Production process and cultivation system for cultivating pollution-free bean sprouts by precisely controlling ethylene mixed gas

A production process and mixed gas technology, which is applied in the fields of agricultural gas emission reduction, cultivation, soilless cultivation, etc., can solve the problems of inconsistent germination cycle, different thickness of hypocotyls, difficulty in large-scale production, etc., and improve the appearance of finished products. and taste, improve control accuracy, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

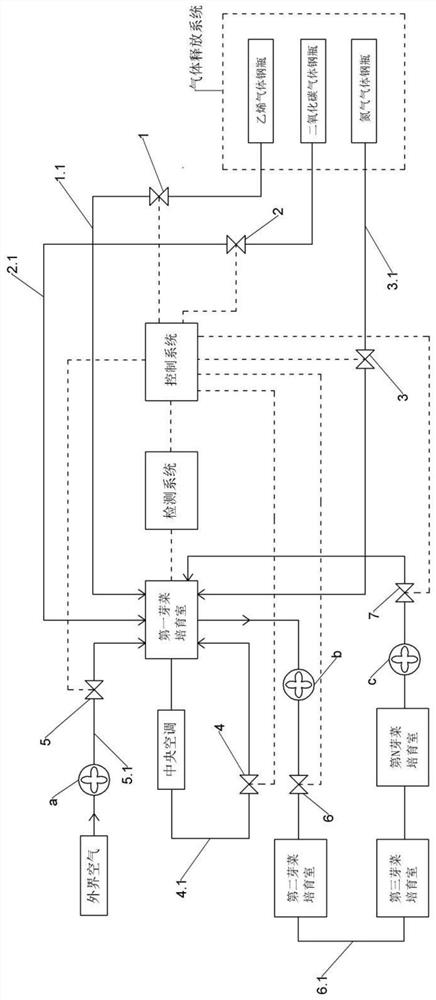

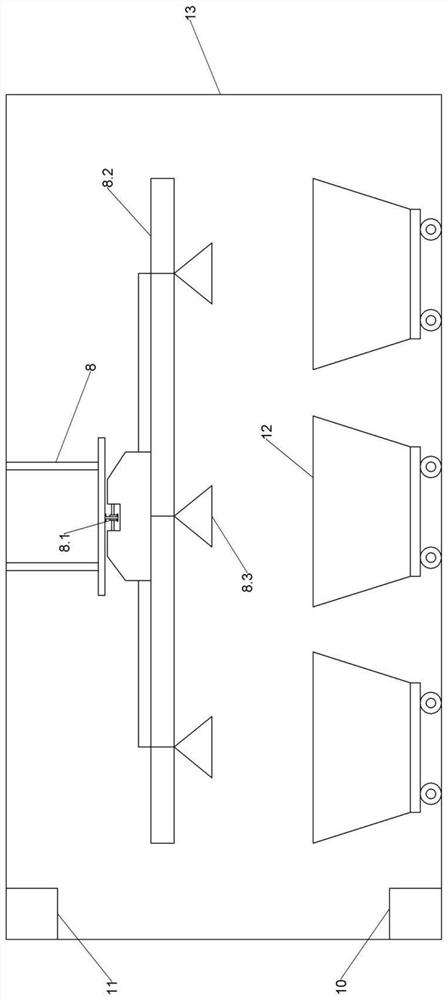

[0044] A kind of cultivation system (such as figure 1 shown), including: sprout cultivation room, central air conditioner, gas release system, detection system, control system, external circulation axial flow fan, internal circulation axial flow fan, and air supply duct. The gas release system includes ethylene gas cylinders, carbon dioxide gas cylinders, and nitrogen gas cylinders; the number of sprout cultivation rooms is 1 to N, and N≥2.

[0045] The first sprout cultivation room is connected to the ethylene gas cylinder through the first air supply pipeline and solenoid valve switch 1, connected to the carbon dioxide gas cylinder through the second air supply pipeline and solenoid valve switch 2, and connected to the carbon dioxide gas cylinder through the third air supply pipeline and solenoid valve switch 3 is connected to the nitrogen gas cylinder, connected to the central air conditioner through the fourth air supply pipe and solenoid valve switch 4, and connected to t...

Embodiment 2

[0055] A production process for precisely controlling ethylene mixed gas to cultivate pollution-free bean sprouts, comprising the following steps:

[0056] (1) Cleaning: Wash the soybean raw material with normal temperature water to remove dead beans and impurities in the soybean raw material;

[0057] (2) Sterilization: Soak and sterilize soybean raw materials with natural plant fungicides. The concentration of natural plant fungicides is 0.03g / mL, the sterilization time is 2 hours, and the sterilization temperature is 20°C; the natural plant fungicides are tea poly A mixture of phenol, propolis, and sesame flower extract, wherein the mass ratio of tea polyphenols, propolis, and sesame flower extract is 1:1:1.

[0058] The preparation method of the sesame flower extract: adopt the alcohol extraction method, weigh the dry sesame flower powder raw material by weight, add 5 to 10 times the volume concentration of ethanol with a volume concentration of 95% of the raw material wei...

Embodiment 3

[0067] A production process for precisely controlling ethylene mixed gas to cultivate pollution-free bean sprouts, comprising the following steps:

[0068] (1) Cleaning: Wash the soybean raw material with normal temperature water to remove dead beans and impurities in the soybean raw material;

[0069] (2) Sterilization: use natural plant fungicides to soak and sterilize soybean raw materials, wherein the concentration of natural plant fungicides is 0.04g / mL, the sterilization time is 2h, and the sterilization temperature is 20°C; the natural plant fungicides are Neem The mixture of ethanol extract, propolis and sesame flower extract, the mass ratio of neem ethanol extract, propolis and sesame flower extract is 3:1:1.

[0070] The preparation method of sesame flower extract and neem fruit ethanol extract is the same: take dry neem fruit coarse powder or dry sesame pollen raw material by weight, add 95% ethanol with volume concentration 5 to 10 times of raw material weight, Re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com