical vapor deposition, the carbon fiber obtained in step 1. The preform is densified to a density of 1.4 g / cm 3 of carbon / carbon composites;

[0071] Step 3, machining

[0072] The carbon / carbon composite material obtained in step 2 is subjected to mechanical grinding treatment to obtain a carbon / carbon composite material crucible with a surface roughness Ra...

Embodiment 3

[0088] Step 1, Preparation of Carbon Fiber Preforms

[0089] According to the shape and size requirements of the crucible, the conventional carbon fiber preform overall felt preparation method is adopted, the non-weft fabric and the mesh layer are alternately stacked, and then the density of 0.4g / cm is prepared by needle punching 3 carbon fiber preforms;

[0090] Step 2, Densification of Carbon Fiber Preforms

[0091] First, the carbon fiber preform is impregnated-cured and carbonized by means of impregnating furan resin, and then chemical vapor infiltration (CVI) is used for it, using propylene as the gas source for chemical vapor deposition, and the carbon fiber obtained in step 1 The preform is densified to a density of 1.25 g / cm 3 of carbon / carbon composites;

[0092] Step 3, machining

[0093] The carbon / carbon composite material obtained in step 2 is subjected to mechanical grinding treatment to obtain a carbon / carbon composite material crucible with a surface roughn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com